Automatic ignition and temperature control method for aviation kerosene and gas generator

一种燃气发生器、航空煤油的技术,应用在控制燃烧、照明和加热设备等方向,能够解决影响温度控制精度、不能准确控制油/气比、不能实现连续自动控制等问题,达到方便自动、高参数控制精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

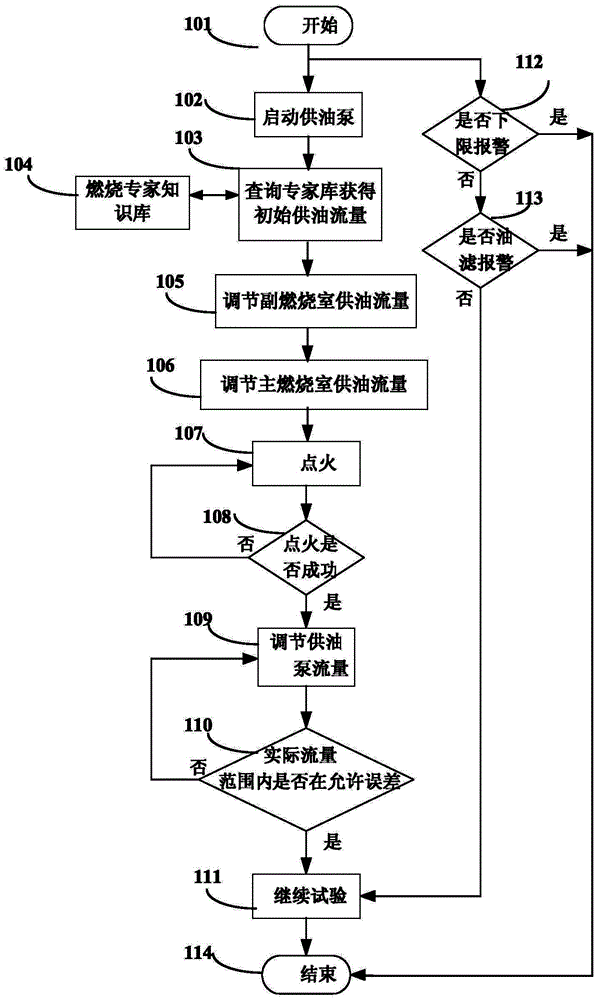

[0013] figure 1 Shown is a flow chart of the automatic control ignition method according to an embodiment of the present invention. The process includes:

[0014] The start step (101) mainly includes data initialization,

[0015] Carry out the judgment of lower limit alarm (112), if the oil supply has reached the lower limit, then terminate the operation and enter the exit step, otherwise enter the oil filter alarm (113) judgment, if the oil filter alarm, then terminate the operation and enter the exit step. If there are no two alarms, start the oil pump and carry out the (102) step, and obtain the initial oil supply flow (103) step by querying the expert database. Query the oil supply expert database (104), and adjust the fuel flow of the auxiliary combustion chamber (105) and the fuel flow of the main combustion chamber (106) to be the ignition flow. Start ignition (107), including setting timer (as setting 45s) and opening auxiliary combustion chamber, main combustion ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com