Calculation Method of Composite Stress of Shock Absorber Valve Plate Under Arbitrary Axisymmetric Non-uniform Pressure

A technology of non-uniform pressure and compound stress, applied in the field of hydraulic shock absorbers, can solve the problem of failure to provide accurate and reliable, shock absorber valve plate breakage, and it is difficult to meet the precise design and strength calibration of shock absorbers and superimposed valve plates. nuclear and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

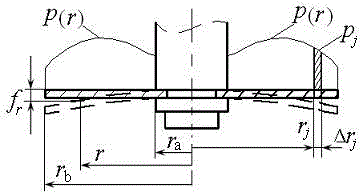

[0053] Example 1: The radius r of the inner circle of a ring valve plate of a shock absorber a =5.0mm, outer circle radius r b =8.5mm, elastic modulus E=2.0×10 11 Pa and Poisson's ratio μ=0.3, thickness h=0.3mm, valve port radius r o =8.0mm, apply uniform pressure p in the radius [5.0,8.0]mm section 0 =3.0MPa, apply linear non-uniform pressure on the [8.0,8.5]mm section Calculate the composite stress of the damper valve plate under this pressure.

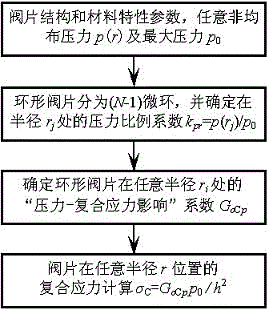

[0054] The calculation method of the composite stress of the damper valve plate under any axisymmetric non-uniform pressure provided by the example of the present invention, the calculation process is as follows figure 2 As shown, the specific steps are as follows:

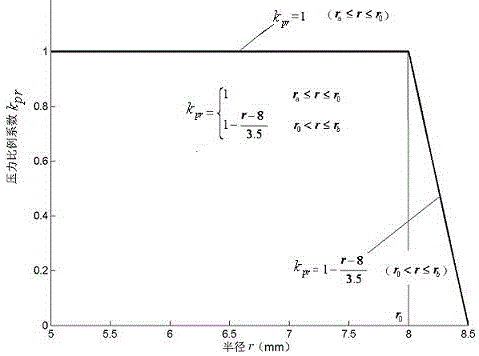

[0055] (1) Determined at the radius r j The microannular pressure proportional coefficient k at prj :

[0056] According to non-uniform pressure and its maximum value is p 0 =3.0MPa, the radius r of the inner circle of the damper valve plate a =5.0mm, outer...

Embodiment 2

[0084] Embodiment 2: The thickness of a shock absorber valve plate is h=0.3mm, and the radius of the inner circle is r a =5.0mm, outer circle radius r b =8.5mm, elastic modulus E=2.0×10 11 Pa and Poisson's ratio μ = 0.3, in [r a ,r b ] within the range of the secondary non-uniform pressure Calculate the composite stress of the damper valve plate under this pressure.

[0085] The calculation steps of Embodiment 1 are adopted, namely:

[0086] (1) Determined at the radius r j The microannular pressure proportional coefficient k at prj :

[0087] According to non-uniform pressure and its maximum value is p 0 =3.0MPa, the radius r of the inner circle of the damper valve plate a =5.0mm, outer circle radius r b =8.5mm, the radius interval [r a ,r b ] are equally divided into 70 parts, i.e. 70 microrings, the number of radius N=71; the width Δr=0.05mm of each microring; j The inner radius r of the microring at kj = r j , outer circle radius r tj = r kj +Δr=r j+1 ...

Embodiment 3

[0106] Embodiment 3: The structural parameters and material characteristic parameters of a shock absorber valve plate are the same as those in Embodiment 1, that is, the thickness h=0.3mm, and the inner circle radius r a =5.0mm, outer circle radius r b =8.5mm, elastic modulus E=2.0×10 11 Pa and Poisson's ratio μ = 0.3, in [r a ,r b ] within the range of applied sinusoidal non-uniform pressure Calculate the composite stress of the damper valve plate under this pressure.

[0107] The calculation steps of Embodiment 1 are adopted, namely:

[0108] (1) Determined at the radius r j The microannular pressure proportional coefficient k at prj :

[0109] According to non-uniform pressure and its maximum value is p 0 =3.5MPa, the radius r of the inner circle of the damper valve plate a =5.0mm, outer circle radius r b =8.5mm, the radius interval [r a ,r b ] are evenly divided into 70 parts, that is, 70 microrings, the number of radiuses N=71, and the width of each microri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com