Scraper for silk-screen printing

A technology of screen printing and squeegee applied in the direction of screen printing machines, printing machines, printing machines, etc., which can solve the problems of uneven pressure, unevenness, and less pressure, so as to ensure normal operation, improve product quality, and improve consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

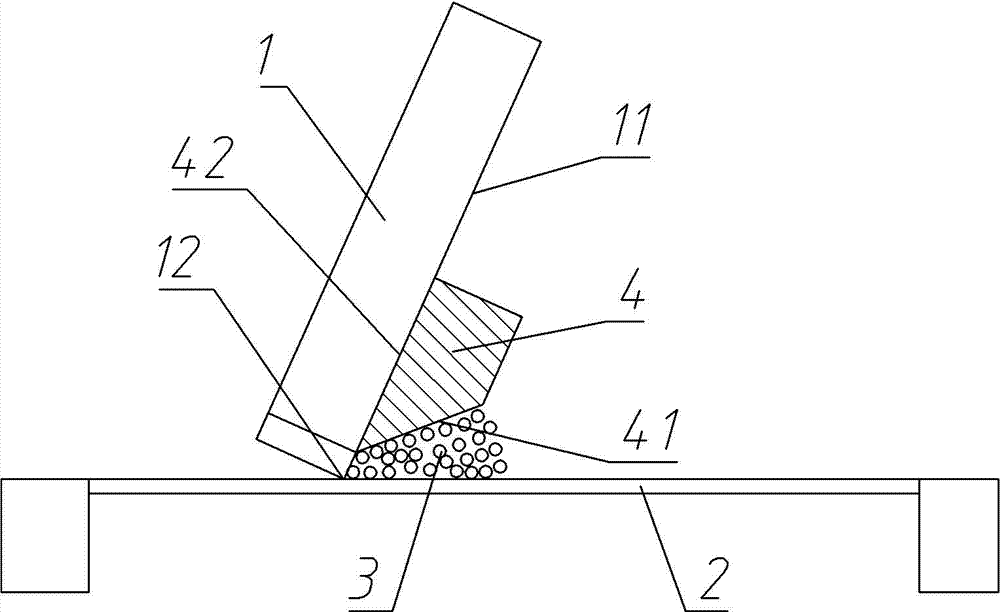

[0015] An example of a scraper for screen printing of the present invention is figure 2 As shown, it is a screen printing scraper used for printing ink on the display screen of a mobile phone, including a main scraper plate 1 and an auxiliary scraper plate 4, and the main scraper plate 1 is a cuboid plate made of polyurethane rubber with a hardness of 80 shape, including the front surface 11 facing the forward direction of the main scraper plate 1, and the bottom edge 12 for pressing the screen plate 2, the part of the front surface 11 close to the bottom edge 12 is the rake surface. The auxiliary doctor blade 4 is arranged on the front surface 11 of the main doctor blade 1 .

[0016] The above-mentioned auxiliary scraper plate 4 is a block made of polyurethane rubber with a hardness of 60, and its cross-section is a right-angled trapezoid. It forms an inclined pressure surface 41 with an angle smaller than the angle between the front surface 11 and the screen plate 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com