Transmission and speed governing device of food processing machinery

A technology for food processing and speed control devices, which is applied in transmission control, mechanical equipment, components with teeth, etc., can solve problems such as increased manufacturing costs, inconvenient operation, and many parts, etc. Simple, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

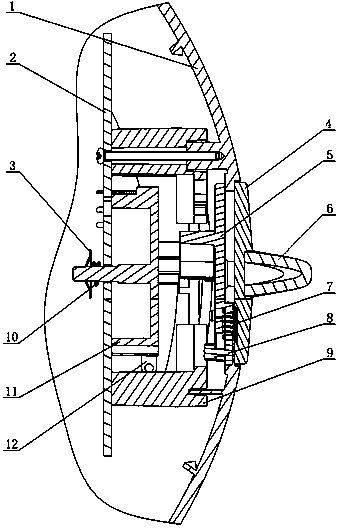

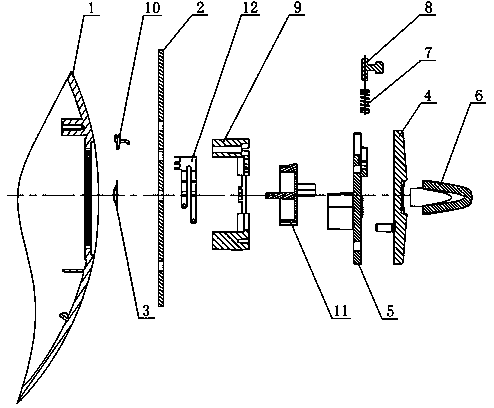

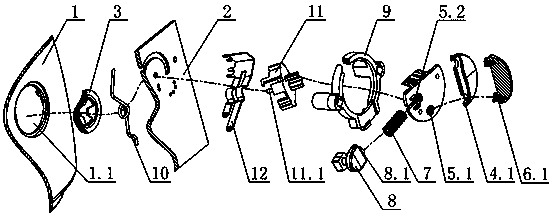

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0017] see Figure 1-Figure 3 , the food processing machine, including opening a main body 1 and a control panel 2 with mounting holes 1.1, the main body 1 is provided with a knob bracket 9 corresponding to the control panel 2, and the control panel 2 and the knob bracket 9 are fixed on the main body 1 by screws. The main body 1 is provided with a stepless speed regulation mechanism, so that the speed can be adjusted from zero speed to the highest speed, and then adjusted from the highest speed to zero speed. In this process, the stepless speed regulation is realized, so as to obtain the speed and speed required by the user. Accelerate instantly. The stepless speed regulation mechanism includes a start-stop key 4, on which a speed adjustment key 6 is arranged, and the speed adjustment key 6 and the start-stop key 4 are installed on the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com