Device and method for monitoring natural gas pipeline leakage

A natural gas pipeline and natural gas technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of sensor cable failure, easy to be damaged by external force, and large diffusion range, so as to improve detection sensitivity, Avoid damage by external force and improve positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

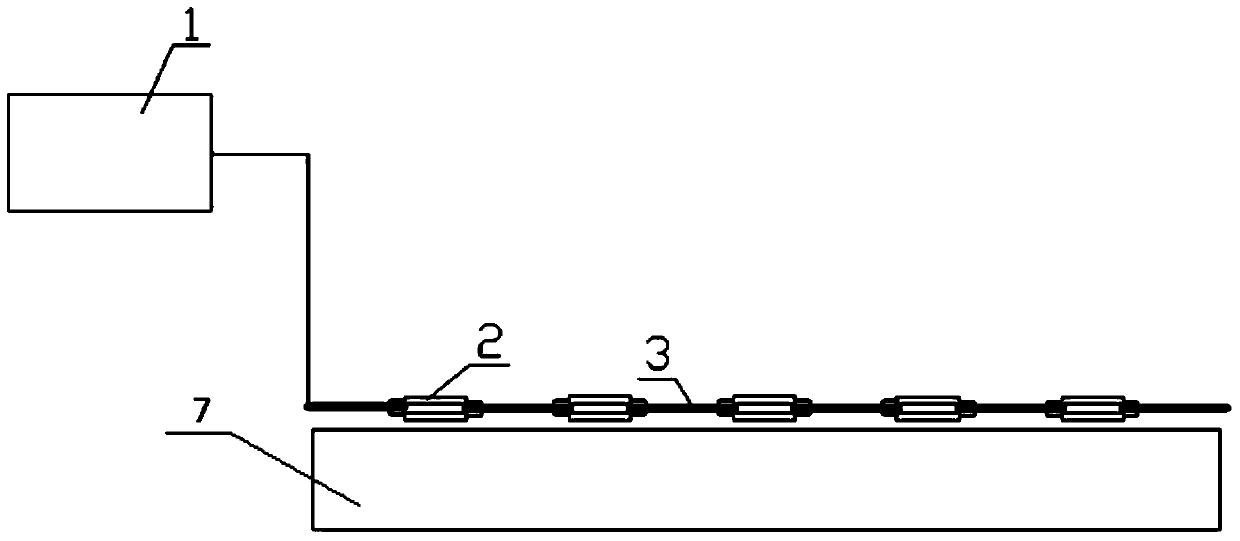

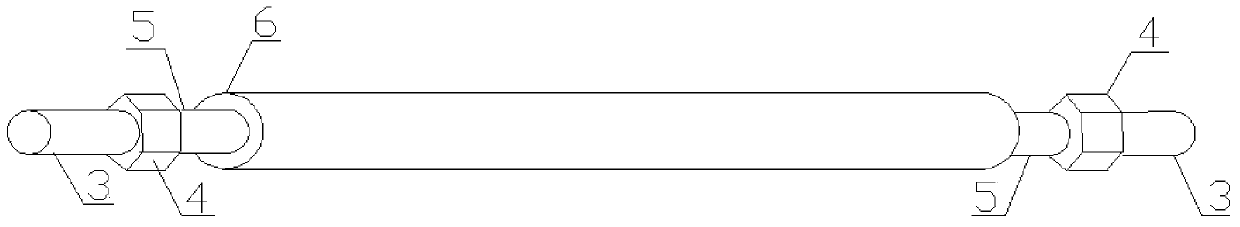

[0022] The invention provides a device for monitoring natural gas pipeline leakage, which includes a resistance detector 1, a front-end probe 2, an ordinary cable 3, a cable connector 4, a sensing cable 5, and a semi-permeable membrane detection tube 6. The resistance detector 1 is connected with ordinary cables 3, and the ordinary cables 3 are alternately connected with the front-end probes 2 through cable connectors 4. The front-end probes 2 include several semi-permeable membrane detection tubes 6 and several sensing cables 5, and the sensing cables 5 Inserted into the semi-permeable membrane detection tube 6,

[0023] In the above solution, the front-end probes 2 are evenly distributed to both sides in the form of sine waves, and the front-end probes 2 are fixed on the natural gas pipeline 7 .

[0024] In the above solution, the front end probe 2 is covered with a metal shell with mesh, and the metal shell with mesh is fixed on the natural gas pipeline 7. The size of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com