Rubber plug transferring mechanism for filling machine

A filling machine and rubber stopper technology, which is used in food packaging machinery, rubber stopper transfer mechanism, and pharmaceutical fields, can solve the problems of increasing the difficulty of the operator's work, increasing the drug rejection rate, affecting the production efficiency, etc., and achieving a simple and compact structure and low cost. Inexpensive, avoids the effect of multiple adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

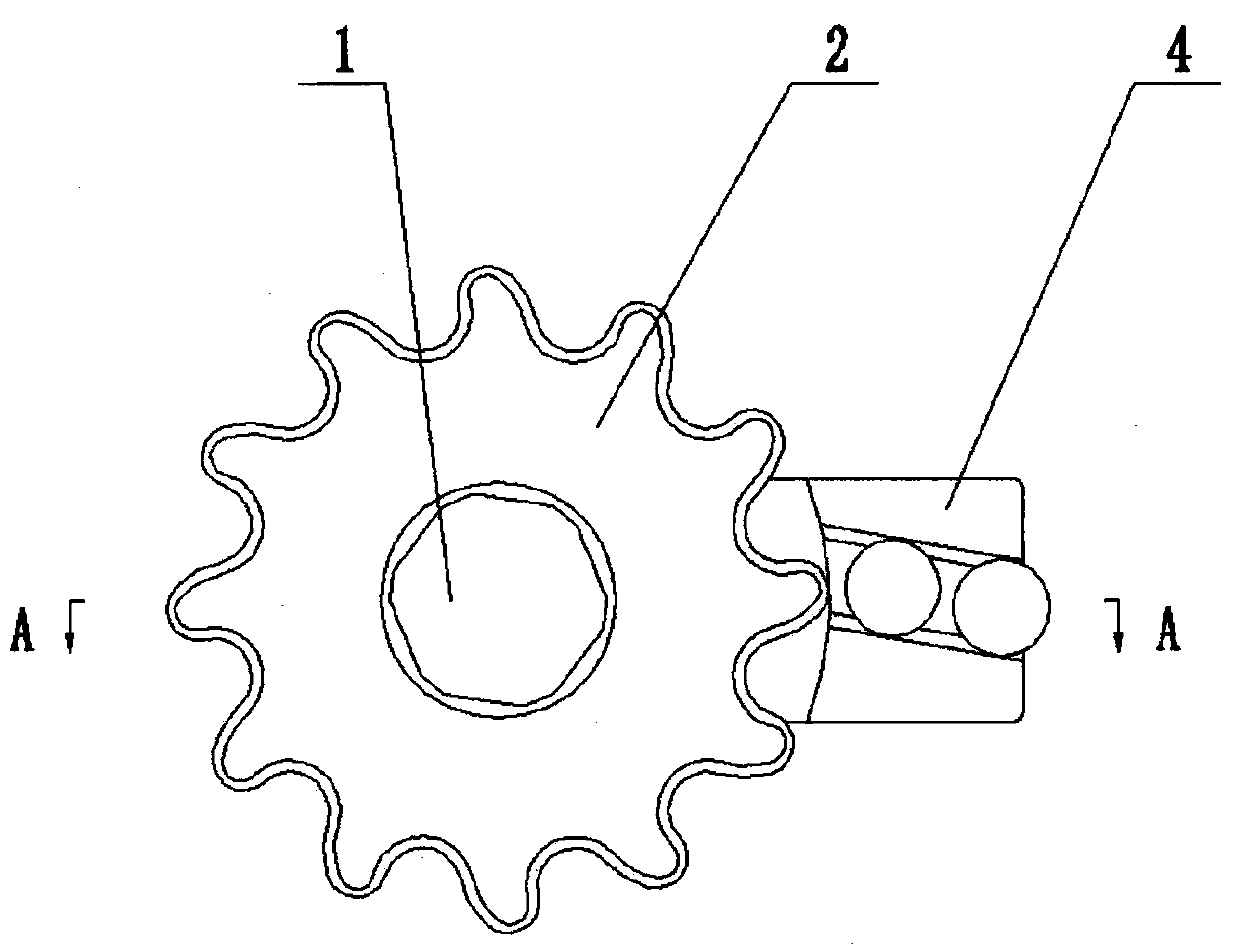

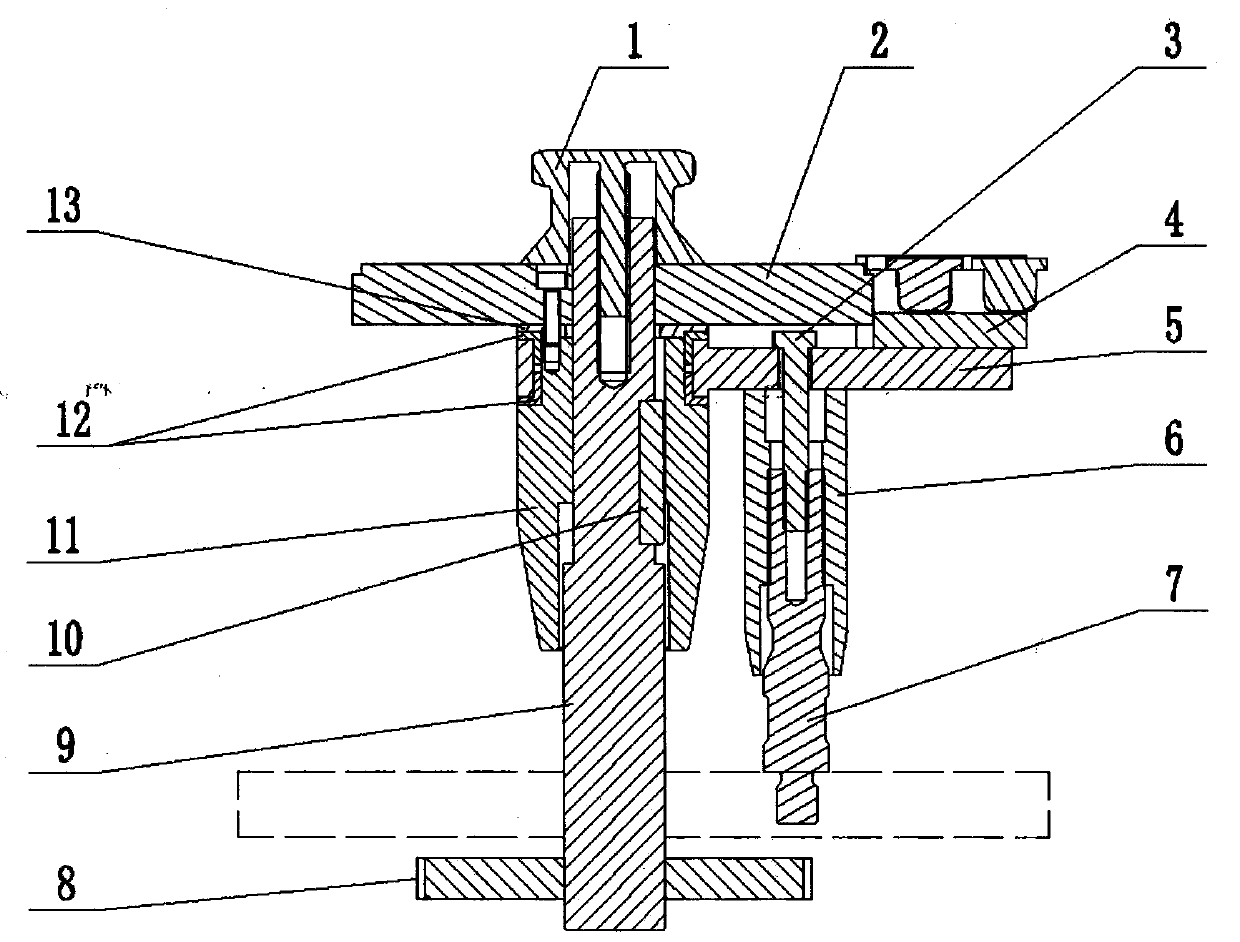

[0014] The invention is a rubber stopper transfer mechanism for a filling machine, such as figure 1 , figure 2 As shown, it includes the plug removal star wheel 2, the plug removal star wheel 2 passes through the plug removal star wheel rotation shaft 9, and the friction ring 13 is fixed on the sliding sleeve 11, and there is a friction ring 13 between the plug removal star wheel 2 and the sliding sleeve 11 Separated, a tightening knob 1 is installed on the top of the sliding sleeve 11, and the tightening knob 1 is screwed on the top of the star wheel rotating shaft 9 for plug removal, and the sliding sleeve 11 can rotate around the star wheel rotating shaft 9 driven by the gear 8, It can also slide up and down along it, and the sliding sleeve 11 is positioned through the flat key 10 between it and the star wheel rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com