Anchor clips for steel strand fatigue test

A technology for fatigue testing and steel strands, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to correctly evaluate the fatigue performance of steel strands, uneven stress on steel strands, and fracture of steel strands, etc., to achieve Avoid fatigue sources, firm and reliable clamping, and prevent fatigue fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further description will be made below in conjunction with the accompanying drawings.

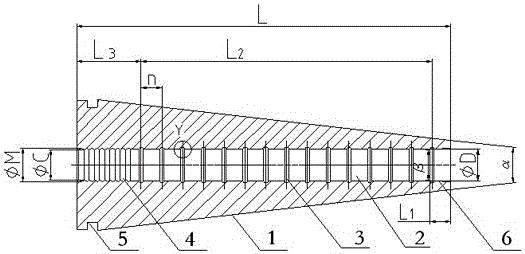

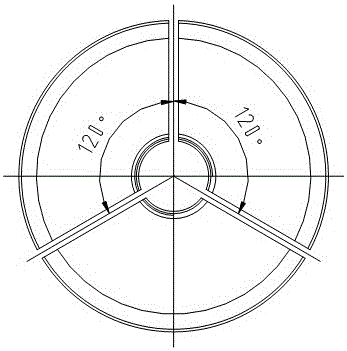

[0020] Such as figure 1 As shown, a steel strand fatigue test anchor clip of the present invention includes several clips

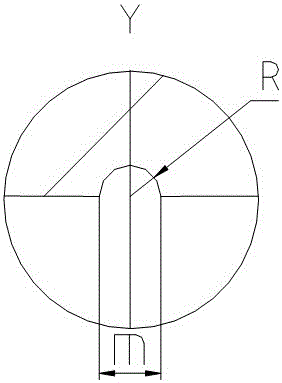

[0021] 1. It can be two or three, with a spacing of 2~3mm. Now, three clips 1 are used for illustration. The three clips 1 are surrounded together, the outer surface of the clip 1 is assembled into a conical surface with a narrow front and a wide rear, and the inner surface is surrounded by a cylindrical wire clamping groove 2, and a ring of tightening spring fixing groove is arranged at the rear of the conical surface 5. The inner surface of the clip 1 at the rear of the wire clamping groove 2 is provided with annular teeth 4, and the inner surface of the clip 1 at the middle and front of the wire clamping groove 2 is provided with a number of side-by-side and spaced annular pressure relief grooves 3. The tightening spring is embedded in the fixing groove 5 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com