McPherson automobile front suspension structure

A front suspension, Ferson-style technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of increasing the complexity of the force of the coil spring, the wear and failure of the front pillar before acceleration, and the inability to adjust the inclination angle of the kingpin, etc. , to achieve the effect of facilitating adjustment, prolonging fatigue life and reducing steering friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

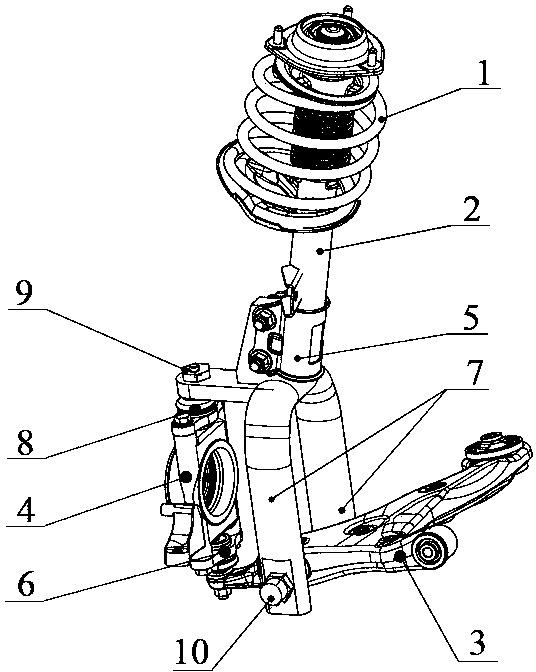

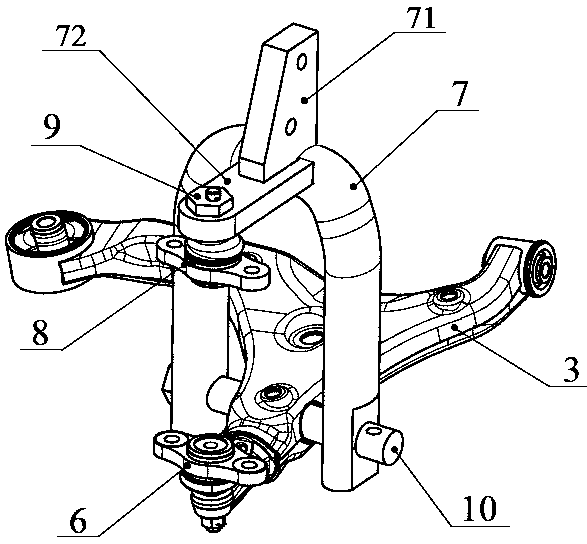

[0030] Such as figure 1 , the MacPherson car front suspension structure includes a coil spring 1, a barrel shock absorber 2, a lower swing arm 3, a steering knuckle 4 and a shock absorber bracket 5, and the coil spring 1 is set on the barrel shock absorber on the shock absorber 2; the lower end of the steering knuckle 4 is hinged on the outer end of the lower swing arm 3 through the lower ball joint 6, and the inner side of the lower swing arm 3 is tightly connected with the sub-frame 11 of the vehicle, so that the entire front suspension is installed onto the subframe.

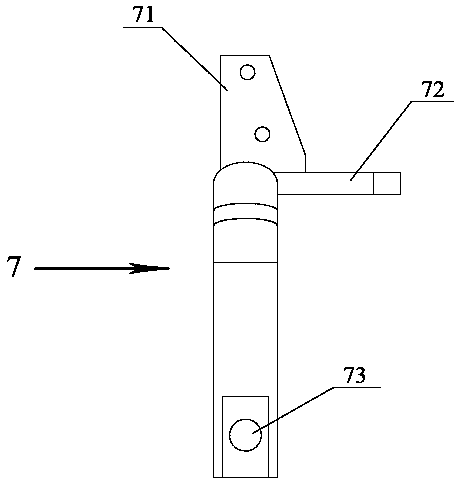

[0031] In order to prevent the front pillars (including coil spring 1, barrel shock absorber 2, etc.) The two legs of the U-shaped support 7 are straddled and hinged on the lower swing arm 3. The two legs at the lower end of the U-shaped support 7 are provided with relative pin holes 73. In the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com