Die separating and combining mechanism of storage battery cast-welding machine

The technology of casting welding mold and casting welding machine is applied in the field of battery processing equipment components, which can solve the problems of low efficiency, large labor demand, and high risk of physical injury of workers, and achieves the effect of simple structure, easy processing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

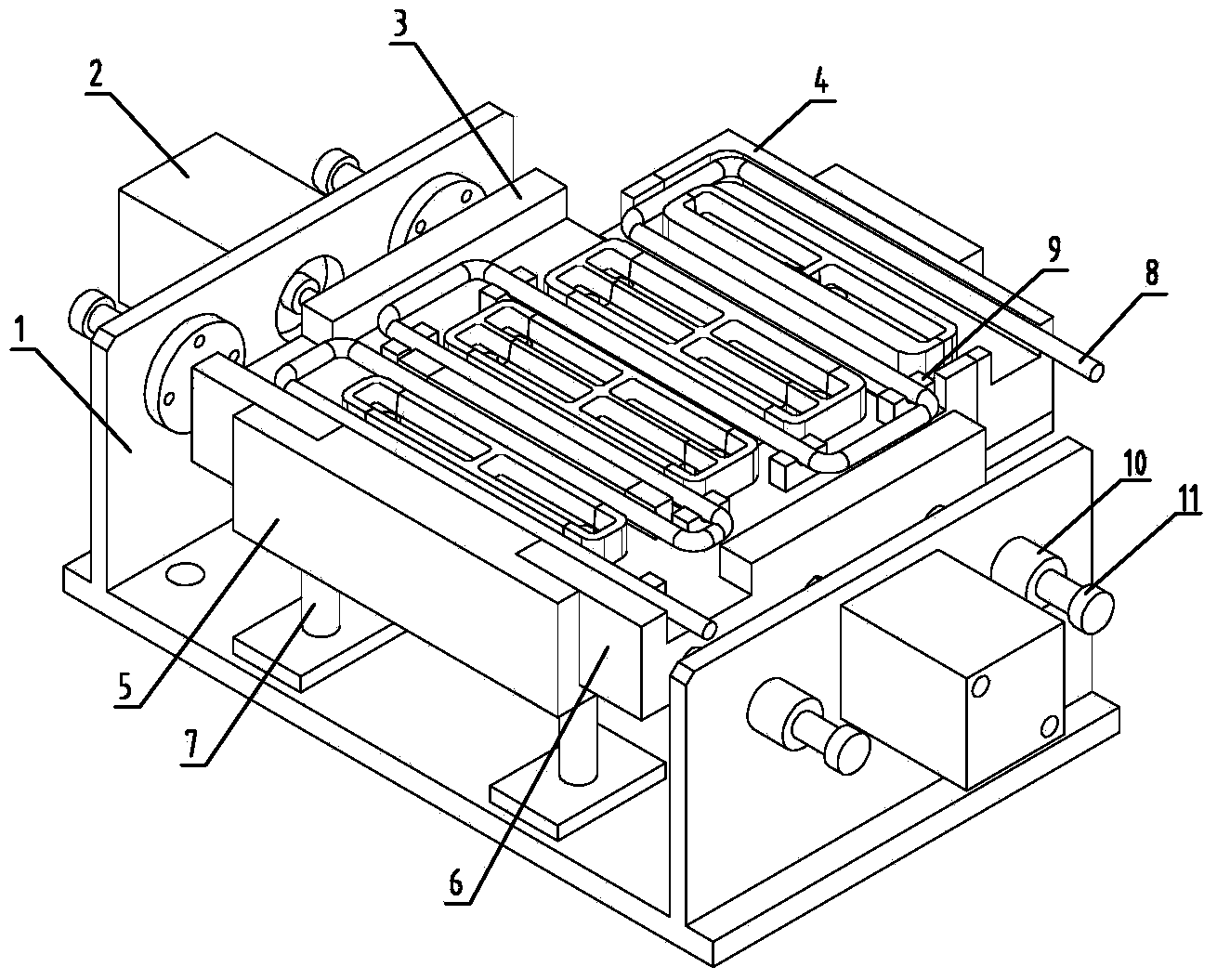

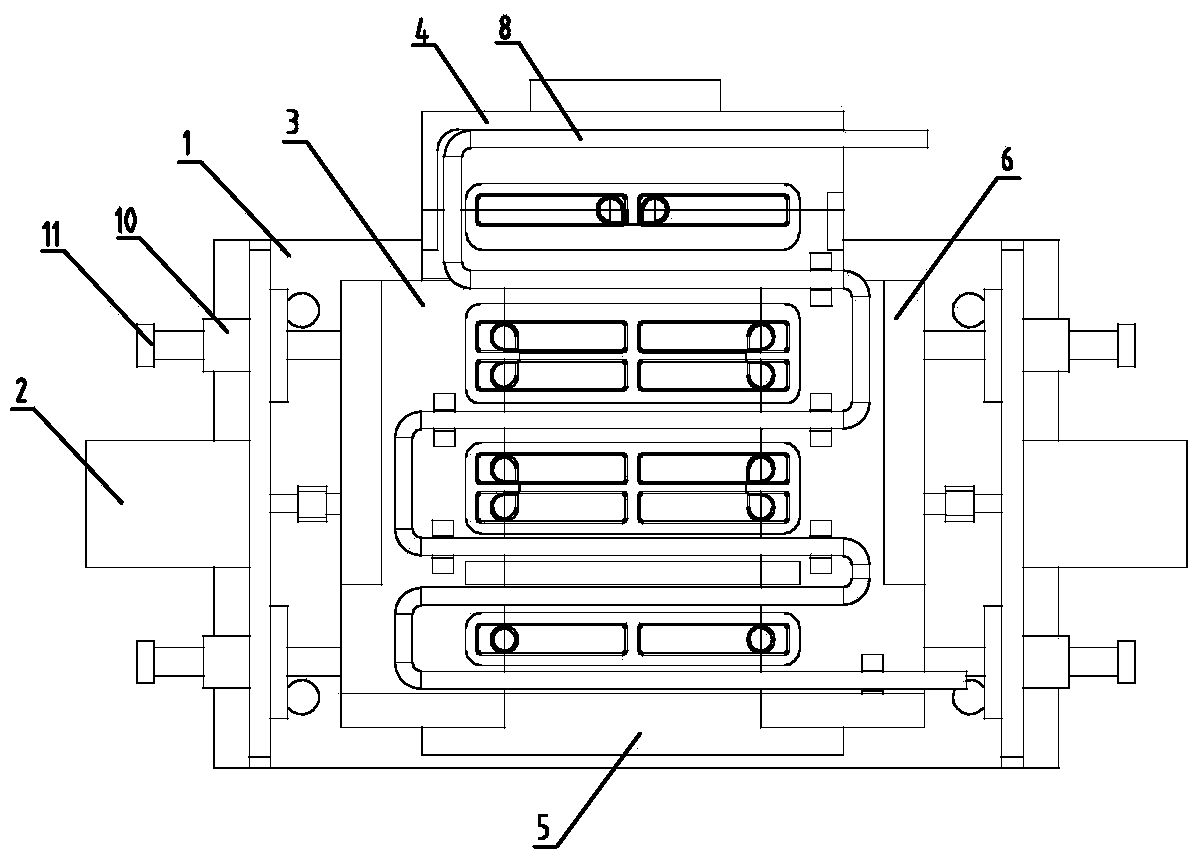

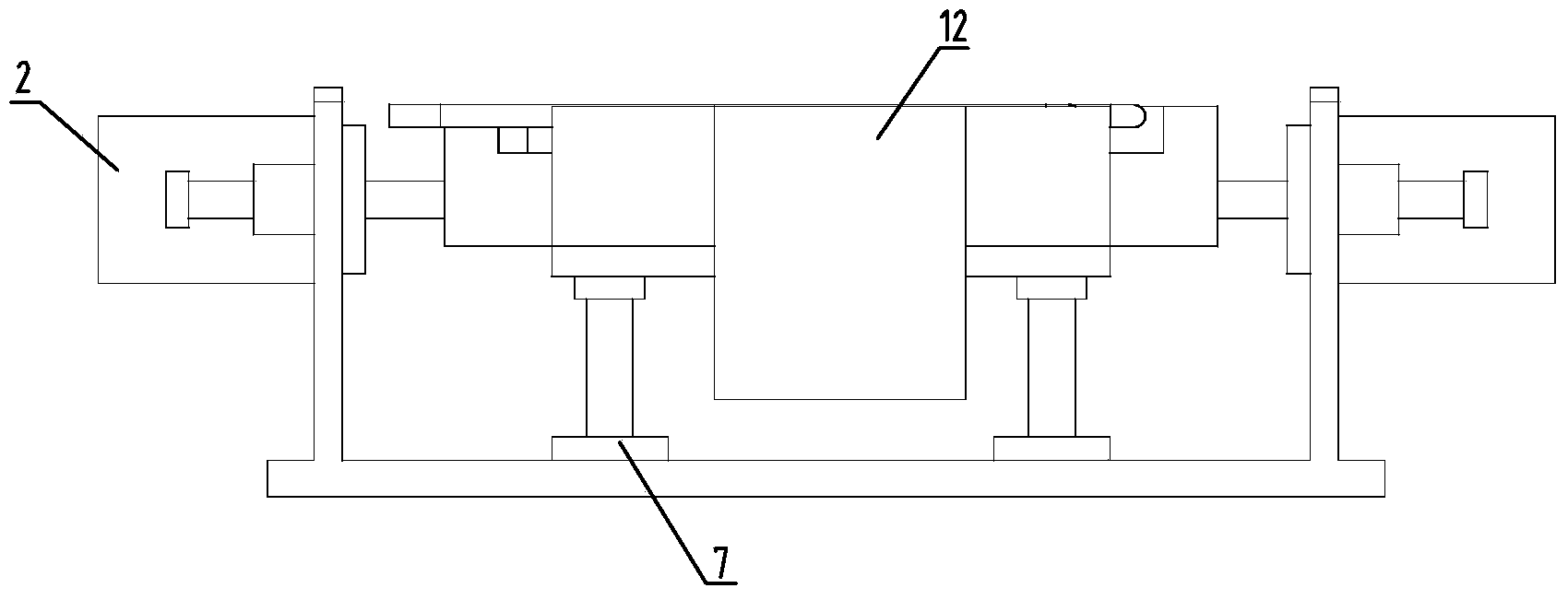

[0018] like figure 1 -- Figure 5 As shown, the mold opening and closing mechanism of the battery casting and welding machine in this embodiment includes a support frame, two left and right thin cylinders, a left mold, a main mold, a right mold, a side mold, an induction heating coil, 4 supporting columns, 4 connecting shafts, 4 flanged linear bearings, and a double-axis cylinder, the main mold and the supporting frame are connected by the 4 supporting columns, the left and right The mould is connected with a thin cylinder extension shaft and two connecting shafts at the same time, the thin cylinder is fixed on the support frame, the double shaft cylinder is installed on the back of the main mould, the double shaft cylinder The working end of the induction heating coil is connected with the side mold, and the induction heating coil is placed in the slot of the left, right, main and side molds with small spacers.

[0019] In order to make the left, right, side molds and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com