Checking tool and testing method for rear door and window step gap of body-in-white

A technology of level difference, doors and windows, applied in the field of car body assembly testing devices, can solve the problems of low measurement accuracy and measurement efficiency, generate wind noise, affect car comfort, etc., achieve high measurement accuracy and measurement efficiency, easy assembly and disassembly, Simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

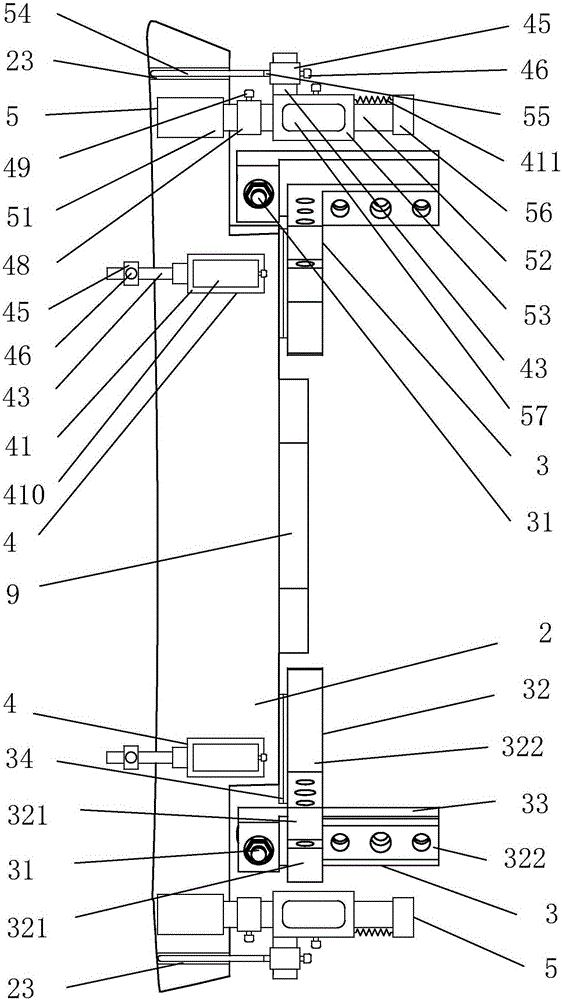

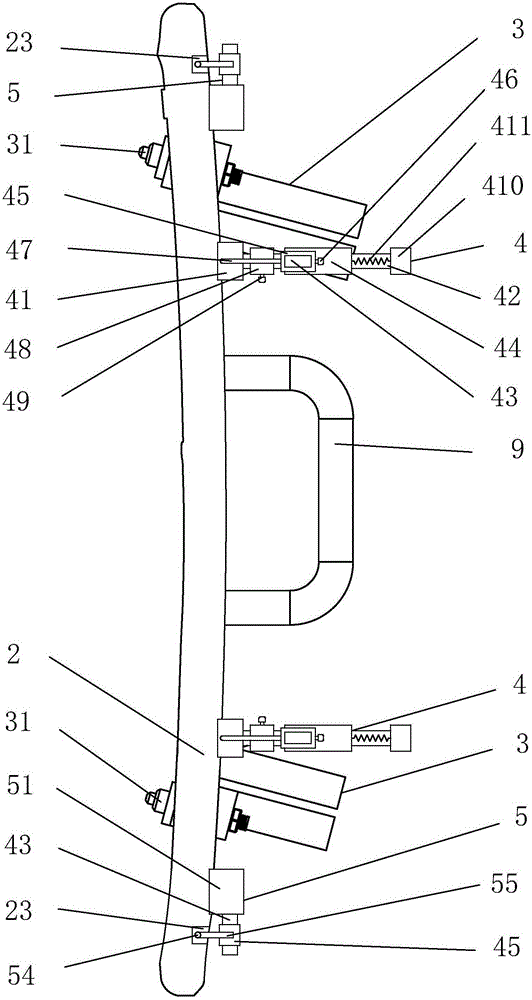

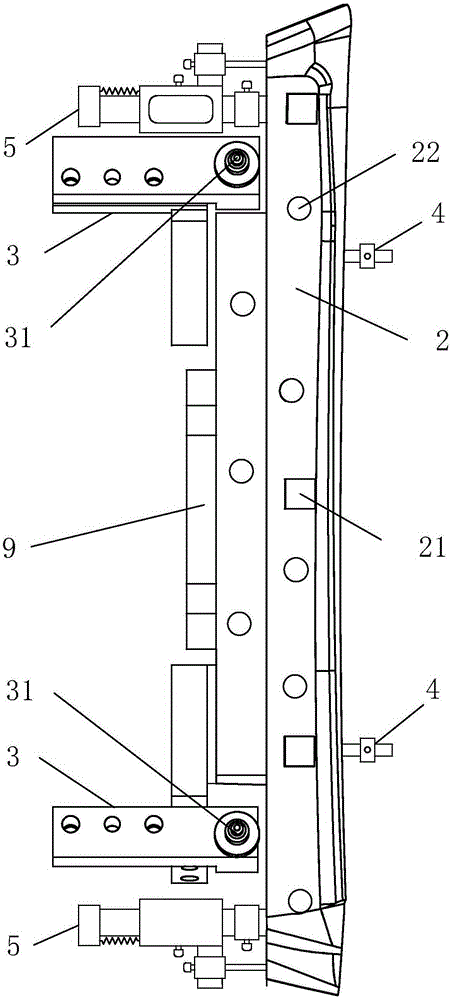

[0022] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a kind of body-in-white rear door and window step gap inspection tool, including bottom plate 2 with positioning surface 21 and eight suction heads 22, two each have a positioning hole on the rear triangular window frame 1 (attached Not shown in the figure) the positioning block 3 of the positioning pin 31 with clearance fit, two level difference gauges 4 and two section gauges 5; even.

[0023] In this embodiment, the suction head 22 is magnetic steel. There are three positioning surfaces 21 arranged in a row.

[0024] The positioning block 3 includes two connecting blocks 32 and a fixed bar 33; the connecting block 32 includes a vertical bar 321 and a horizontal bar 322 with one end connected to the lower end of the vertical bar 321; between the horizontal bars 322 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com