Production method of high torque spinning yarn

A production method and yarn spinning technology are applied in the field of high-torque spinning yarn production to achieve the effects of reducing yarn hairiness, increasing strength and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

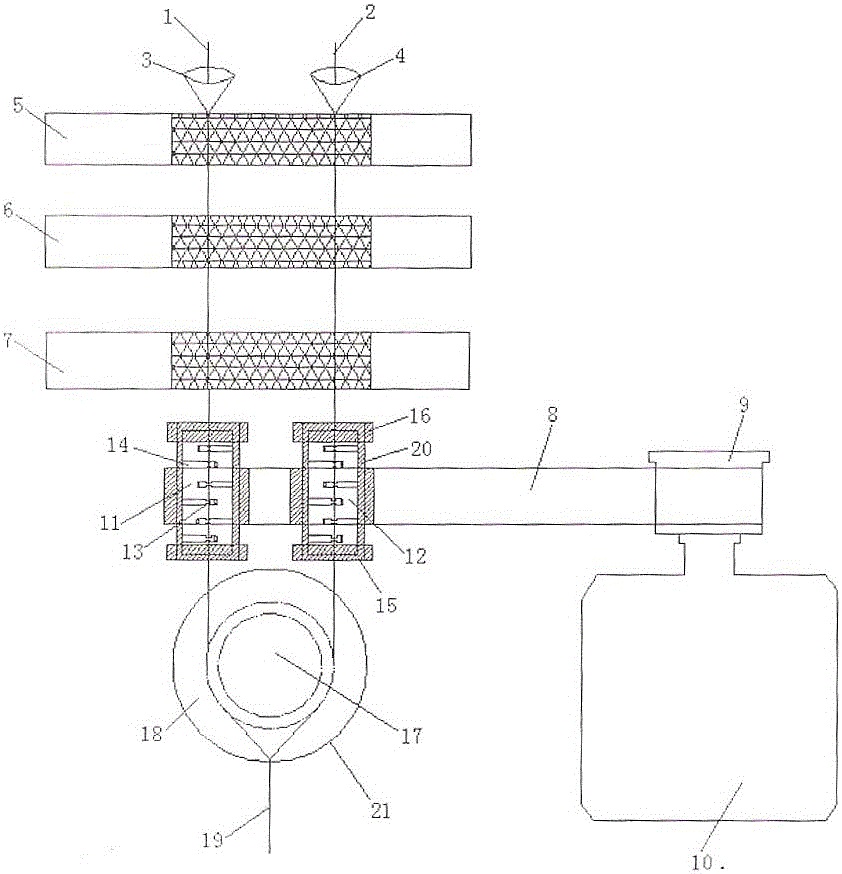

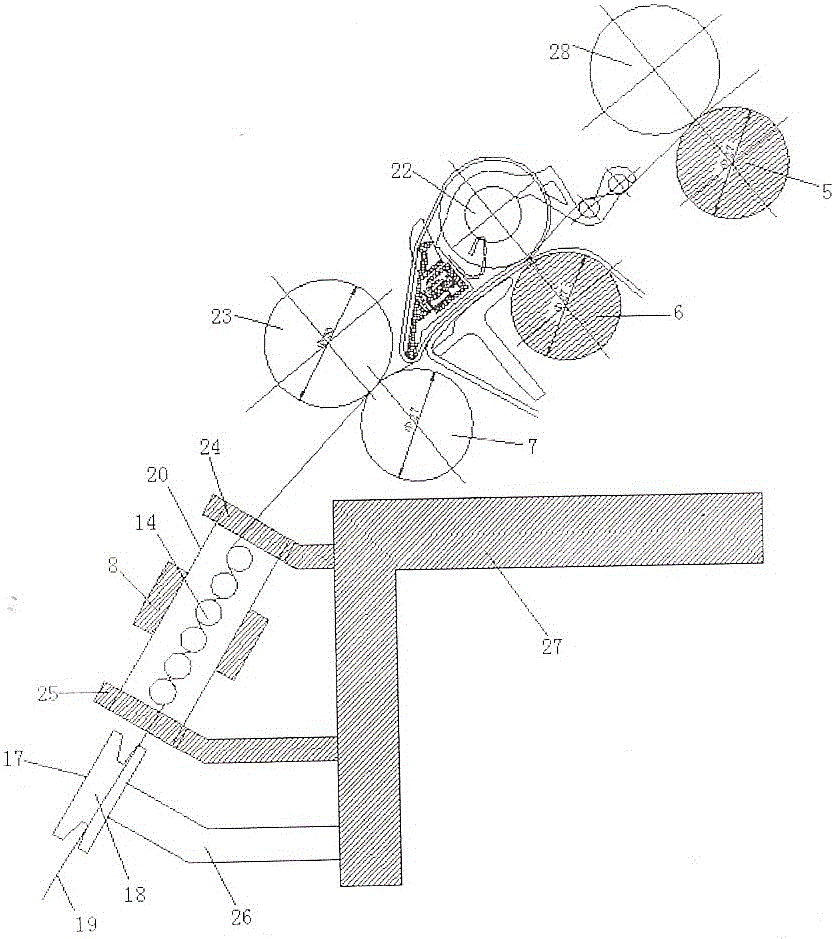

Image

Examples

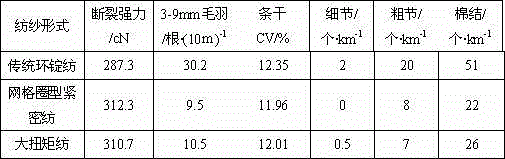

Embodiment 1

[0023] Example 1: Take the device installed on the FA506 ring spinning frame to spin pure cotton combed 14.6tex yarn as an example, wherein the raw cotton is 100% Xinjiang long-staple cotton.

[0024] The parameters of each process in the production process are as follows:

[0025] (1) Blowing and carding process: the nep growth rate of banquet cotton is 82% higher than that of raw cotton. The speed of the sawtooth roller main cleaning roller is 720r / min, the speed of the opening roller of the feeding box is 900r / min, the speed of the cylinder of the carding machine is 425r / min, the ratio of the linear speed of the cylinder to the licker-in roller is 2.7, and the speed of the cover plate is 280m / min , the distance between the face plate and the licker-in roller is 0.75mm, the distance between the cylinder and the doffer is 0.1mm, the distance between the cylinder and the cover plate is 0.21, 0.175, 0.18, 0.18, 0.2mm, the distance between the cylinder and the rear fixed cover p...

Embodiment 2

[0033] Example 2: Take the installation of this device on the FA506 ring spinning frame to spin pure cotton combed 9.7ex yarn as an example, wherein the raw cotton is 100% Xinjiang long-staple cotton.

[0034] The parameters of each process in the production process are as follows:

[0035] (1) Blowing and carding process: the nep growth rate of banquet cotton is 80% higher than that of raw cotton, the speed of the catching machine is 1180r / min, the cotton opening adopts a double-axis flow opener, the speed of the beating is 490r / min, and the cleaning machine The speed of the sawtooth roller main cleaning roller is 690r / min, the speed of the opening roller of the feeding box is 840r / min, the speed of the cylinder of the carding machine is 395r / min, the ratio of the linear speed of the cylinder to the licker-in roller is 2.4, and the speed of the cover plate is 265m / min , the distance between the face plate and the licker-in roller is 0.70mm, the distance between the cylinder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com