Wiping device, in particular wiping device for a motor vehicle pane

A technology for motor vehicles, glass scraping, applied in the direction of vehicle maintenance, vehicle cleaning, transportation and packaging, etc., to avoid seams and/or noise and flow resistance, durable connection, and weight saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

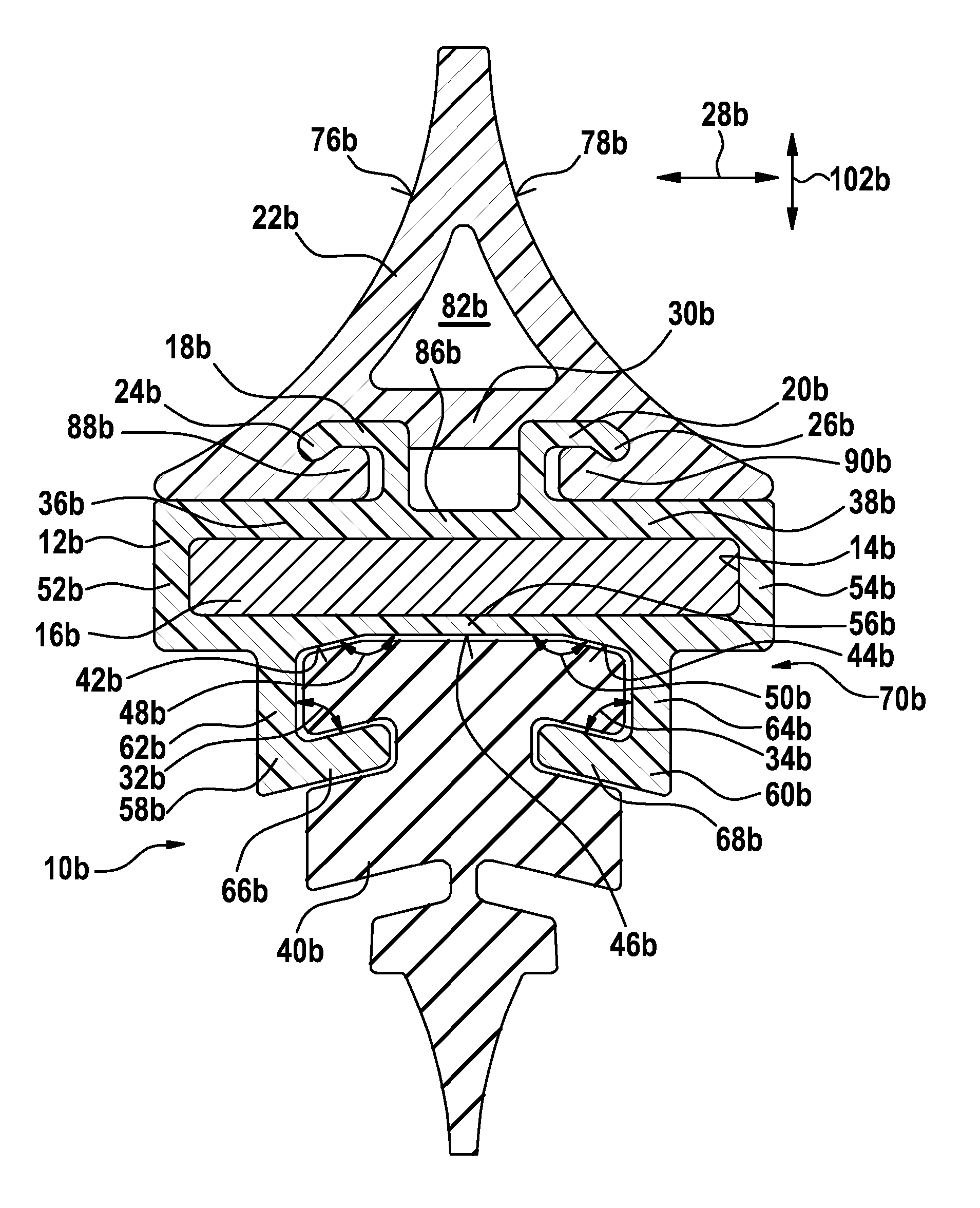

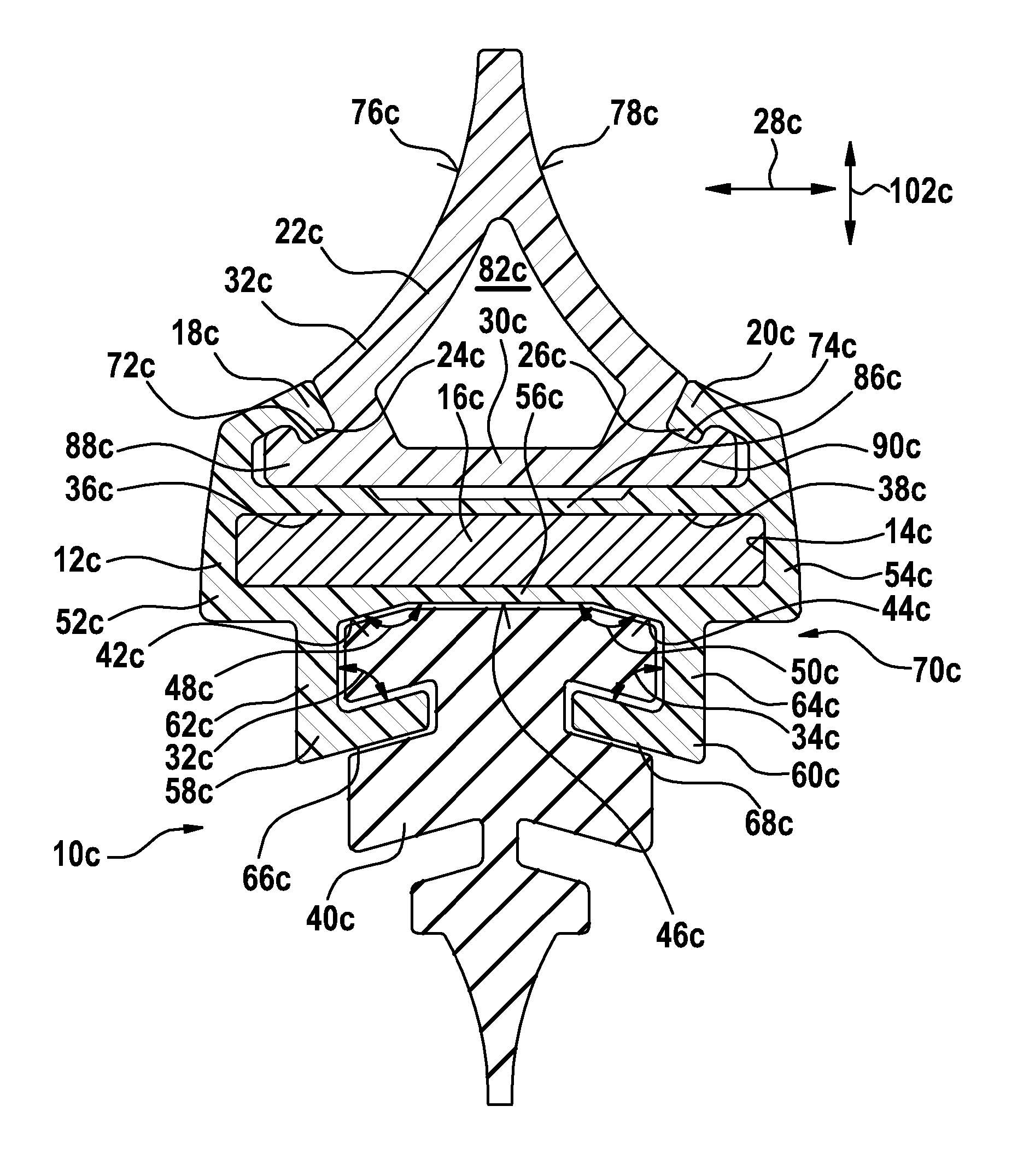

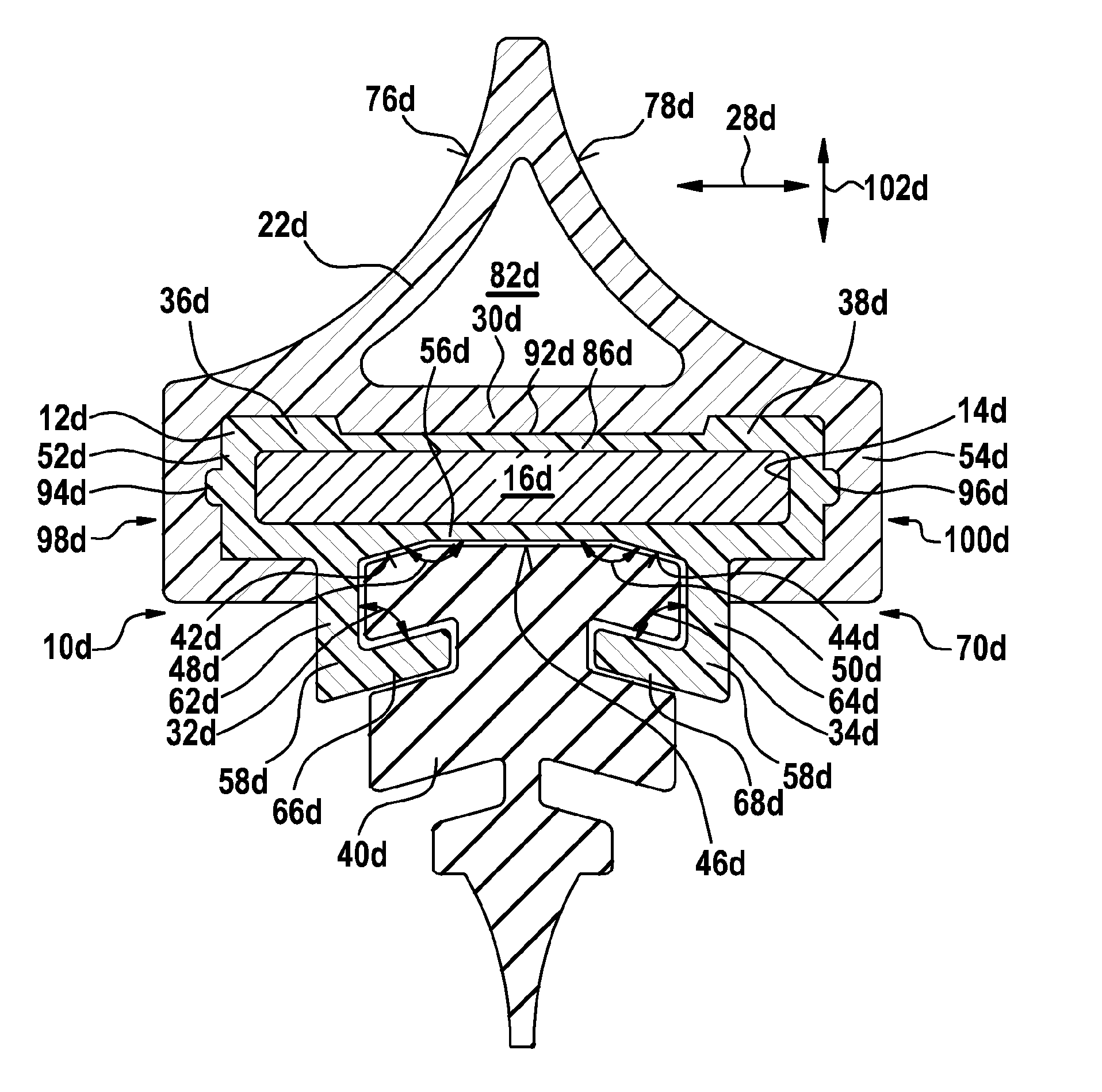

[0020] figure 1 Shows a sectional view of an exemplary embodiment of a windshield wiper device according to the invention having a holding unit 10a with a holding element 12a having a spring element 16a for guiding a The longitudinal guide channel 14a. This section plane is perpendicular to the longitudinal extension of the holding element 12a.

[0021] The holding element 12a has two fastening means 18a, 20a. The fastening means 18a, 20a are formed in one piece with the holding element 12a. The fastening means 18a, 20a point at their free ends 24a, 26a in directions facing away from each other. Furthermore, the fastening means 18a, 20a form two channel walls 36a, 38a which adjoin the longitudinal guide channel 14a on a side facing away from the wiper strip. The fastening means 18a, 20a bend at their free ends 24a, 26a towards the longitudinal guide channel 14a. The ends 24a, 26a are enclosed by a wind deflector element 22a. For this purpose, the wind deflector element 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com