Cementing material for durable colored pavement and preparation method thereof

A cementitious material, durable technology, applied in the direction of roads, roads, coagulation pavement paved on site, etc., can solve the problem of difficult to meet road rutting resistance, water damage resistance, affecting the durability of color pavement, failure of color pavement pavement, etc. problem, to achieve the effect of stable character, long life and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Implementation and application of colored pavement restraint layer (red)

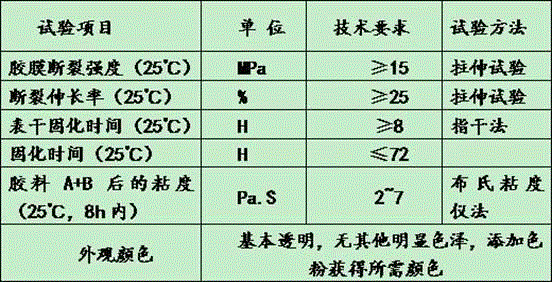

[0023] Prepare epoxy resin cementing material, the specific components and proportions are as follows: Component A: 72 parts of bisphenol A epoxy resin (E-51), 20 parts of reactive diluent-butyl glycidyl ether, toughening agent-poly 15 parts of propylene glycol diglycidyl ether, 3 parts of silane coupling agent γ-glycidoxypropyltrimethoxysilane, antioxidant 4,4'-thiobis(3-methyl-6-tert-butyl ) 0.5 part of phenol and 0.5 part of ultraviolet absorber 2-hydroxy-4-methoxybenzophenone. After the above ingredients are prepared, place them in the same container at room temperature and mix and stir for 8-10 minutes until they are uniform, and they are sealed and packed in barrels. ; The number of parts by weight;

[0024] Component B: 20 parts of A-type curing agent metaxylylenediamine, 10 parts of tough curing agent polyetheramine, 23 parts of B-type curing agent N-aminoethylpiperazine, accelerator 2,4,6-...

Embodiment 2

[0031] The implementation and application of the colored pavement concrete surface layer (red), that is, the colored pavement concrete surface layer is laid on the EC restrained bottom layer in Example 1.

[0032] First, prepare the cementing material for the concrete surface. The specific components and proportions are as follows: component A: 75 parts of bisphenol A epoxy resin (E-51), 18 parts of active diluent butyl glycidyl ether, toughening 10 parts of polypropylene glycol diglycidyl ether, 3 parts of silane coupling agent γ-glycidoxypropyltrimethoxysilane, antioxidant 4,4'-thiobis(3-methyl-6-tert Butyl) 0.5 part of phenol, 1 part of ultraviolet absorber 2-hydroxy-4-methoxybenzophenone. After the above-mentioned components are configured, place them in the same container at room temperature and mix and stir for 8-10 minutes until they are uniform. The barrel is sealed and packaged, and the number of parts is calculated by weight;

[0033] Component B: 19 parts of A type curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com