A floor structure for a rail vehicle

A technology for rail vehicles and floors, applied in the field of rail vehicles, can solve problems such as inapplicability, and achieve the effects of delaying collapse, reducing overall height, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

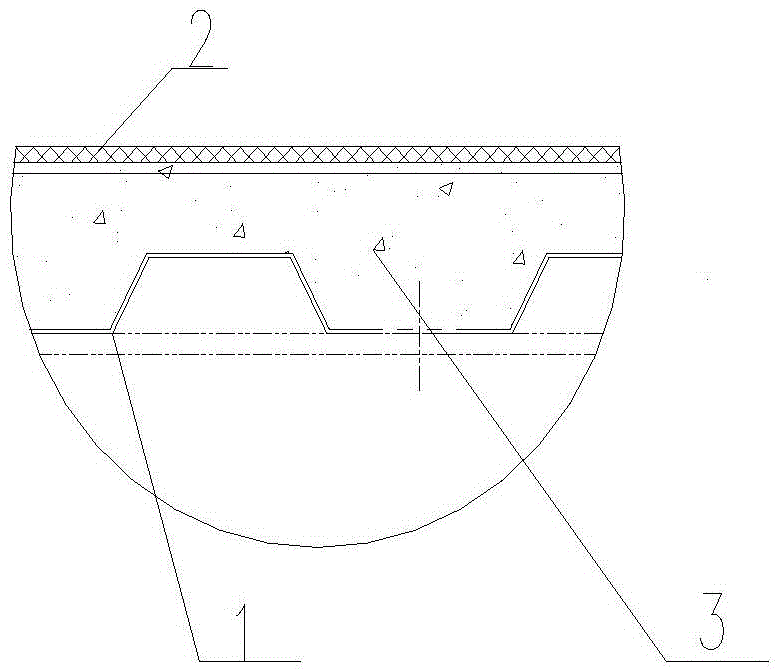

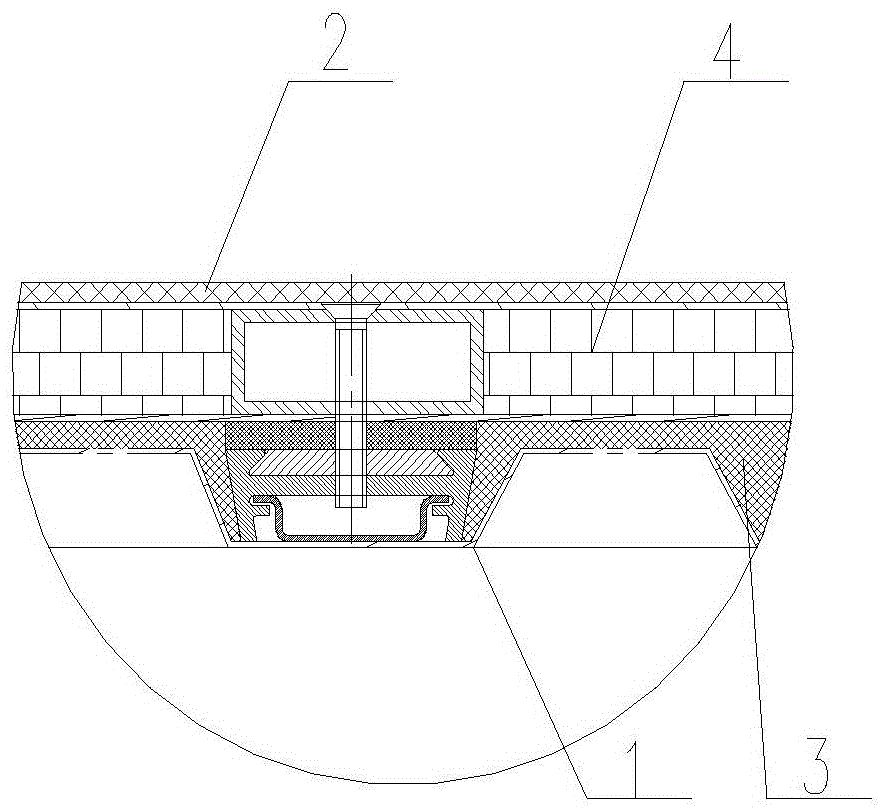

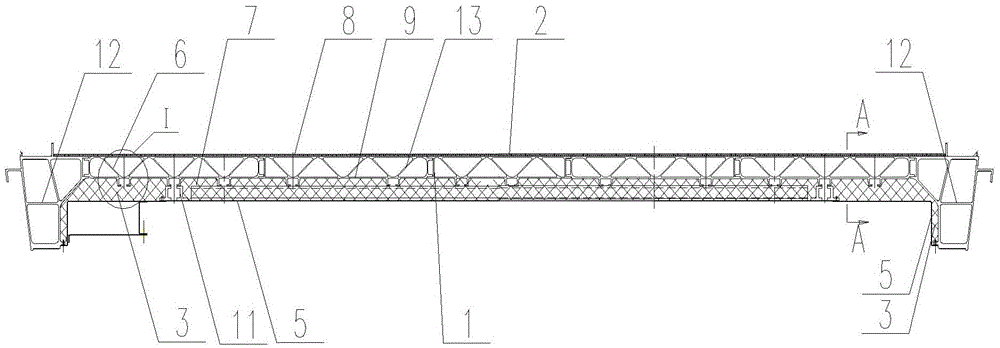

[0024] Such as Figure 3 to Figure 5 As shown, a floor structure of a rail vehicle includes a car body chassis structure 1 , a floor cloth 2 , a heat insulating material 3 and a metal plate 5 .

[0025] Wherein, the car body underframe structure 1 includes a hollow profile layer 6 on the upper floor and a suspension beam layer 7 on the lower floor, and the two sides of the car body underframe structure are also provided with underframe side beams 12. In urban rail vehicles, The hollow profile layer 6 generally adopts aluminum profiles. The hollow profile layer 6 includes an upper aluminum plate 8, a lower aluminum plate 9 and a middle reinforcing rib 13, and the hanging beam layer 7 includes a beam 10 and a longitudinal beam 11 for hanging equipment under the vehicle, and also includes a corbel (not shown in the figure). ) etc., the beam 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com