Feed feeding cart

A feed and frame technology, which is applied in the field of feed feeding vehicles, can solve the problems of high labor intensity, unsuitability for feed transfer, and large space occupation of transshipment workers, and achieve the effect of compact structure, high power, and improved conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

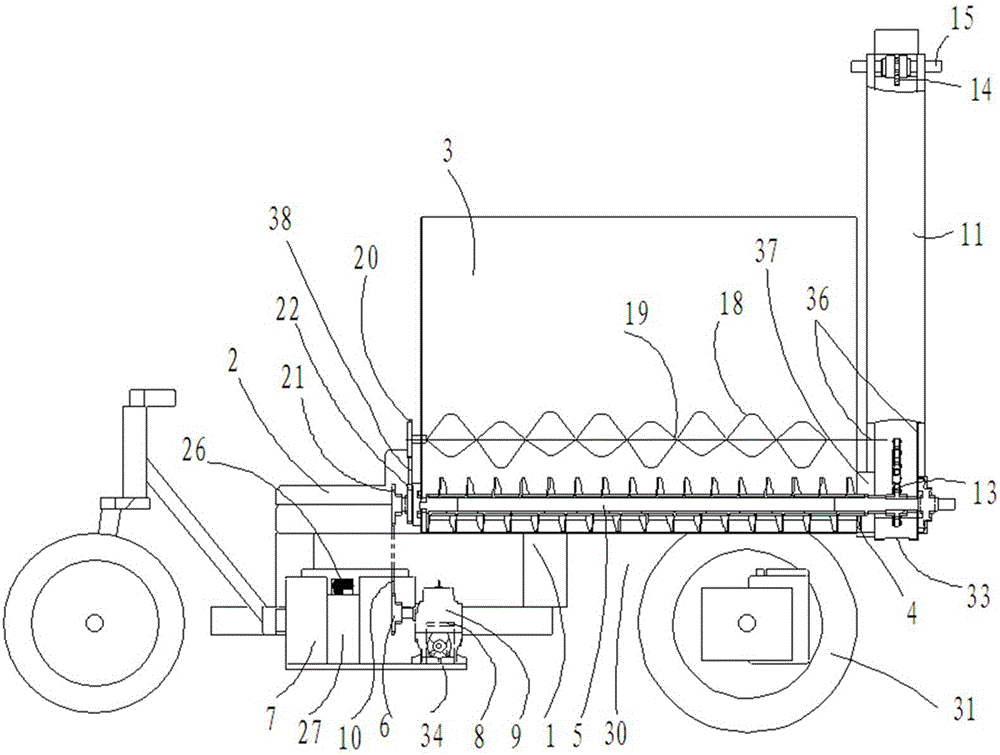

[0024] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

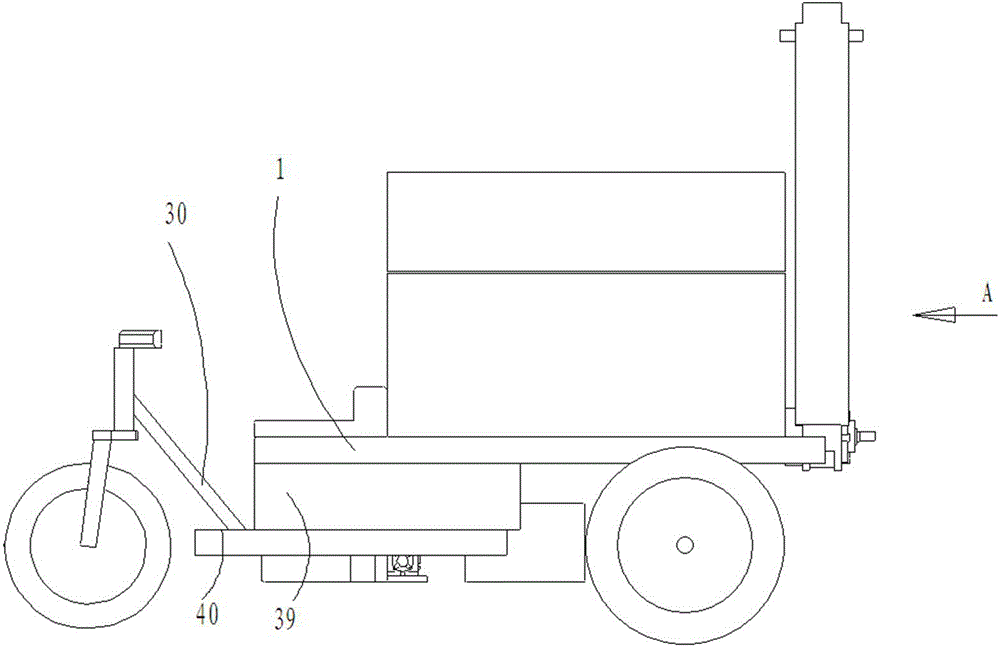

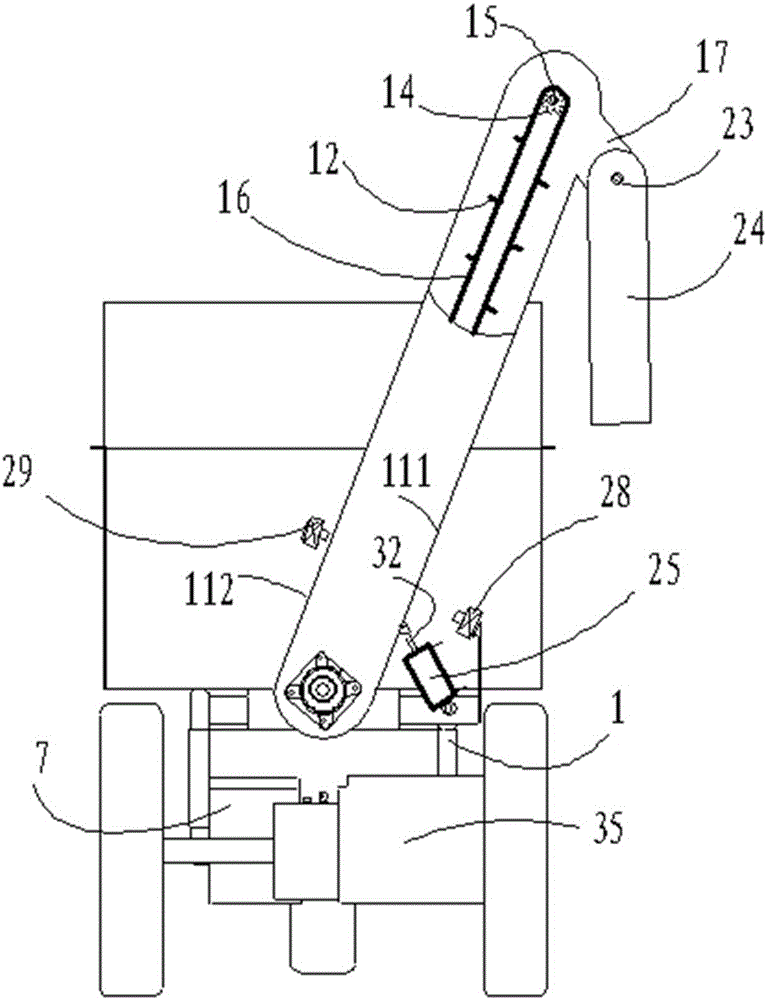

[0025] Such as figure 1 As shown, a feed feeding vehicle comprises a vehicle frame 1, a seat 2 is provided at the front of the vehicle frame, a walking motor is provided at the bottom of the seat 2, and the walking motor is connected with a DC power supply 7, and the vehicle frame at the rear of the seat 2 is provided with A hollow box 3 with an upper opening, the rear end of the box 3 is provided with a box discharge port 4, the lower part of the inner cavity of the box 3 is provided with a conveying auger shaft 5 along the front and rear direction of the car, and the front end of the auger shaft 5 protrudes Outside the front wall of the box, the rear end of the auger shaft extends from the box outlet 4 to the rear wall of the box, the front end of the auger shaft 5 is supported on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com