Method and device for controlling a variable valve timing mechanism of an internal combustion engine

A technology of valve mechanism and internal combustion engine, which is applied in the direction of internal combustion piston engine, electrical control, engine control, etc., which can solve the problems of limiting driving comfort, driving unevenness, reducing driving comfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

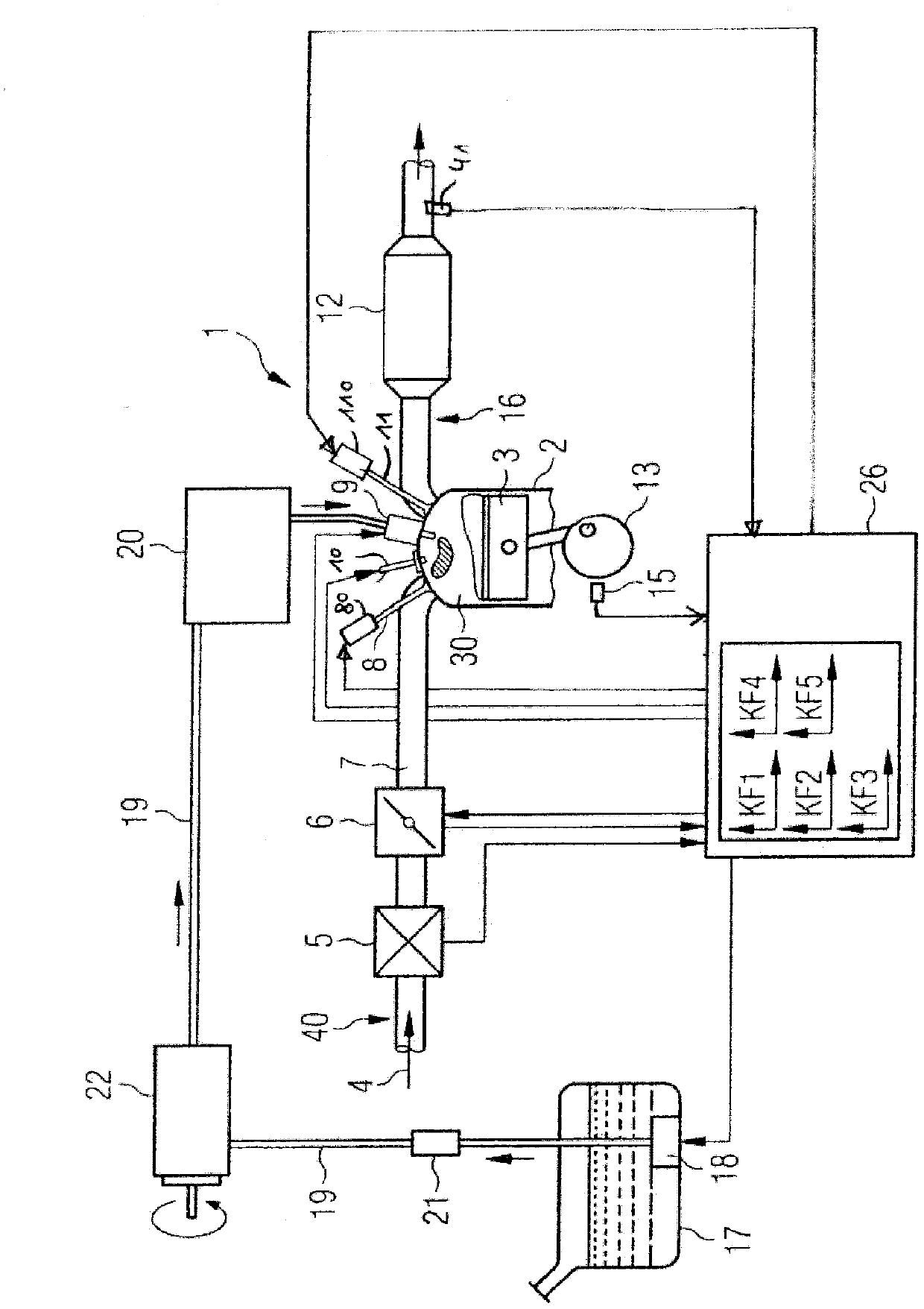

[0029] figure 1 Internal combustion engine 1 is shown schematically.

[0030] The internal combustion engine 1 includes four cylinders 2 , of which only one cylinder is therefore shown for reasons of clarity. The description for this cylinder also applies analogously to the other cylinders. Arranged within the cylinder 2 is a piston 3 which can reciprocate within the cylinder 2 . The internal combustion engine 1 also includes an intake branch 40 , in which an intake port 4 for intake of fresh air, an air mass sensor 5 , a throttle valve 6 and an intake line 7 are arranged downstream. The intake branch 40 opens into the combustion chamber 30 delimited by the cylinder 2 and the piston 3 . The fresh air required for combustion is fed into the combustion chamber 30 via an intake branch 40 , wherein the fresh air supply is controlled by opening and closing at least one intake valve 8 .

[0031]The internal combustion engine 1 shown here is an internal combustion engine 1 with d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap