Preparation method of soft clay flower strip

A technology of soft clay and flower strips, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of monotonous color, rough production process, poor combination, etc., achieve simple and practical production methods, save noodle press links, and methods simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

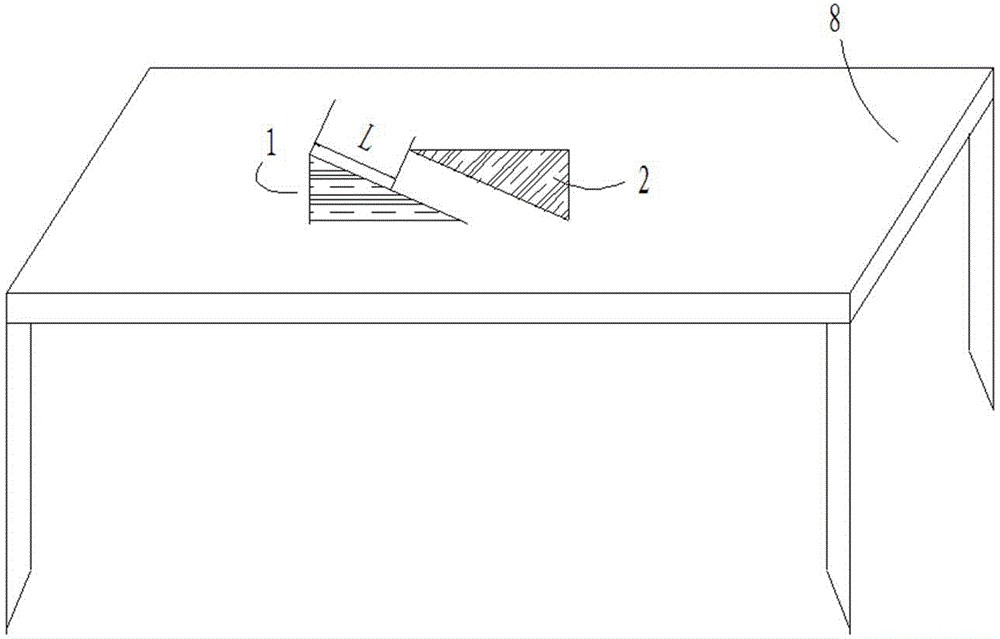

[0036] like figure 1 Shown, the preparation method of soft clay flower strip, comprises the following steps:

[0037] 1. Select soft clay: select the desired color according to different flower strips, determine the quantity of the whole piece of soft clay required by different colors, remove the soft clay outer packaging, and remove the soft clay that is polluted by dust; the present invention chooses white clay Color clay with the same ratio of two colors as red;

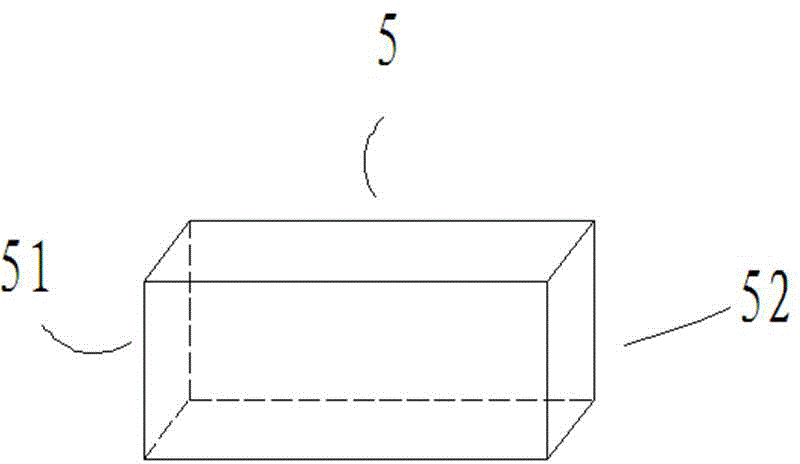

[0038] 2. Knead soft clay of different colors separately to form a cuboid shape, such as figure 2 , so that it is fully softened for use; soften and knead the soft clay by kneading to prevent uneven gaps caused by uneven texture during the production process;

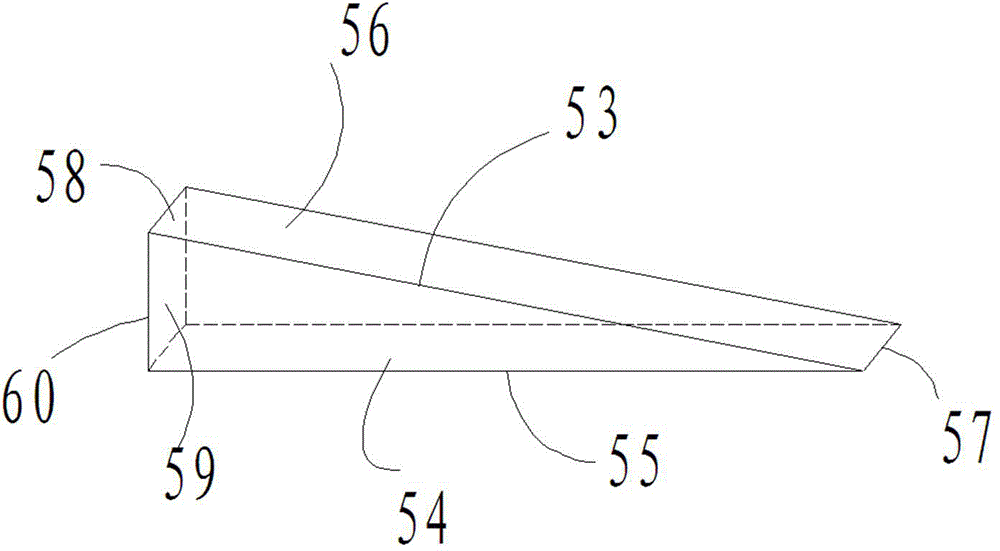

[0039] 3. If figure 2 , image 3 , kneading two cuboids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com