High-voltage electric capacitor

A high-voltage power and capacitor technology, applied in the field of capacitors, can solve the problems of high height of high-voltage capacitors, inconvenient transportation of fixed seats, affecting appearance, etc., and achieves the effect of stable center of gravity, simple and reasonable structure, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

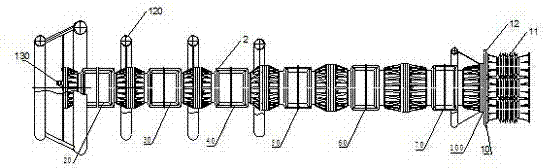

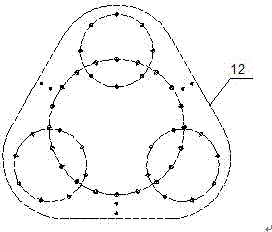

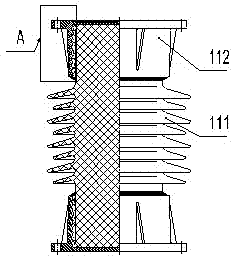

[0018] Such as figure 1 A high-voltage power capacitor shown includes a base 10 and a first-section insulator 20 , a second-section insulator 30 , a third-section insulator 40 , and a fourth-section insulator installed on the base 10 in order of decreasing diameter from top to bottom. 50. The fifth section insulator 60 and the sixth section insulator 70, the diameters of the six section insulators from top to bottom are: 610mm, 610mm, 665mm, 705mm, 715mm, 715mm, and the heights are: 2350mm, 2350mm, 2350mm, 2350mm , 2350mm, 2450mm; the base 10 includes three post insulators 11 distributed in an equilateral triangle and a support 12 arranged on the upper end of the post insulator; the diameter of the post insulator 11 is 356mm, and the height is 657-659mm; the post insulator 11 includes a solid Porcelain sleeve 111 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com