Directly driven brushless permanent-magnet motor with external rotor for washer

A permanent magnet brushless and external rotor technology, which is applied to electromechanical devices, synchronous motors with stationary armatures and rotating magnets, electrical components, etc., can solve the problems of stepless speed regulation, poor reliability, and heavy weight , to achieve the effects of improving work efficiency, improving reliability, and hardening mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

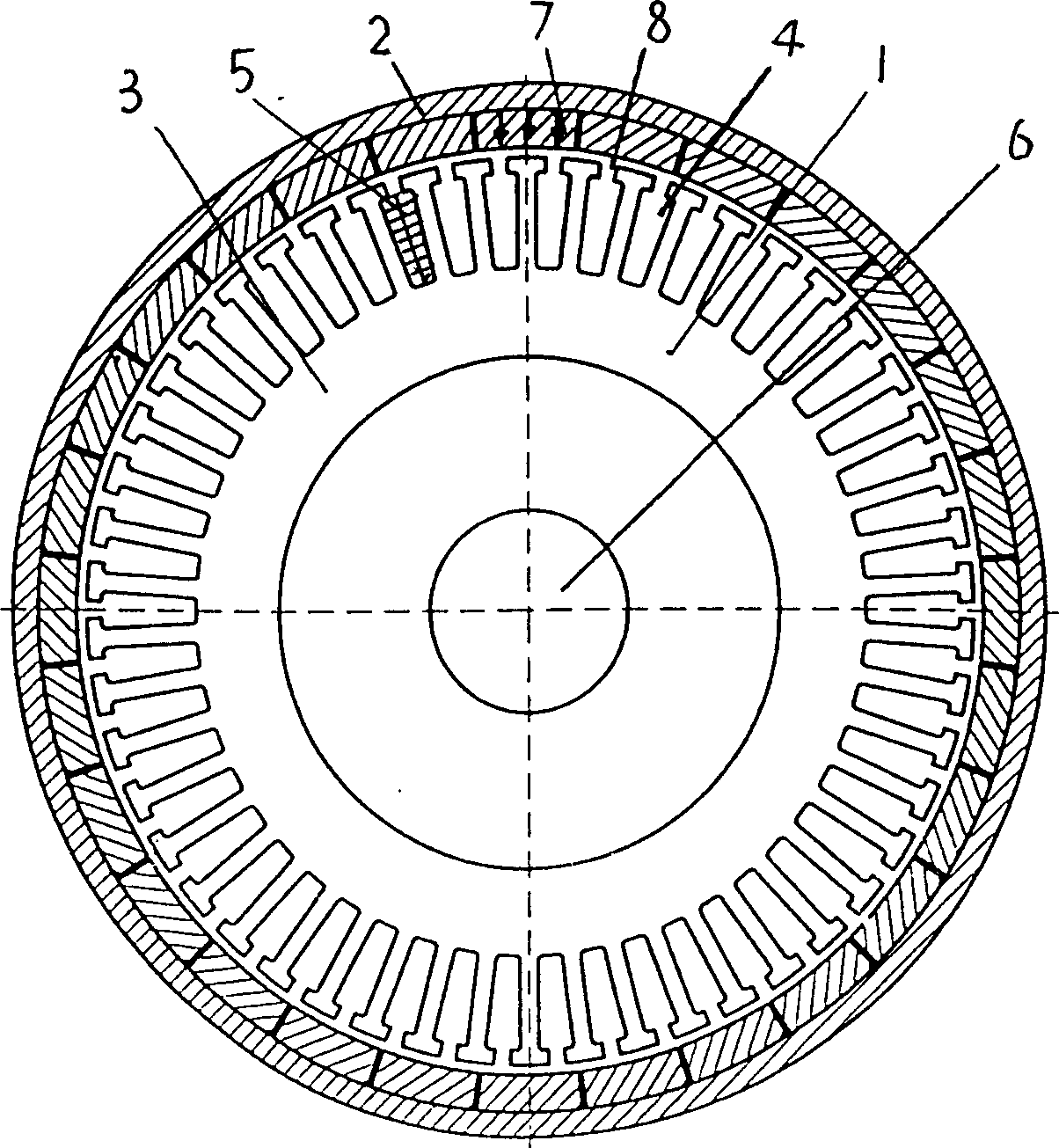

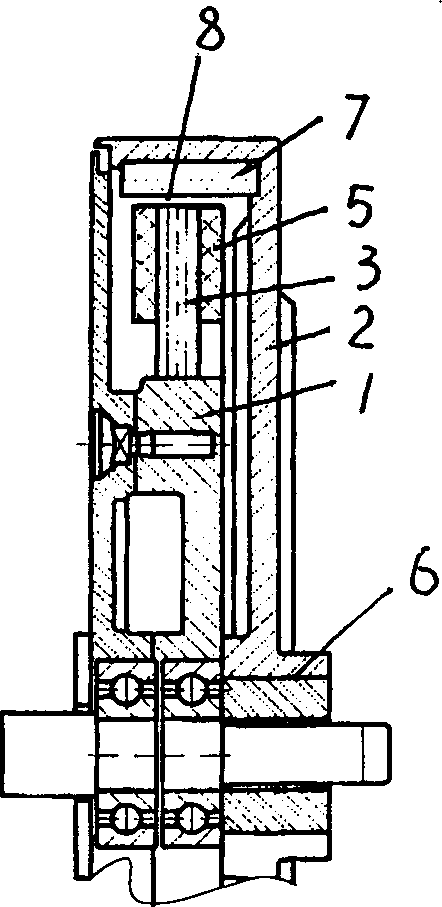

[0029] Example: such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, a direct-drive outer rotor permanent magnet brushless washing machine motor includes an inner stator [1] and an outer rotor [2], the inner stator [1] includes a stator yoke [3], on the stator yoke [3] It is equipped with a stator slot [4], and a stator winding [5] is arranged in the stator slot [4]. The outer rotor [2] is concave, and the end face is provided with a shaft hole [6]. A permanent magnet pole [7] is fixed on the inner wall of the circumference, and a radial air gap [8] is set between the inner stator [1] and the outer rotor [2].

[0030] In the future, the connection between the motor and the washing drum will be as follows: the outer rotor [2] of the motor is fixed on a Y-shaped outer aluminum bracket, the washing drum is rigidly connected with another Y-shaped inner aluminum bracket, and the outer rotor shaft hole [6] is inlaid with Spline groove, the two brackets are connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com