Filter-bag frame packaging tool

A frame and filter bag technology, applied in the field of filter bag frame packaging tools, can solve the problems of low reuse rate, different shapes, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

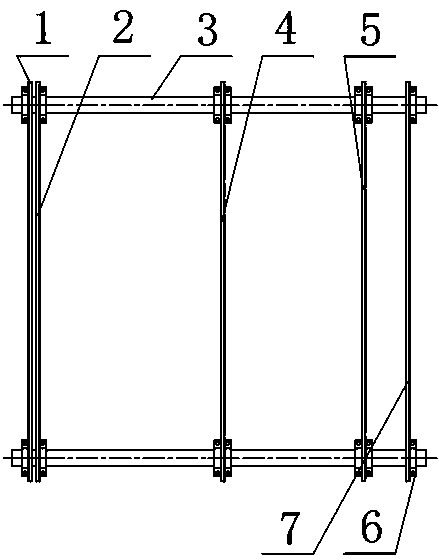

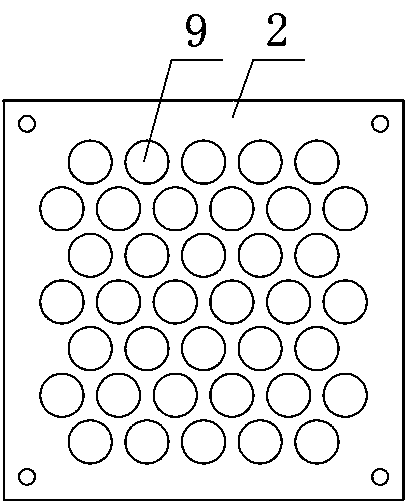

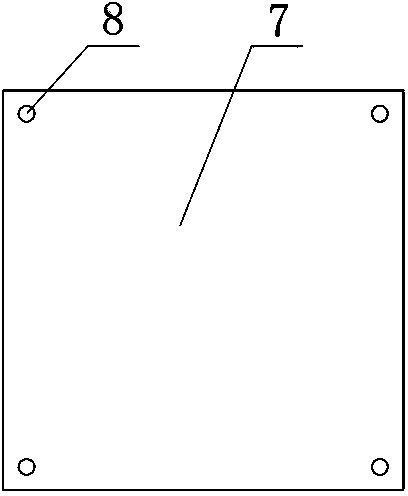

[0015] figure 1 Among them, a filter bag frame packaging tool, including a front guard plate 1, a front fixing plate 2, a middle fixing plate 4, a rear guard plate 7, a support tube 3 and a fastener 6. The structure of front guard plate 1 and rear guard plate 7 is identical, as image 3 As shown, the structure of the front fixed plate 2 and the middle fixed plate 4 is the same, as figure 2 shown. The front guard plate 1, the front fixed plate 2, the middle fixed plate 4 and the rear guard plate 7 are all provided with the same through hole 8, and the through hole 8 is matched with the support pipe 3. In this embodiment, the fasteners used are the same as the fastener 6 . The fixed plate 2 and the middle fixed plate 4 are evenly provided with a number of identical filter bag frame limiting holes 9 , with spacing between the limiting holes 9 . The through holes 8 of the front guard plate 1 and the rear guard plate 7 are respectively sleeved on the two ends of the support tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com