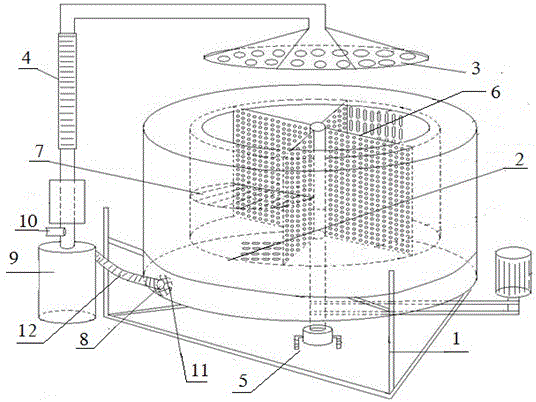

Core supplementation and infiltration dehydration device

A dehydration device and water outlet technology, which can be used in the configuration of equipment for processing textile materials, spraying/jetting textile materials, removing liquid/gas/vapor by centrifugal force, etc., which can solve the problems of blocked pipes, ineffectiveness, and large volume , to avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0014] A kind of core type nourishing infiltration and dehydration device, comprising a fuselage triangular support 1, a drum 2 is provided on the support 1, the drum 2 can be closed with a water outlet nozzle 3, the water outlet nozzle 3 is arranged on a connecting rod, and the connecting rod is provided with a Lifting telescopic device 4. The lower end of the shaft center of the drum 2 is provided with a shock absorber 5 to prevent the drum 2 from vibrating too much, and the upper end of the shaft center is evenly provided with a partition plate 6. The wall of the inner tank, the bottom of the cylinder and the partition plate are uniformly provided with water outlets to discharge the liquid. There are four partition plates 6, and the internal space of the drum 2 is divided into four chambers of the same size. 2. A fabric fixing plate 7 is detachably arranged inside. The plane direction of the fabric fixing plate 7 is perpendicular to the plane of the partition plate. The fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com