Non-stick tool with two mutual inductors placed on tray

A transformer, self-recombination technology, used in transportation and packaging, mechanical conveyors, conveyors, etc., to achieve the effect of convenient operation, improve work efficiency, and prevent shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

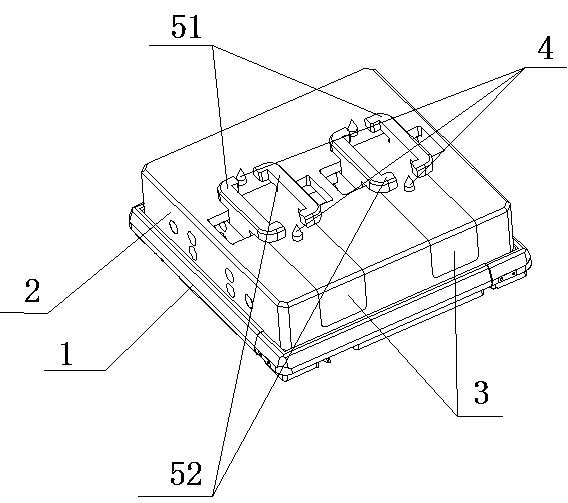

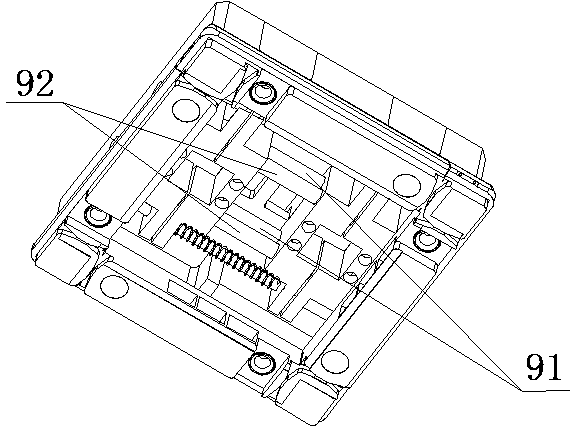

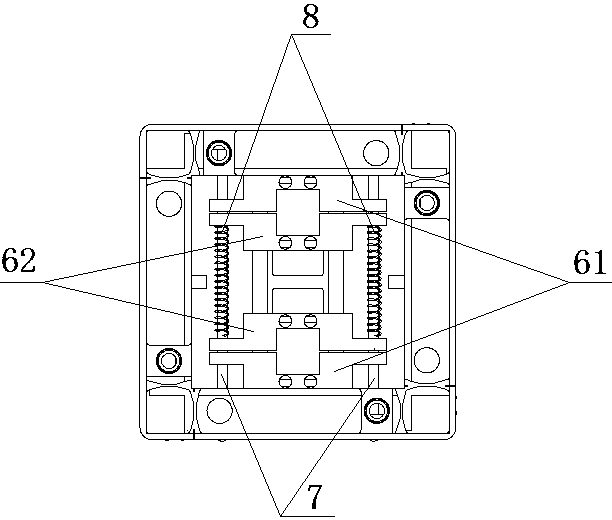

[0022] Such as figure 1 - image 3 As shown, the tooling pallet of the present invention includes: a tooling base 2, two grounded aluminum plates 3, four positioning pins 4, two pairs of identical movable clamps 51, 52 that can be opened and closed, and two movable clamps 51 are fixed on the movable clamps by screws. On the connecting block 61 , two movable clamps 52 are fixed on the movable connecting block 62 by screws, the movable connecting block 61 is fixedly connected through the connecting column 91 , and the movable connecting block 62 is fixedly connected through the connecting column 92 .

[0023] The four movable clips 51, 52 protrude from the upper surface of the tooling base, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com