Magnesite-dolomite ramming refractory taking castor oil as binding agent

A technology of castor oil and binder, which is applied in the field of magnesia dolomite refractory ramming materials, can solve the problems of narrow gaps, inability to use refractory bricks, complex structure, etc., and achieve easy use, high strength, and good thermal shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

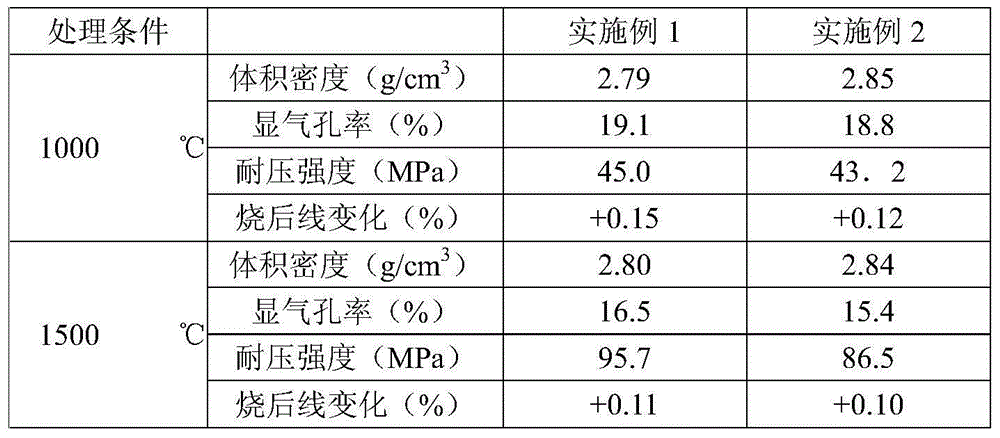

[0045] The components of each raw material are composed as follows by weight percentage: magnesia-calcium sand is made into three particle sizes of A, B, and C respectively, among which: 8≥A>3mm13%; 3≥B>1mm35%; 1≥C>0mm22%; industrial use Castor oil 7%; 98 fused magnesium 240 mesh: 25.5%; chrome green: 1%; 92 silica fume: 0.5%; fluorite powder 325 mesh: 2%; resin powder 4012 (thermosetting): 1%; Schedule 1.

[0046] This refractory ramming material is used in the stainless steel AOD furnace, at the edge of the spherical furnace bottom. Due to the erosion of refractory bricks at this position, the refractory ramming material will be exposed to the severe erosion of molten steel after several furnaces of smelting. This invention has high corrosion resistance and thermal shock resistance, and is easy to sinter to generate strength and can Effectively prevent molten steel from leaking.

Embodiment 2

[0048] The raw material components are composed as follows according to the weight ratio: magnesia-calcium sand is made into three particle sizes of A, B and C respectively, among which: 8≥A>3mm12%; 3≥B>1mm37%; 1≥C>0mm20%; Industrial castor oil 6%; 98 fused magnesium 240 mesh: 25.5%; chrome green: 2%; 92 silica fume: 0.5%; fluorite powder 325 mesh: 2%; resin powder 4012 (thermosetting): 1%; detection performance See attached table 1 for indicators.

[0049] This refractory ramming material is used in the stainless steel AOD furnace, at the bottom edge of the open hearth furnace. The depth of the bottom edge of the open hearth furnace is relatively large and the gap is small, and the construction conditions are relatively harsh. The invention has good construction performance and ensures construction quality. The smelting at this position will contact molten steel, and the present invention has easier sinterability in the baking stage before receiving molten steel, which can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com