Portable manual rapid disassembly and assembly tool for snap-on run-flat tires

A technology of explosion-proof tires and assembly tools, which is applied in tire installation, tire parts, transportation and packaging, etc. It can solve the problems of large pressure required for assembly and disassembly, the vehicle cannot be used continuously, and the structure of the tire group is complicated, so as to avoid Equipment damage, avoid personal injury, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

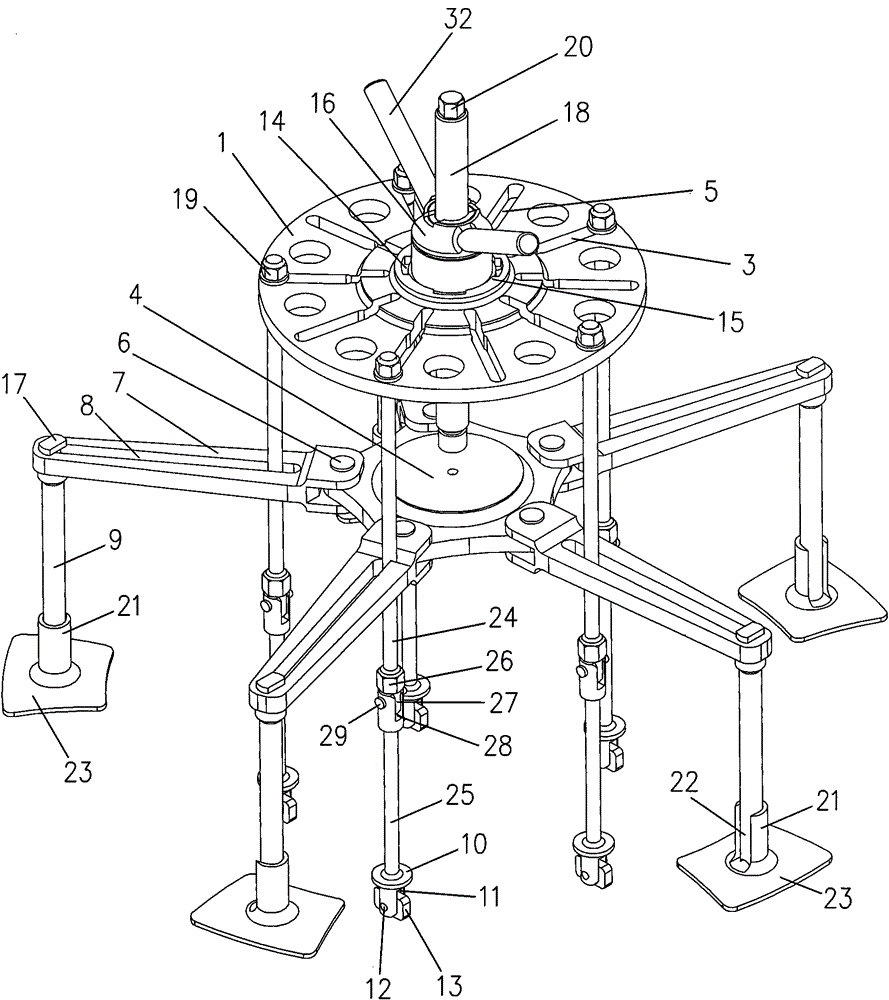

[0024] The snap-lock type explosion-proof tire portable manual quick disassembly assembly tool of the present invention can be unpacked and stored when not in use, and then assembled into a figure 1 with Figure 4 The structure shown.

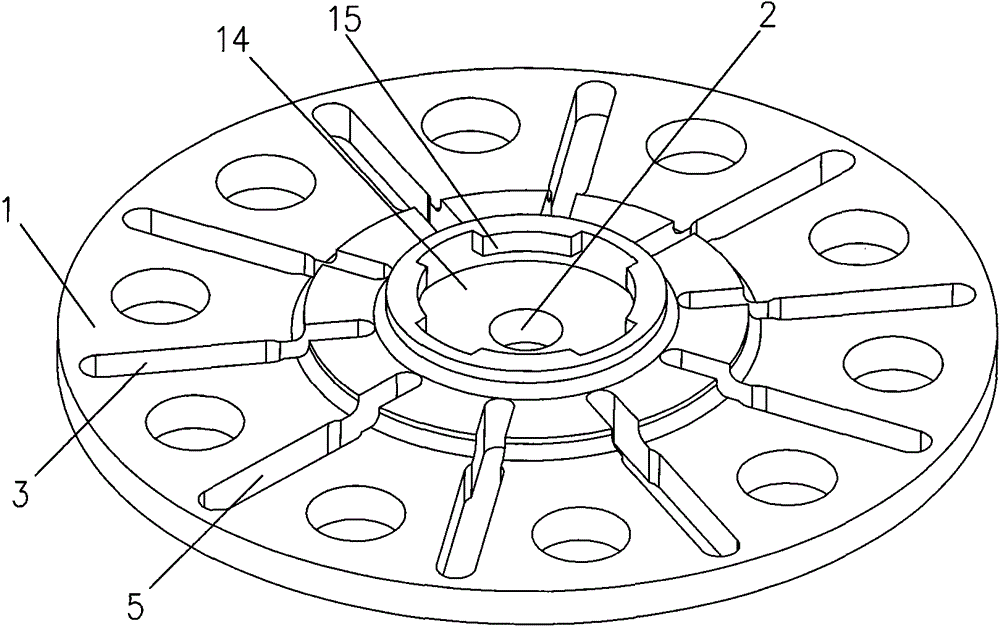

[0025] Such as figure 1 , figure 2 with Figure 4 As shown, the snap-type explosion-proof tire portable manual quick disassembly assembly tool of the present invention includes a push-pull disc 1 with a disc surface in the horizontal direction. The center of the push-pull disc 1 is provided with a central hole 2 in the vertical direction. The central hole 2 is used for wire The bar 18 passes through the push-pull plate 1 and extends downwards to the middle of the top bearing plate 4. The plate surface of the push-pull plate 1 is provided with 3-16 strip-shaped through slots 3 symmetrically along the radial direction of the central hole 2. The through groove 3 is convenient to adjust the position of the pull rod, so that the lower end of the pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com