Rotary lily splitting device

A rotary, split-lobe technology, applied in application, food processing, food science and other directions, can solve the problems of unfavorable development of the lily industry, heavy workload and high cost, and achieve the goal of reducing human labor, improving work efficiency and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

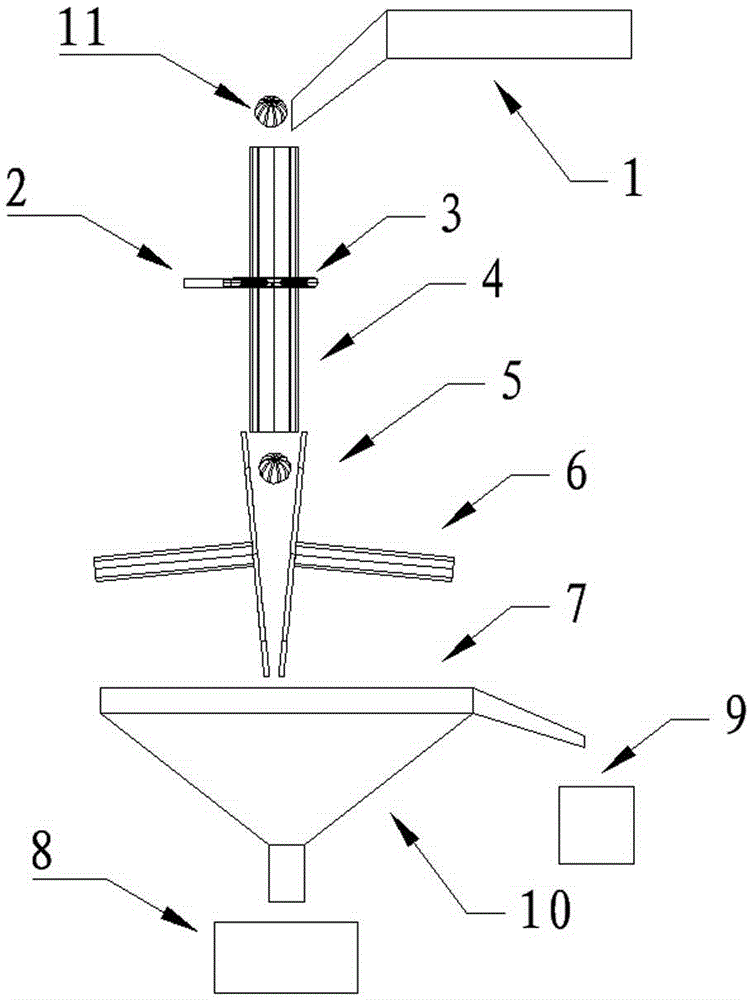

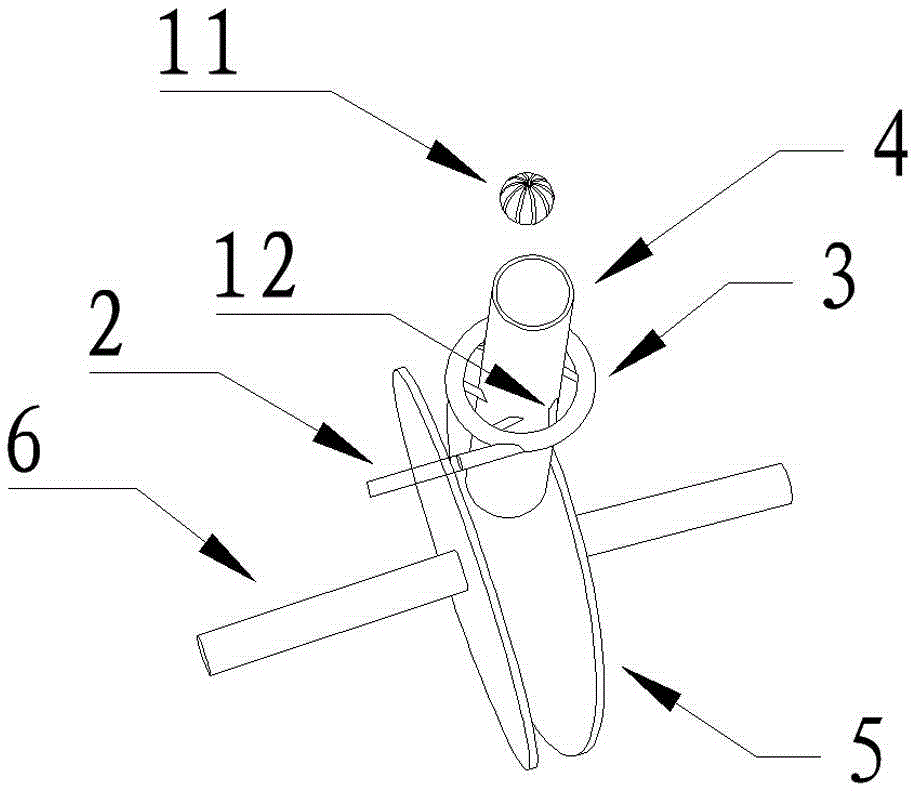

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0023] Such as figure 1 and figure 2 The rotary lily splitting device shown includes two soft turntables 5, the turntables 5 are oppositely arranged but rotate in opposite directions, and the distance between the turntables 5 is adjustable between 1-10 cm.

[0024] The top of the soft turntable 5 is provided with a vertical cyclone pipe 4, and the cyclone pipe 4 is provided with a jet pipe 12 which enters tangentially.

[0025] There are 1-10 jet pipes, which are jointly connected to an air guide ring 3, and the air guide ring 3 is provided with a general air inlet 2.

[0026] A vibrating feeder 1 is arranged above the soft turntable 5 or the cyclone tube 4, which facilitates the transportation of lily bulbs and realizes continuous production.

[0027] The soft turntable 5 is connected with a disk shaft 6, and the disk shaft 6 is connected with power to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com