Compressing device in solidification process of glue for main grating glass ruler and ruler shell of grating ruler

A technology of a pressing device and a glass ruler, which is applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of affecting the bonding strength of the colloidal layer, not easy to control accurately, uneven pressing, etc., and achieve less pressing and unloading The effect of reducing the time for pressing the structure, easy operation, and improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

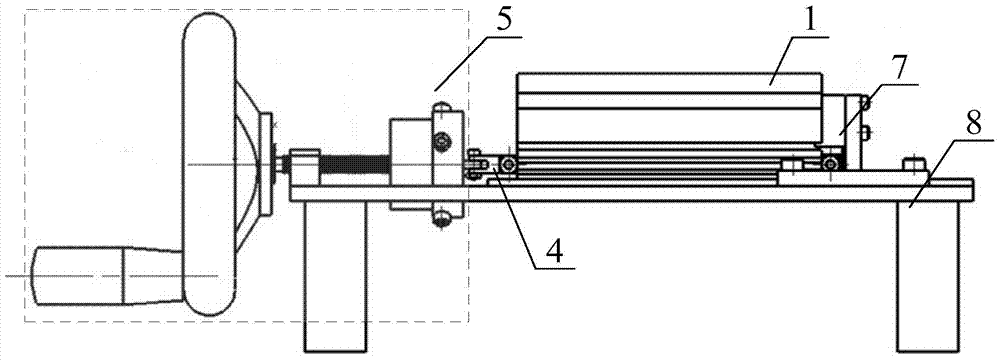

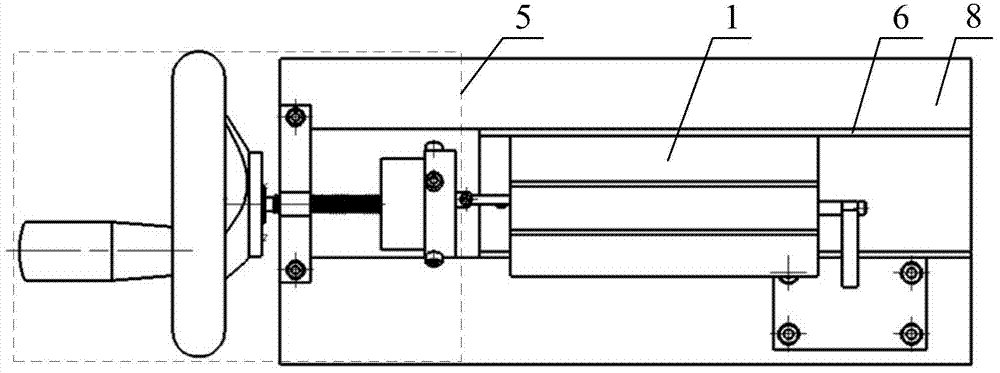

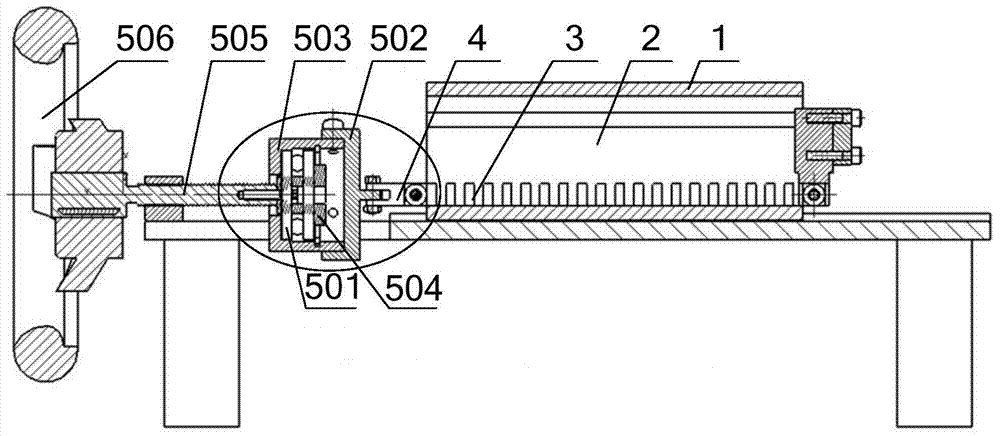

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] See attached figure 1 , attached figure 2 And attached image 3 , the pressing device of the present invention in the process of gluing and curing the main grating glass ruler of the grating ruler and the ruler shell includes a wave spring 3, a tension mechanism 5, a guide rail 6 and a fixing structure 7; the fixing structure 7 is fixed on a belt with a guide rail 6 on the fixed platform 8, the tensioning mechanism 5 is connected with the nut fixed on the fixed platform 8 through the threaded rod 505 of the tensioning mechanism 5, the center line of the guide rail 6 is connected with the tensioning mechanism 5 and the fixed structure 7 The center line between them is located on the same vertical plane, one end of the wave spring 3 is hung on the fixed structure 7, the other end is connected with the tensioning mechanism 5 through the movable li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap