A multi-point liquid level detection circuit

A liquid level detection and circuit technology, which is applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of short sliding resistance sliding arm, inaccurate liquid level position, high cost, etc., and achieve simple and compact circuit structure and low electrical requirements , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

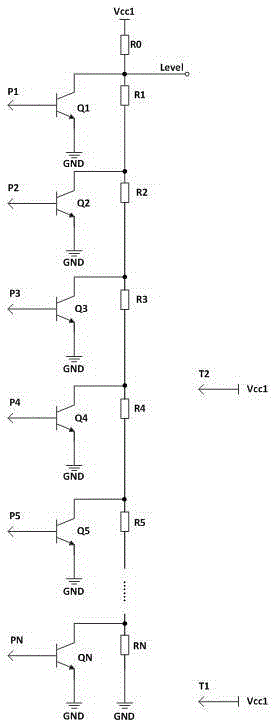

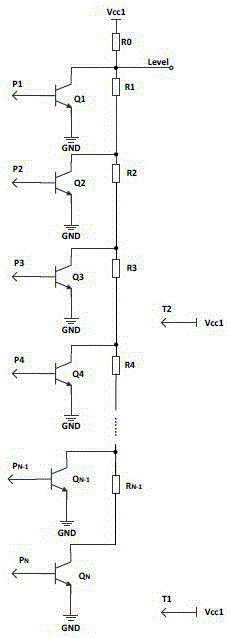

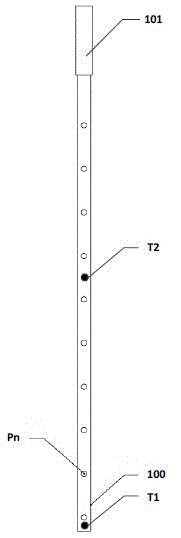

[0038] see figure 1 , is a schematic circuit diagram of an embodiment of the multi-point liquid level detection circuit provided by the present invention.

[0039] The multi-point liquid level detection circuit provided in this embodiment includes: a voltage dividing resistor, a resistance circuit composed of N resistors in series, and N transistors corresponding to each series node of the resistance circuit; One end of the resistance circuit is connected to the ground terminal, and the other end is the liquid level voltage output end; N is a positive integer.

[0040] In this embodiment, the output voltage of the liquid level voltage output terminal Level is proportional to the resistance value in the resistance circuit, and the resistance value R of the resistor at the mth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com