Preparation method of delustering agent for UV (ultraviolet) curing coating

A technology for curing coatings and matting agents, applied in coatings and other directions, can solve the problems that matting agents cannot meet the needs of UV curing coatings, and achieve excellent matting performance, small viscosity changes, and low viscosity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The method for preparing a matting agent for UV curing coatings of the present invention includes:

[0033] (1) Raw materials:

[0034] Raw material A: an inorganic acid solution with a mass ratio of 5-40%; preferably an inorganic acid solution with a mass ratio of 10-15%; among them, the inorganic acid can be sulfuric acid or hydrochloric acid, or other inorganic acids that can achieve the effects of the present invention, such as Nitric acid etc.

[0035] Raw material B: an alkali metal inorganic silicate solution with a mass ratio of 5-50%; preferably an alkali metal inorganic silicate solution with a mass ratio of 15-20%, wherein the alkali metal inorganic silicate can be sodium silicate, Or potassium silicate, potassium sodium silicate, lithium silicate and quaternary ammonium silicate can obtain products with the same effect.

[0036] Raw material C: the wax emulsion required for the final product; wherein, the wax emulsion includes any conventional wax dispersed in wate...

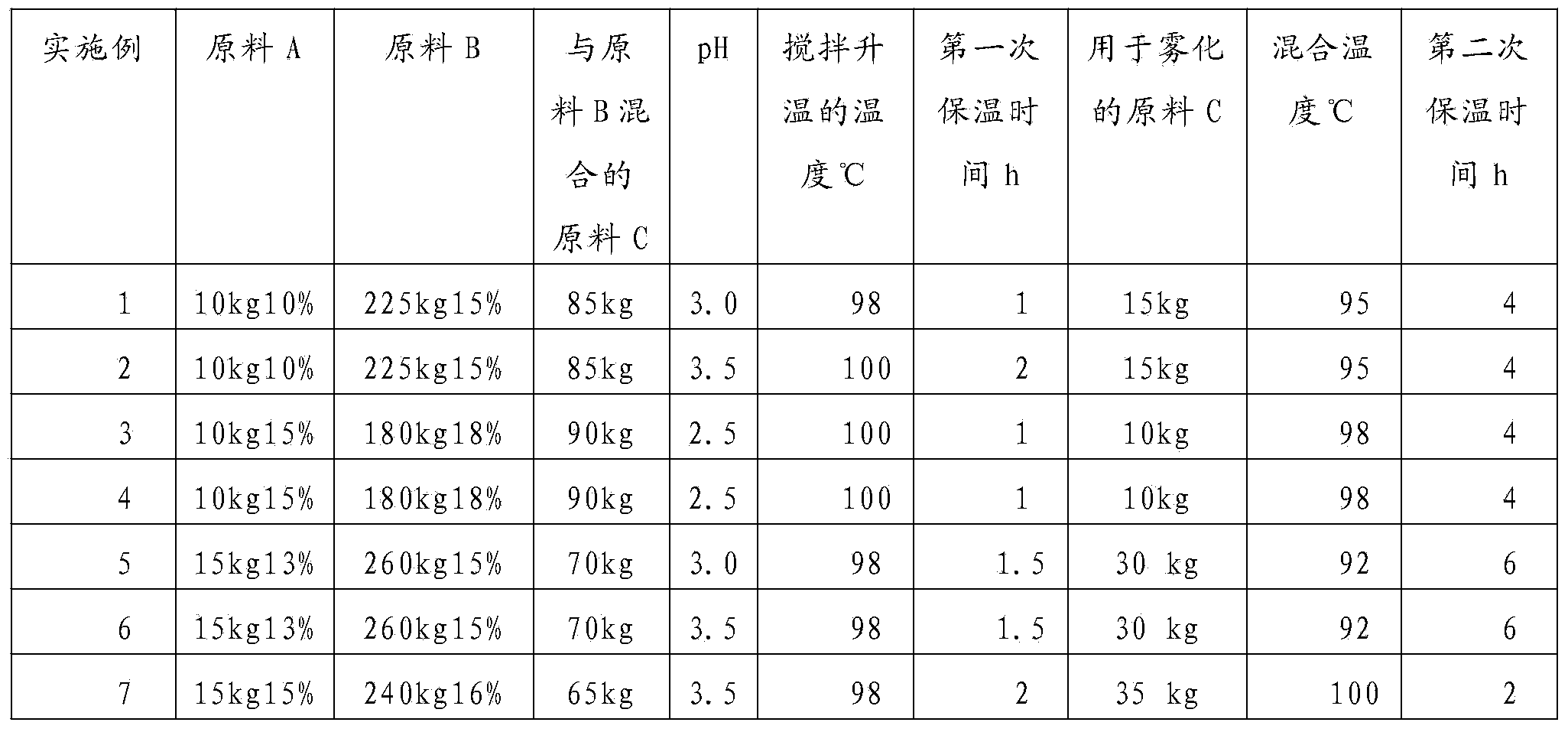

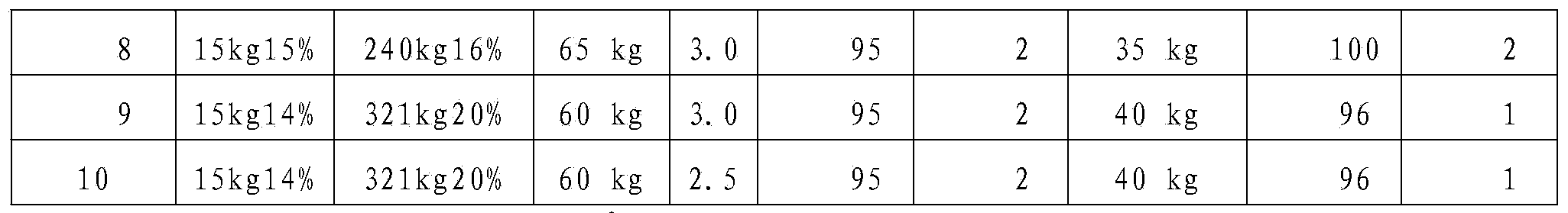

Embodiment 1-10

[0049] Add raw material A (take sulfuric acid as an example) into the reaction vessel, keep stirring, heat the raw material B (take sodium silicate as an example), and control the temperature at 75~80℃. Use a CN102476802A mixer and 60-90% Raw material C is mixed and added to the reaction vessel, the pH value of the reaction material is controlled at 2.5-3.5; the stirring is heated to 95-100°C, and the temperature is kept for 1-2 hours; the crude product is obtained after washing and drying; the 10- 40% of the raw material C is atomized, thoroughly mixed with the crude product at 92-100°C and kept for 1-6 hours, and ultrafinely pulverized to an average particle size of 3-5μm. By changing reaction conditions, etc., products of different examples were obtained.

[0050]

[0051]

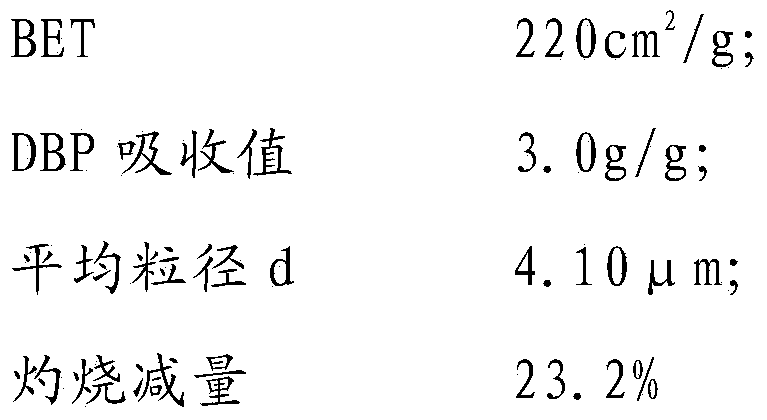

[0052] Test data BET100~250cm 2 / g; DBP absorption value 0.4~2.2g / g; ignition loss 22~24%.

[0053] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com