Pneumatic silicone oil fan clutch capable of automatically adjusting rotating speed

An automatic adjustment and clutch technology, applied in the field of clutches, can solve the problems of advance and control lag, and achieve the effect of improving responsiveness, precise control, and improving precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

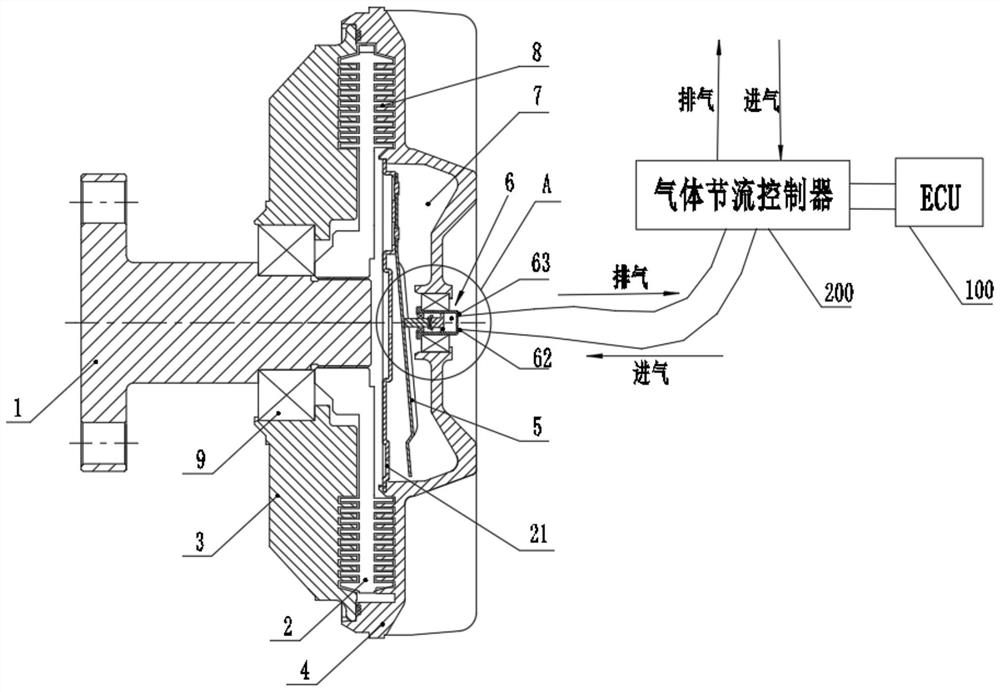

[0025] Embodiment: a kind of silicon oil fan clutch of pneumatic automatic speed adjustment, such as figure 1 and figure 2 As shown, the clutch includes a drive shaft 1, a drive plate 2, a housing 3, a cover 4, a driven plate 5 and a cylinder-piston assembly 6, the drive shaft is connected to the drive shaft of the engine, and the drive plate is installed On the driving shaft, the housing and the cover are assembled together, an oil storage chamber 7 is formed between the driven plate and the cover, and the driving plate, the housing and the A working chamber 8 is formed between the covers; the cylinder-piston assembly is mounted on the cover;

[0026] The active plate is provided with an oil outlet 21, the driven plate is located in the cover body, one end of the driven plate is fixedly connected to the active plate, the other end is opposite to the oil outlet, and can The oil outlet is blocked;

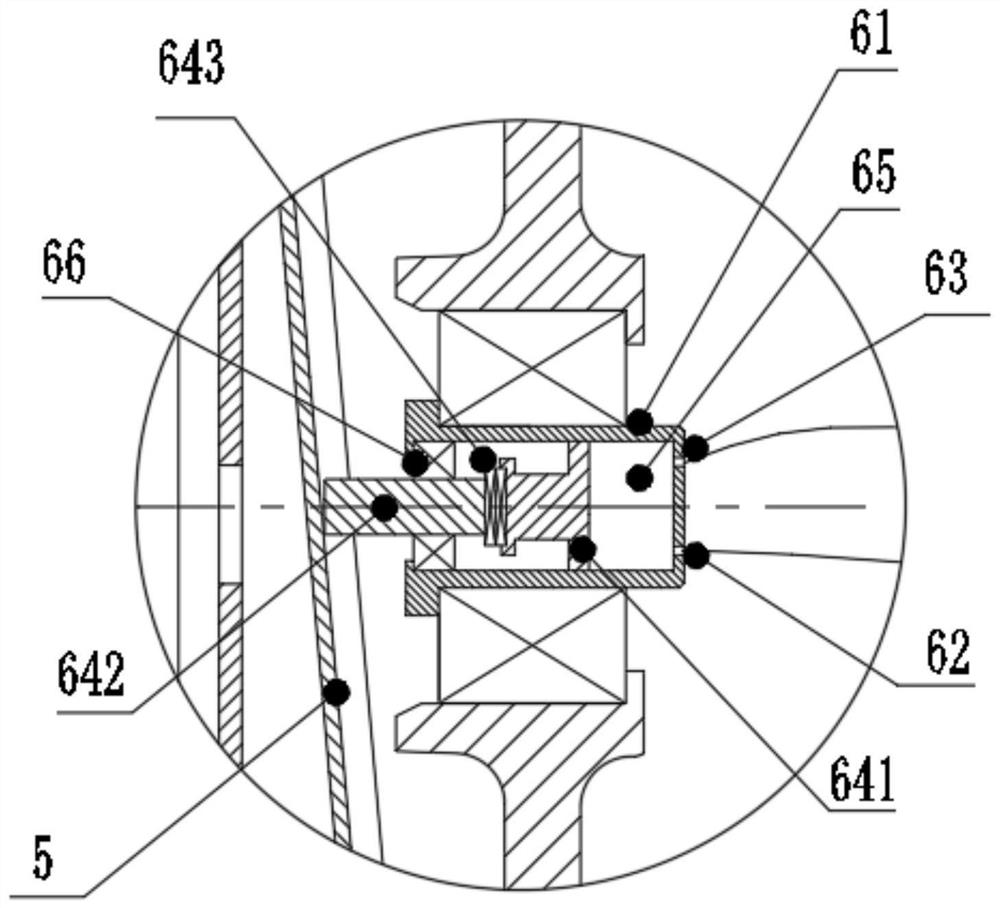

[0027] The cylinder-piston assembly 6 includes a cylinder 61, a piston outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com