Driving system and driving method of planar organic electroluminescent device

A driving system and luminescent technology, applied in electroluminescent light sources, electric light sources, lighting devices, etc., can solve the problems of the light emitting device 100 being uncut, high cost, and long production cycle, so as to achieve good luminous efficiency and avoid electric shock Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

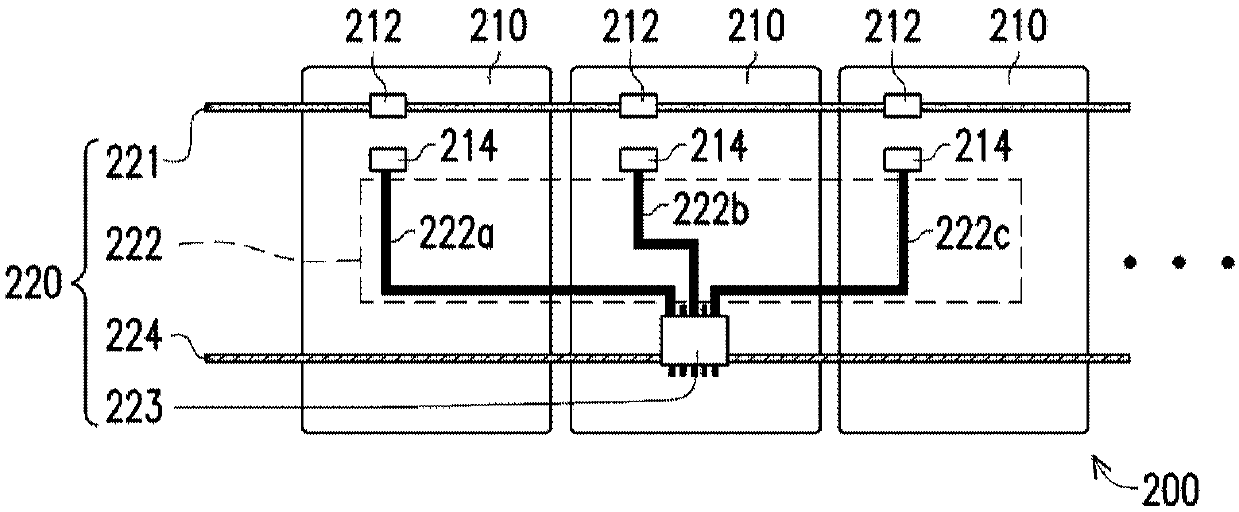

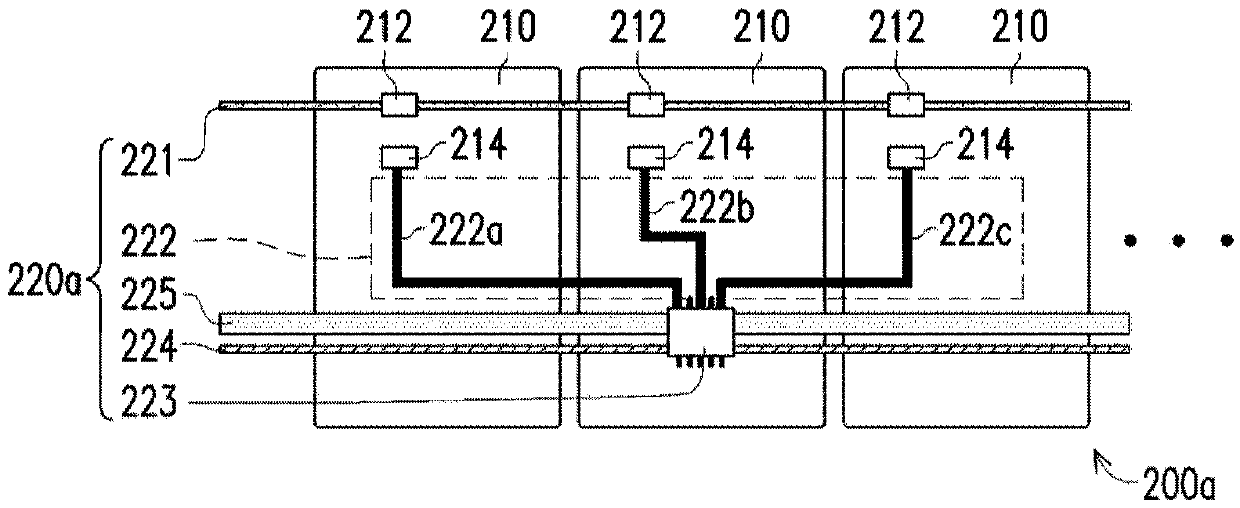

[0079] figure 2 It is a schematic diagram of a planar organic electroluminescent device and a driving system of the planar organic electroluminescent device according to an embodiment of the present invention. Please refer to figure 2 , the planar organic electroluminescent device 200 may have a plurality of light emitting elements 210 , and each light emitting element 210 has a first electrode 212 and a second electrode 214 . The first electrode 212 can be an anode (+) for inputting holes, and the second electrode 214 can be a cathode (−) for inputting electrons. Electrons and holes are combined in the light-emitting layer of the light-emitting element 210 to emit light. The light emitting element 210 may be an organic electroluminescence element. When the light-emitting element 210 uses an organic electroluminescent element, it can be fabricated in a large area, and has flexibility and cutability.

[0080] please refer again figure 2 , the driving system 220 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com