Running electromechanical hybrid stepless speed regulation system for cotton picker

A technology of stepless speed regulation and cotton picking machine, which is applied in hybrid vehicles, charging stations, motor vehicles, etc., can solve the problems of not fully meeting production requirements and low transmission efficiency, and achieves improved operation efficiency, reduced energy consumption, To achieve the effect of electromechanical coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

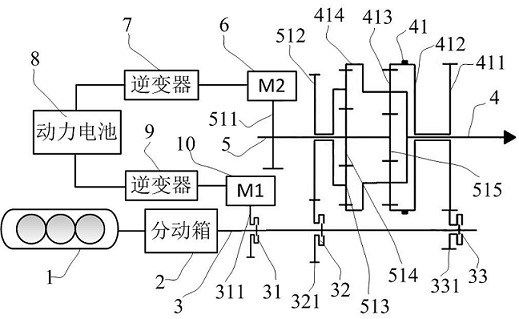

[0011]Among them, the cotton machine is started with pure electric pressing PE, and the cotton machine increases with the increase of the motor 6 output speed.

[0012]After the motor 6 reaches the maximum speed of the pure electric mode, the second clutch 32 is closed, the third clutch 33 is turned off, the brake 41 is closed, the right planetary ring wool 412 revolution is zero, and the cotton machine enters the pure mechanical PM1. The motor 6 starts working, and the cotton machine enters the electromechanical mixed non-set-output section, at which time the output speed of the motor 6 is improved, the mining machine is stressful.

[0013]Among them, when the cotton machine is used in the electromechanical mixing, the motor 6 reaches the maximum output speed of the stable output, the second clutch 32 is turned off, the third clutch 33 is closed, the brake 41 is broken, the cotton machine enters Pure mechanical two gear PM2. The motor 6 operates, and the cotton machine enters the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com