Front-and-back breathable type leather shoe

A front-to-back ventilation and air-permeable technology, applied to uppers, footwear, boot legs, etc., can solve the problems that sweat cannot be ventilated and dried in a short time, shorten the service life of leather shoes, and make it difficult to wear, so as to reduce sweating on the feet , Breathable effect is remarkable, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

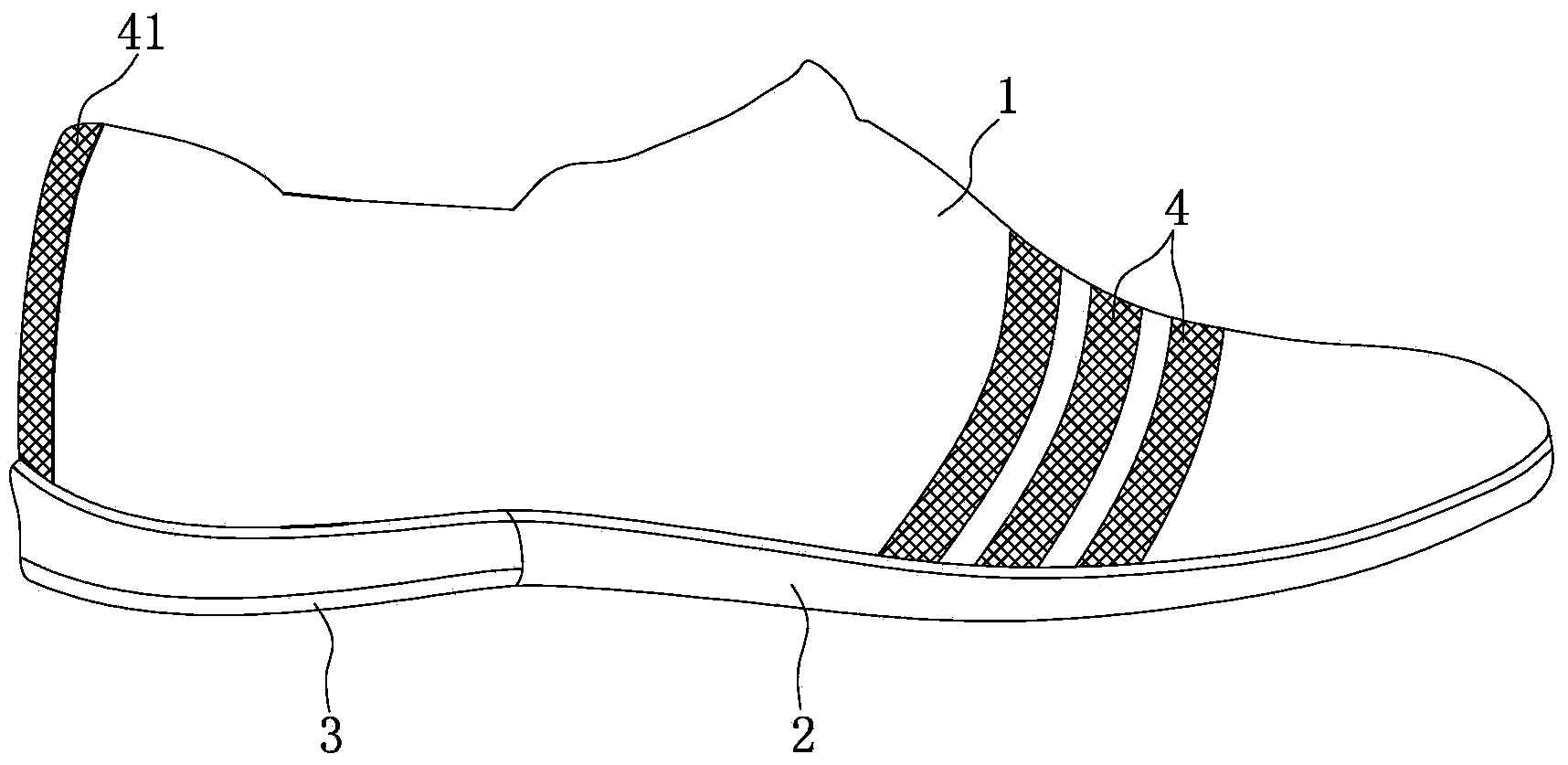

[0016] Such as figure 1 As shown, the present invention is composed of three parts: the upper 1, the sole 2 and the heel 3. The sole 2 and the heel 3 are integrally structured and made of high-strength wear-resistant plastic. The front end of the sole 2 and the shoe The rear ends of the heels 3 are all upturned, and the top surface of the sole 2 is distributed with protrusions for massaging. The upper 1 is located above the sole 2 and is made of leather. The shape of the upper 1 and the connection with the sole 2 are the same as those of the prior art, and will not be repeated here.

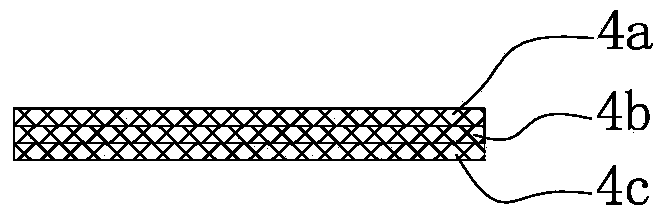

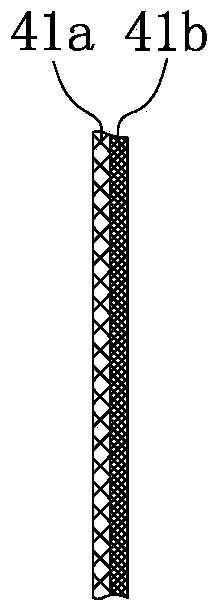

[0017] Such as figure 1 , figure 2 with image 3 As shown, a plurality of first openings with a width of 8-18 mm are provided on the front of the shoe upper 1 from front to back, and the first openings extend from the left side of the sole 2 to the right side along the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com