Garbage bag mouth fixing mechanism

A technology of fixing mechanism and garbage, applied in the direction of trash cans, garbage collection, household appliances, etc., can solve the problems of high manufacturing cost of the collar, loss of the function of garbage bag, damage to the collar, etc., and is not easy to be damaged and lost, and the manufacturing cost is low. , the mechanism is stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

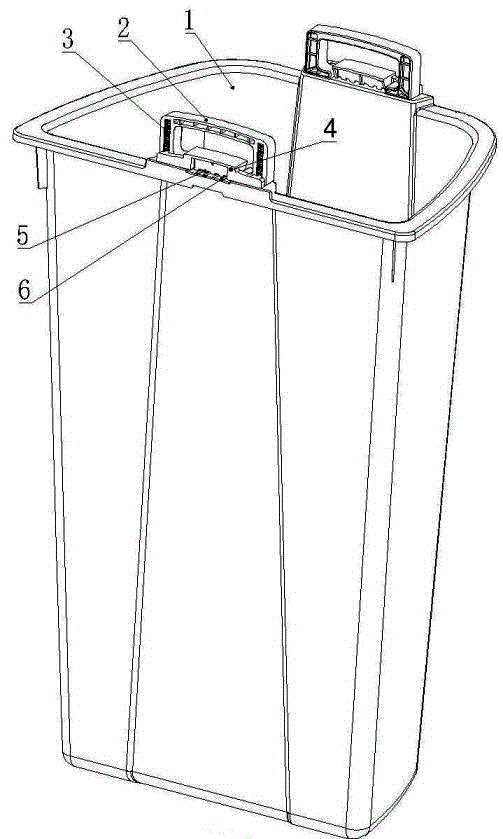

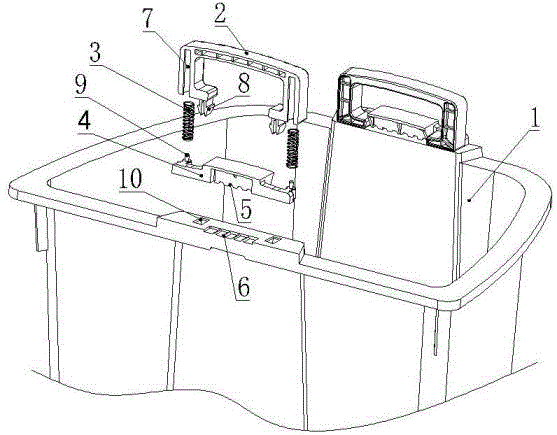

[0015] Example 1: In figure 1 , figure 2 Among them, the upper end of the trash can a1 is equipped with a handle 2, the handle 2 is equipped with a bead a4, and a spring 3 is arranged between the handle 2 and the bead a4. During the installation process, first put the two springs 3 on the bosses 9 at both ends of the bead a4, then insert the spring 3 into the chute 7 of the handle 2, and then snap the buckle 8 of the handle 2 into the buckle of the trash can a1 In hole 10. Under the action of the spring 3, the bead tooth opening a5 and the garbage bin tooth opening a6 are engaged with each other. So far the installation is complete.

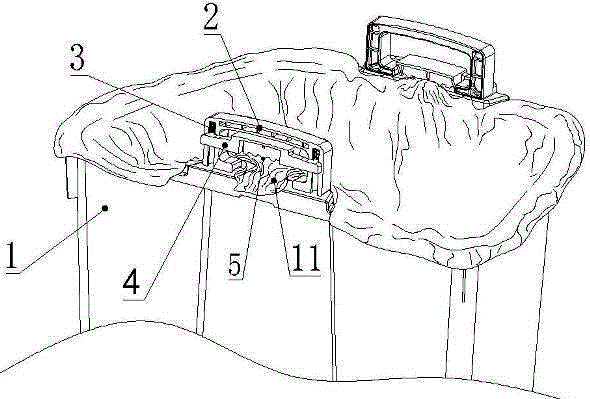

[0016] When used, such as image 3 As shown, put the garbage bag 11 in the garbage can a1, pull up the bead a4 with your hand, hold the end of the garbage bag 11 with the other hand and pass it between the bezel a5 and the garbage can a6, and then release it. Press bar a4, under the action of spring 3, garbage bag 11 is fixed on the port of...

Embodiment 2

[0017] Example 2: In Figure 4 , Figure 5 Among them, the upper end of the trash can b12 is equipped with a bead b13. Among them, the bead b13 is provided with a guide post 14, and the garbage bin b12 is provided with a guide post hole 16. Insert the guide post 14 into the guide post hole 16, then load the spring 3 from the lower end of the guide post hole 16, and finally screw the screw 18 on the guide post. 14. At the lower end, the spring 3 is fixed between the bead b13 and the trash can b12, so that the bezel tooth opening b15 is engaged with the trash can tooth mouth b17.

[0018] When used, such as Image 6 As shown, put the garbage bag 11 in the garbage can b12, pull up the bead b13 with your hand, hold the end of the garbage bag 11 with the other hand and pass between the bezel tooth opening b15 and the garbage can tooth mouth b17, and then release it Press bar b13, under the action of spring 3, garbage bag 11 is fixed on the port of garbage bin b12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com