Two-position workpiece detecting mechanism capable of being rotated and lifted

A workpiece detection, two-station technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient activities, affecting work efficiency, increasing production costs, etc., to reduce production costs, improve work efficiency, and facilitate detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

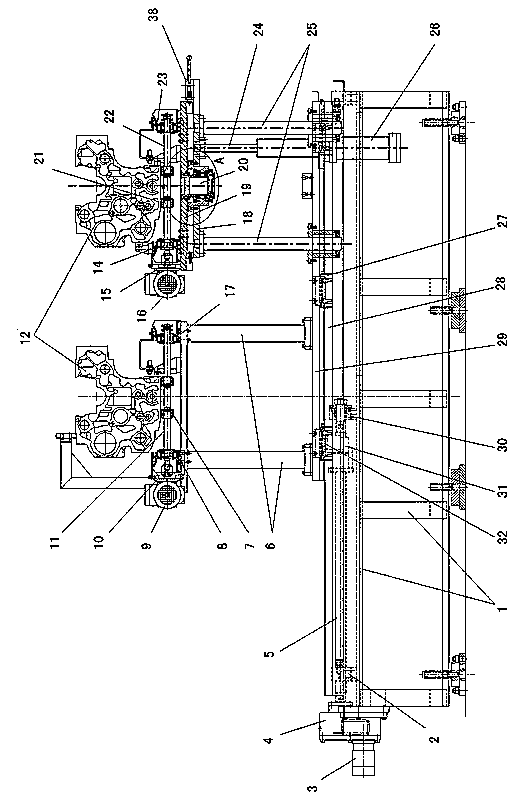

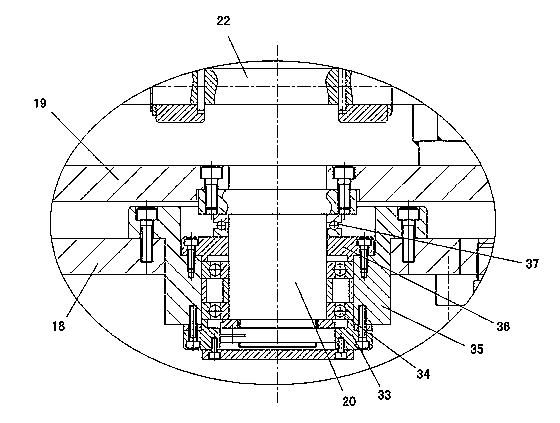

[0012] Such as figure 1 , 2 Shown: 1 is frame, is provided with the mobile plate 29 that connects driving device on frame 1, and mobile plate 29 can move relative to frame 1, and specific connection mode is as follows: slide block 27 is fixed below mobile plate 29 , the guide rail 28 matching the slider 27 is fixed on the frame 1, the connection mode of the ordinary guide rail slider can be selected, the dovetail sliding mode can also be selected, and the linear guide rail structure can also be selected, as long as the moving plate 29 passes through smoothly. Just move it above rack 1. The driving device that mobile plate 29 is connected is to support lead screw 5 by left support 2 and right support 30 on frame 1, is provided with bearing in each support, and the screw nut 31 that matches with lead screw 5 passes through screw nut The frame 32 is connected with the moving plate 29, that is, the upper end of the nut frame is fixedly connected with the moving plate 29 bolts, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com