Rotary Garlic Separator

A rotary garlic technology is applied in the field of rotary garlic splitting devices, which can solve the problems of unfavorable development of the garlic industry, complex structure, inability to meet the garlic industry, etc., and achieve the effects of simple and reliable machine structure and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

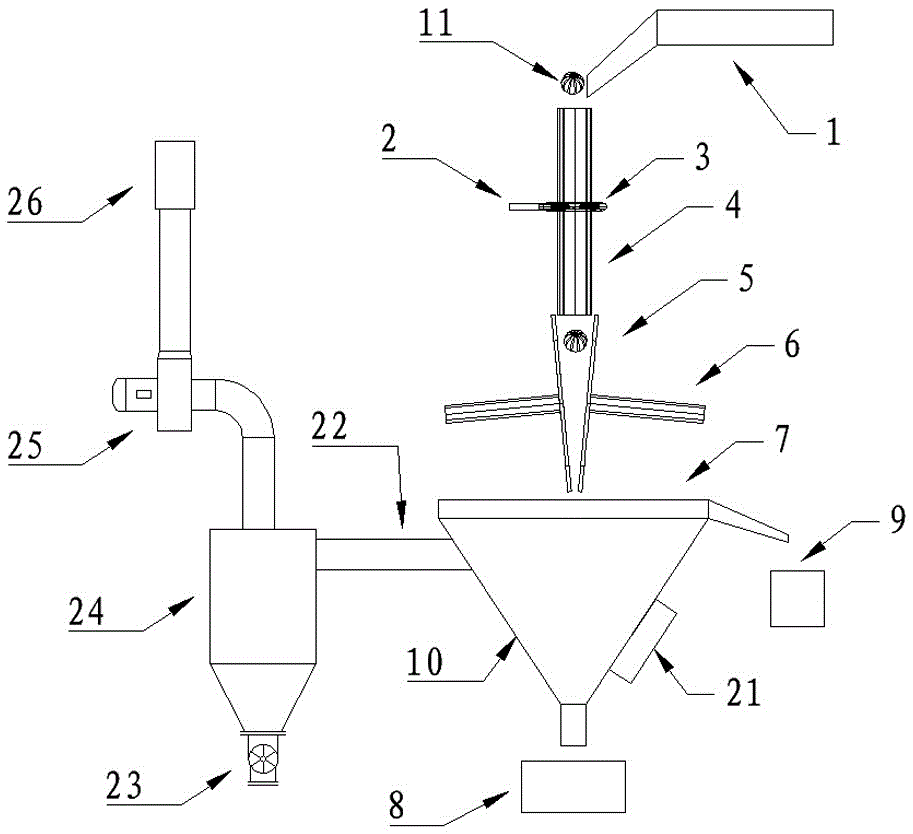

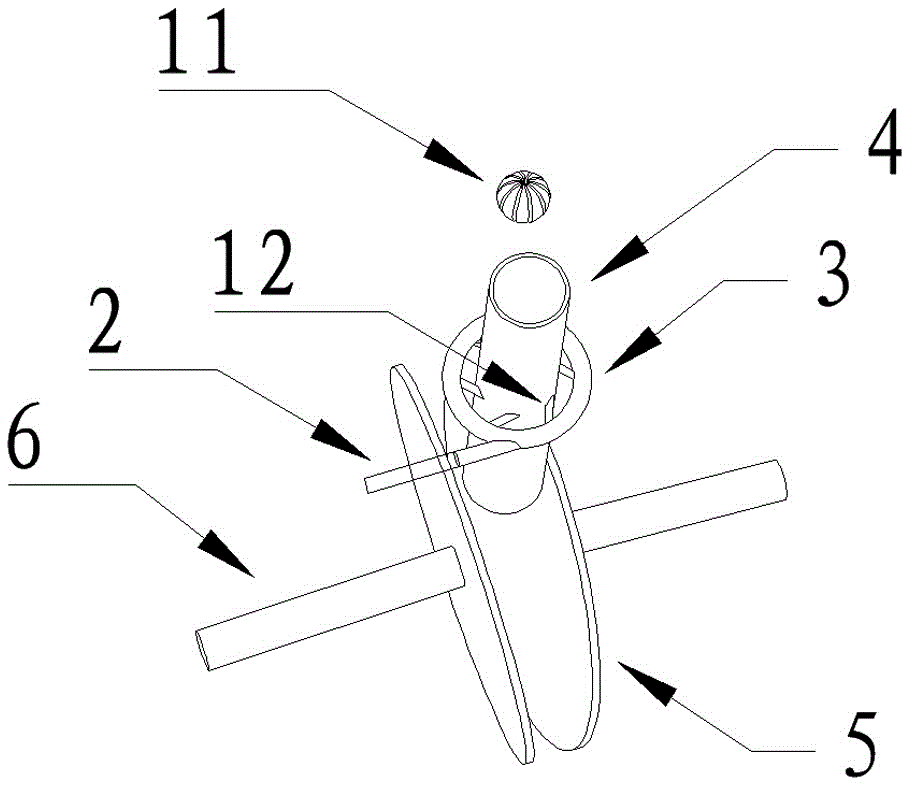

[0023] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0024] Such as figure 1 with figure 2 The shown rotary garlic splitting device comprises two soft turntables 5, the turntables 5 are oppositely arranged but rotate in opposite directions, and the distance between the turntables 5 is adjustable between 1-15 centimeters; the soft turntable 5 is provided with vibration Sorting machine 7, the output end of vibrating sorting machine 7 is provided with garlic bulb hopper 9, and the feeding end of vibrating sorting machine 7 is a cone bucket 10 structure, and the bottom of the cone bucket 10 is provided with garlic clove bucket 8; The connecting pipe 22 is connected tangentially to the cyclone separator 24 , the central pipe of the cyclone separator is connected to the exhaust fan 25 , and the bottom of the cyclone separator is connected to the air-closing discharger 23 ; the cone bucket 10 is provided with an air inlet 21 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com