Electrolyzer device based on on-line electrochemical measurement of transmission line

A technology of transmission lines and online electricity, which is applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve problems such as the adverse effects of transmission lines and the difficulty of online measurement, and achieve the realization of online electrochemical measurement, avoid adverse effects, and rapid determination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

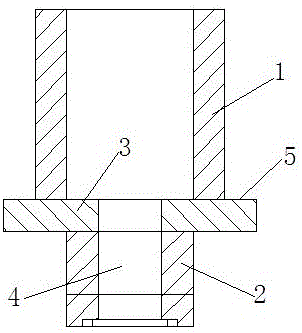

[0031] Refer to attached figure 1 , an electrolytic cell device based on the online electrochemical measurement of the transmission line, including an electrolytic cell and a fixing clip, etc., wherein the electrolytic cell includes an electrolyte container 1 with an upward opening, a workpiece connection part 2 and a square partition 3, and the electrolyte container 1 It is a square columnar structure, which is surrounded by four plates with a certain thickness. The bottom end surface and the square partition 3 are fixedly connected by glue, thus forming a square container with the square partition as the bottom. At this time, the square partition The area of the plate 3 is larger than the cross-sectional area of the electrolyte container 1 , and its periphery protrudes to form a square ring-shaped boss 5 . The workpiece connection part 2 is a columnar member, which can be a square columnar member or a cylindrical member. A cylindrical through hole 4 is opened along the c...

Embodiment 2

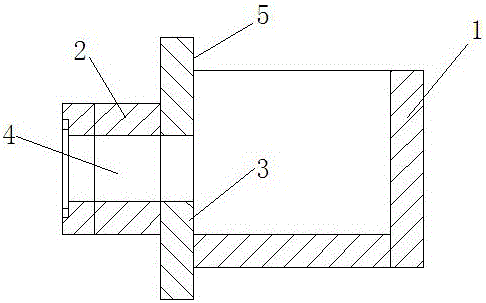

[0035] Refer to attached figure 2, the electrolyte container 1 is a square columnar structure, which is surrounded by four thick plates and square partitions. At this time, the square partition 3 is used as the side panel of the electrolyte container 1, and the remaining four thick plates are the other three Side panels and a bottom plate, the workpiece connection part 2 is located on the outer surface of the square partition 3, and its axis is perpendicular to the axis of the electrolyte container 1. Such a structure is suitable for electrochemical measurement when the measured surface of the metal component is a vertical surface. The workpiece connecting portion is transversely perpendicular to the surface of the workpiece, and its cylindrical through hole also passes through the square partition and communicates with the inner cavity of the electrolyte container. The parts not described in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com