Magnetic rotating shaft

A magnetic suction type, rotating shaft technology, applied in pivot connection, instruments, electrical digital data processing, etc., can solve problems such as unsightly appearance, poor compatibility between notebook base and screen connection, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

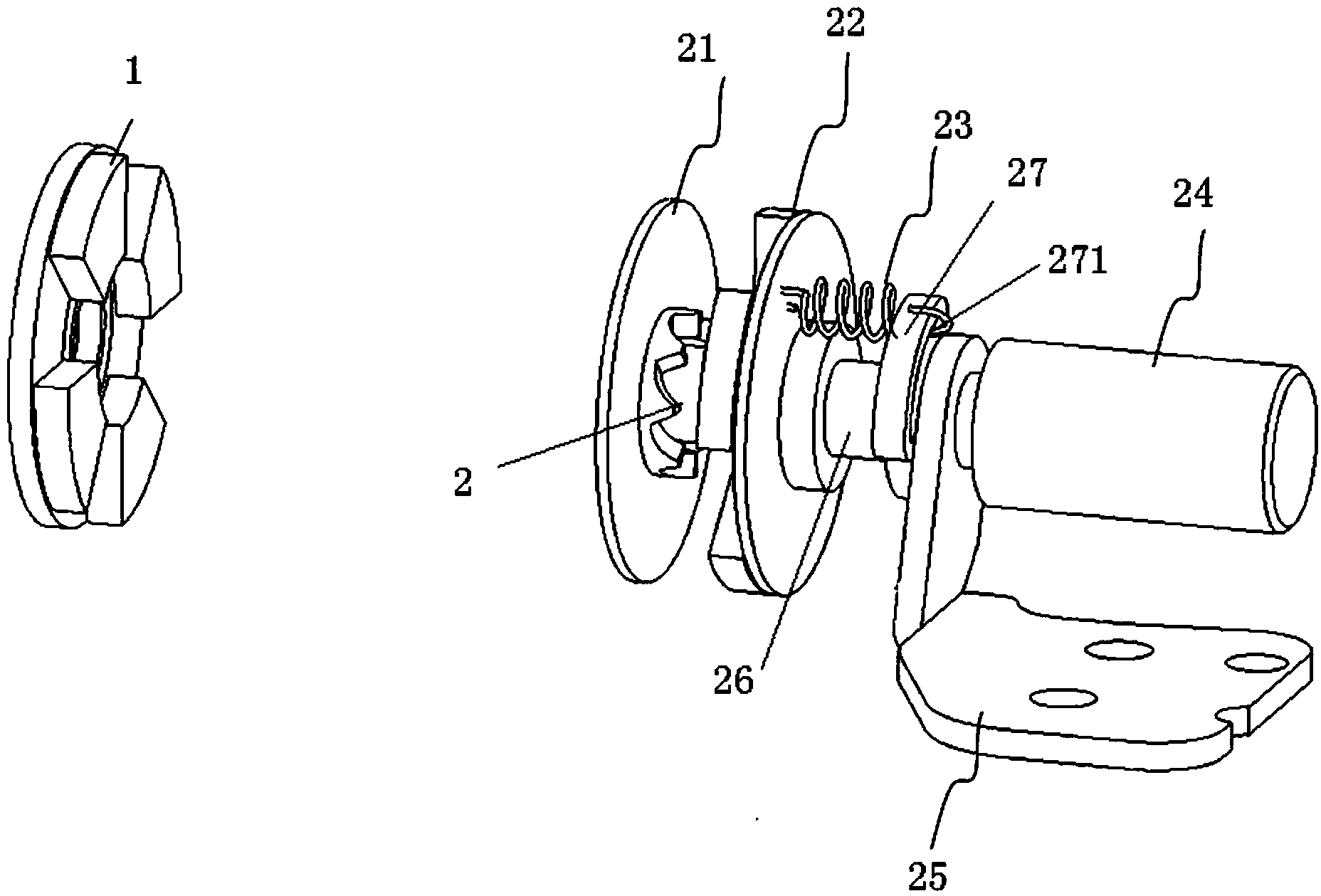

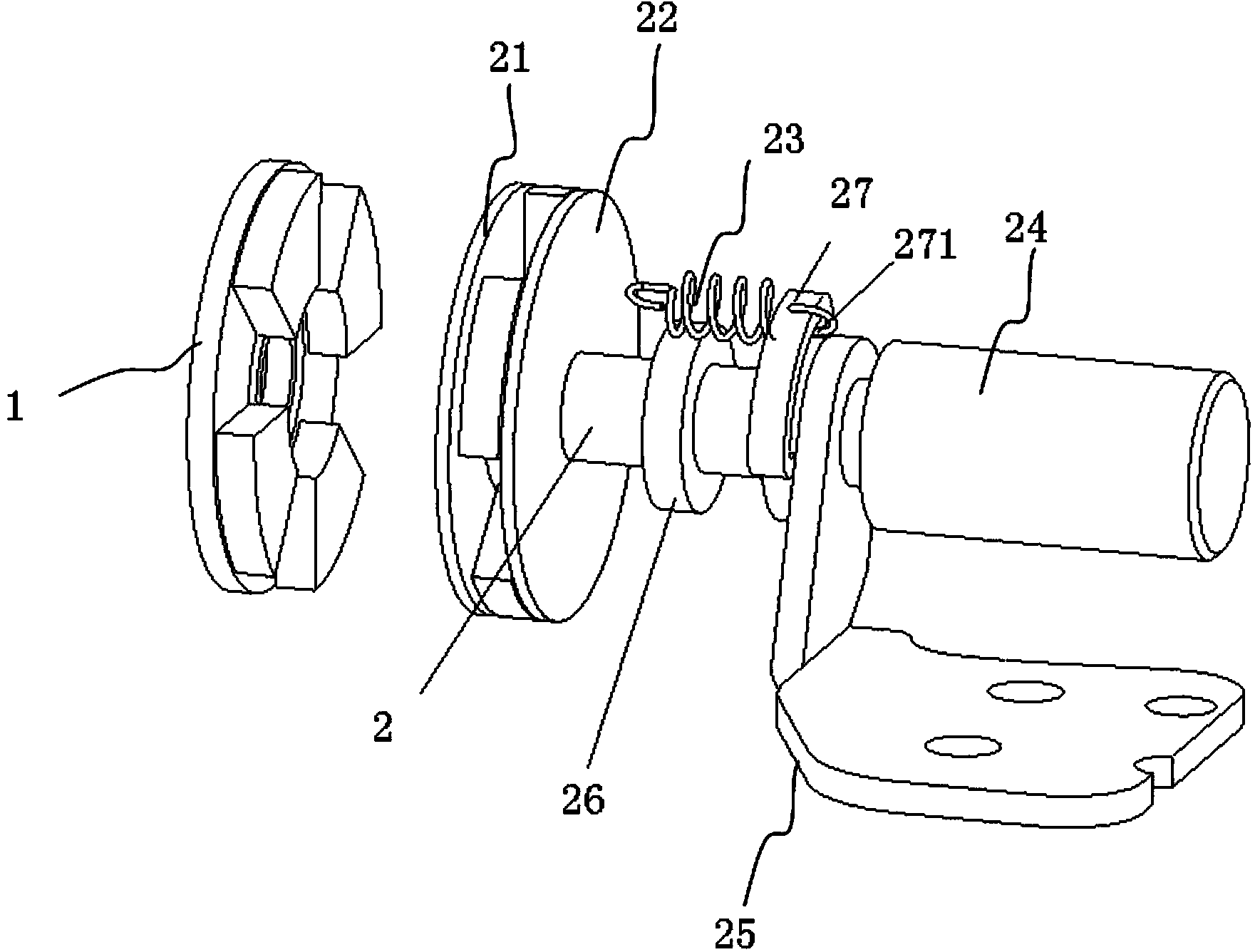

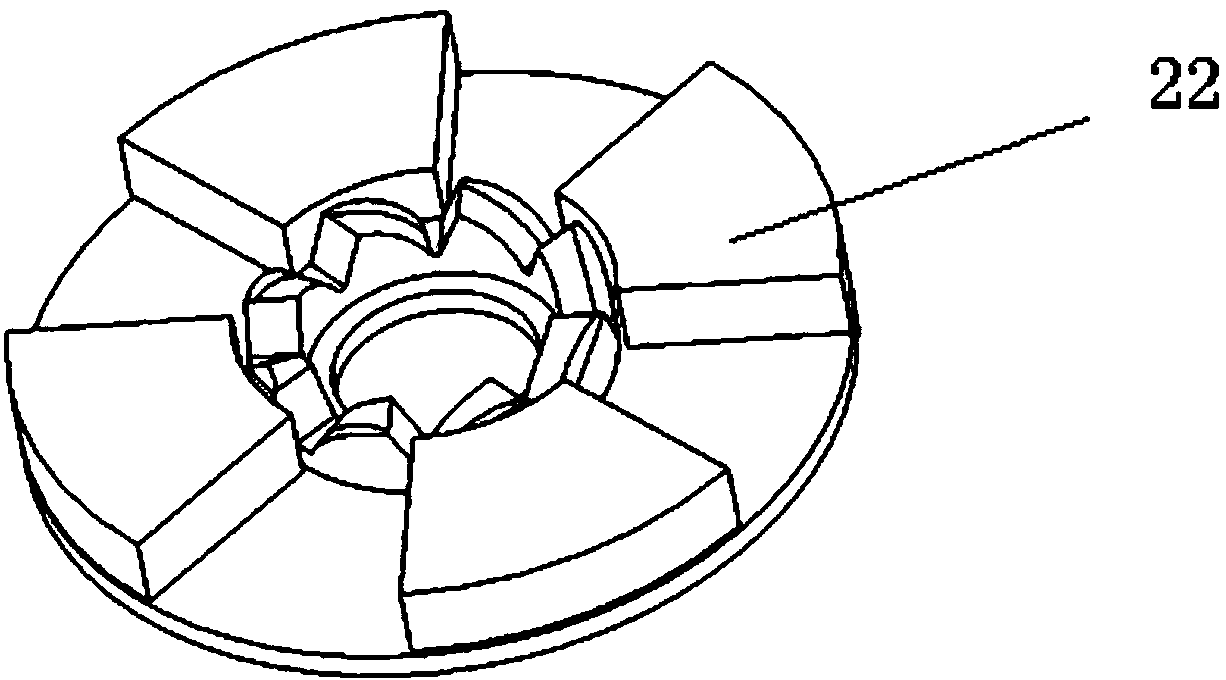

[0012] Such as figure 1 As shown, the magnetic suction type rotating shaft according to an embodiment of the present invention includes a first magnetic ring part 1 and a rotating shaft part 2, and the rotating shaft part 2 includes an engaging shaft 26 (such as Figure 4 As shown), the engaging shaft 26 includes a proximal end close to the magnetic ring part 1 and a distal end away from the magnetic ring part 1 . A radially expanding disk portion 21 is provided at the proximal end of the engaging shaft 26 , and a damper 24 is provided at the distal end to cooperate with the engaging shaft 26 to prevent the engaging shaft from pivoting. An arc groove portion 27 fixedly connected with the engaging shaft 26 is provided between the damper 24 and the disk portion 21 . Between the arc groove portion 27 and the disk portion 21, a second magnetic ring 22 (such as image 3 shown), wherein the second magnetic ring is set to have a magnetic field opposite to that of the first magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com