Method for isolating quantity errors of a fuel amount and an air amount supplied to at least one cylinder of an internal combustion engine

A technology of internal combustion engine and fuel quantity, applied in the direction of internal combustion engine testing, internal combustion piston engine, analysis of materials, etc., can solve the problems of inaccurate pre-control, burden, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

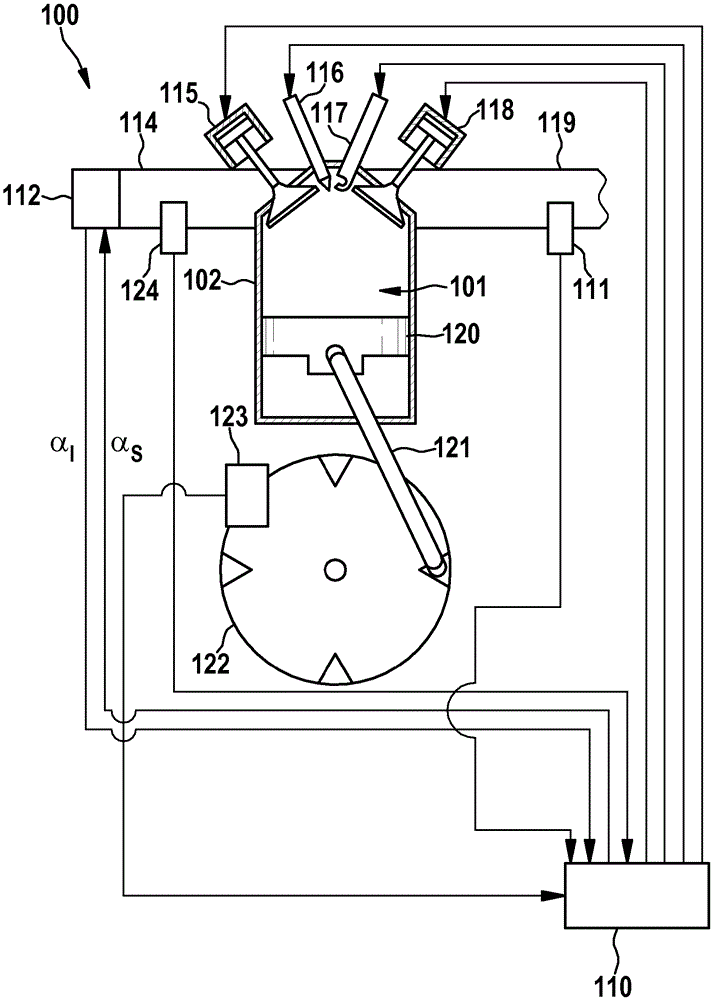

[0032] exist figure 1 , a section of an internal combustion engine, for example a gasoline motor or a diesel motor, is shown schematically and designated 100 . Internal combustion engine 100 has a computing unit designed as controller 110 , which is set up to carry out an embodiment of the method according to the invention. Additionally, the internal combustion engine 100 includes multiple cylinders, of which only the first cylinder 102 is shown for clarity. The first cylinder block 102 of the internal combustion engine 100 includes a combustion chamber 101 , which is supplied with a fresh air volume via a throttle flap 112 and an intake line 114 arranged between the throttle flap 112 and an inlet valve 115 . Arranged in the suction pipe is an air quality sensor 124 which detects fresh air as the supplied gas mass or gas quantity. The air quality sensor 124 transmits the measured value for the supplied air quantity to the controller 110 .

[0033] Furthermore, a fuel quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com