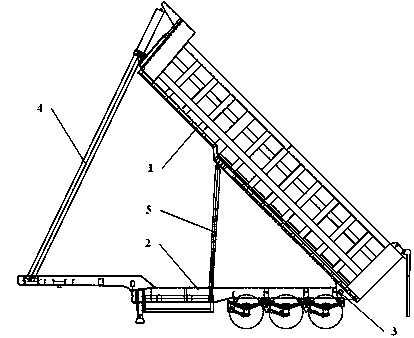

Reinforced semitrailer back-tipping carriage

A reinforced, self-unloading technology, which is applied in the direction of inclined load-carrying vehicles, vehicle parts, and substructures, etc., can solve the problems of large impact force, large amplitude of left and right bumps, easy to break from here, etc., so as to prolong the service life, left and right Shake reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

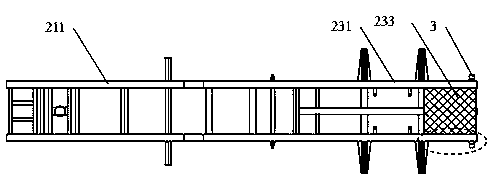

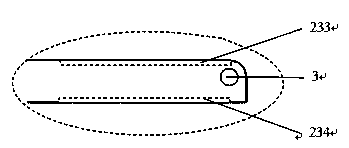

[0021] Others are the same as the prior art, except that the two main longitudinal beams 231 adjacent to the rear part 23 of the main frame are consolidated together by the upper cover plate 233 and the lower cover plate 234 close to the pin shaft 3 .

Embodiment approach 2

[0023] Others are the same as the prior art, except that the auxiliary beams 132 at the rear part 13 of the auxiliary frame are of full length, and the auxiliary longitudinal beams 131 are distributed between the auxiliary beams 132 at intervals.

Embodiment approach 3

[0025] Others are the same as Embodiment 1 or Embodiment 2, except that the auxiliary longitudinal beam 111 of the front part 11 of the auxiliary frame is a structure with an inlay groove, and the width H1 of the inlay groove is greater than the width H2 of the main longitudinal beam 211 of the front part 21 of the main frame. The main longitudinal beam 211 is embedded in the inlay groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com