Dry friction type double clutch of automatic transmission

An automatic transmission and dual clutch technology, applied in the direction of friction clutch, mechanical drive clutch, clutch, etc., can solve the problems of discontinuous vehicle speed, poor driving comfort, slowing down of vehicle speed, etc., and achieve improved driving comfort performance, small structural space, and design compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

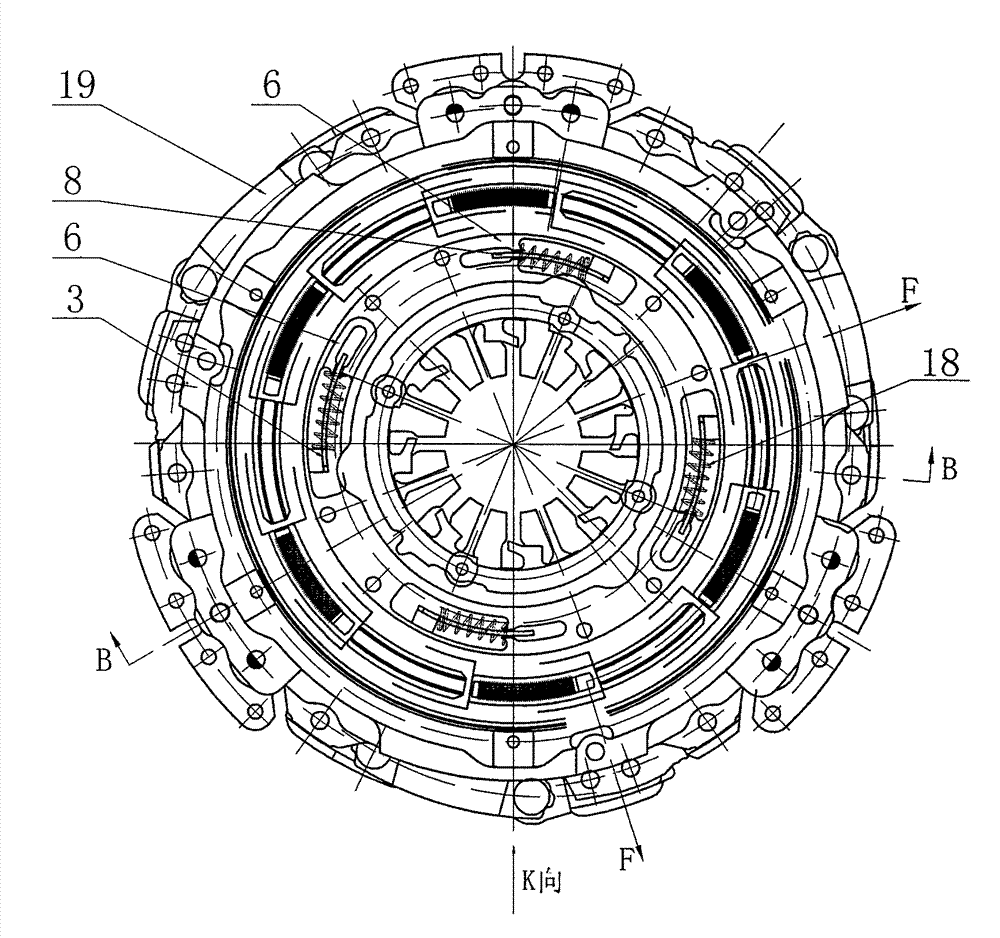

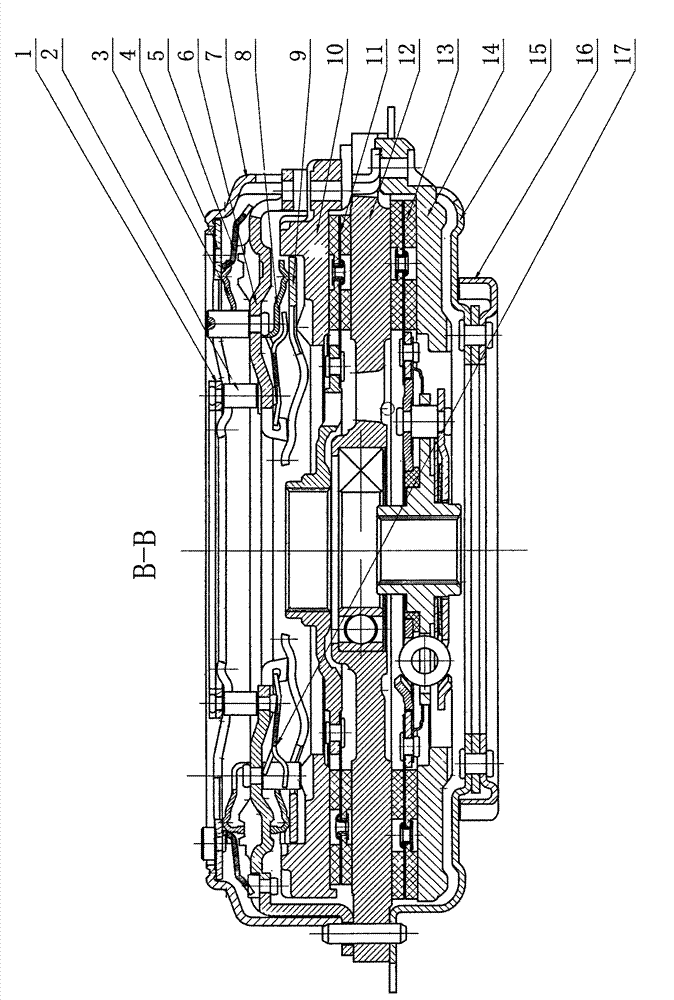

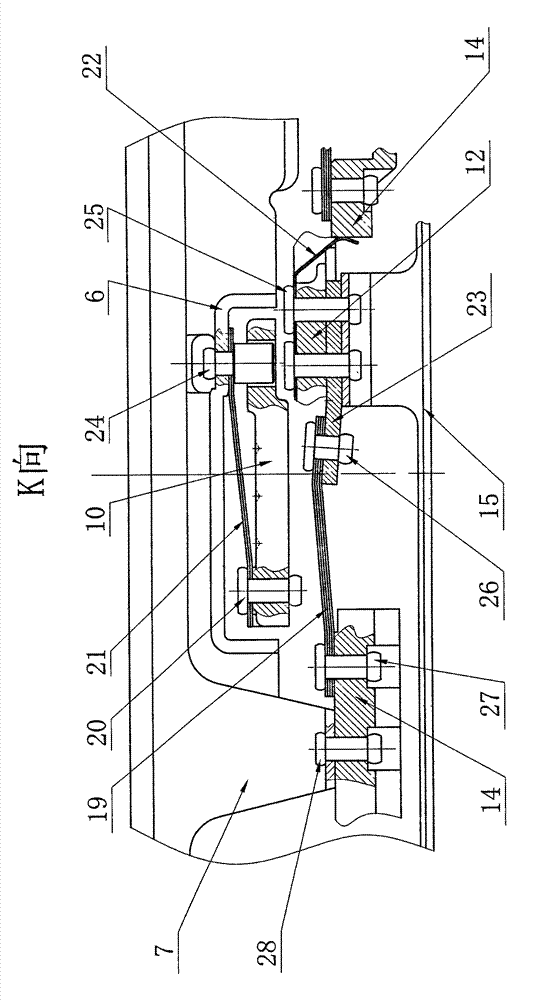

[0018] see figure 1 , figure 2 , image 3 , the dry friction double clutch of the automatic transmission of the present invention comprises a clutch cover assembly and a driven plate assembly, and the pressure plate of the clutch cover assembly consists of a first pressure plate 10, a second pressure plate 12, a third pressure plate 14, the driven disk assembly is composed of a first driven disk assembly 11 and a second driven disk assembly 13 (the first driven disk assembly 11 and the second driven disk assembly 13 are respectively installed Between the first pressure plate 10 and the second pressure plate 12, between the second pressure plate 12 and the third pressure plate 14), the diaphragm spring of the clutch cover assembly is composed of the first diaphragm spring 4, the second The diaphragm spring 9 is composed of the second diaphragm spring 9 mounted on the first pressure plate 10, and the first diaphragm spring 4 is mounted on the clutch of the clutch cover assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com