Manipulator for seam welding of oil heater pieces

A technology of oil sill and manipulator, applied in the field of manipulator, can solve the problems of welding seam deviation, labor intensity of non-straight workers, etc., and achieve the effects of improved production efficiency, convenient installation and removal, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

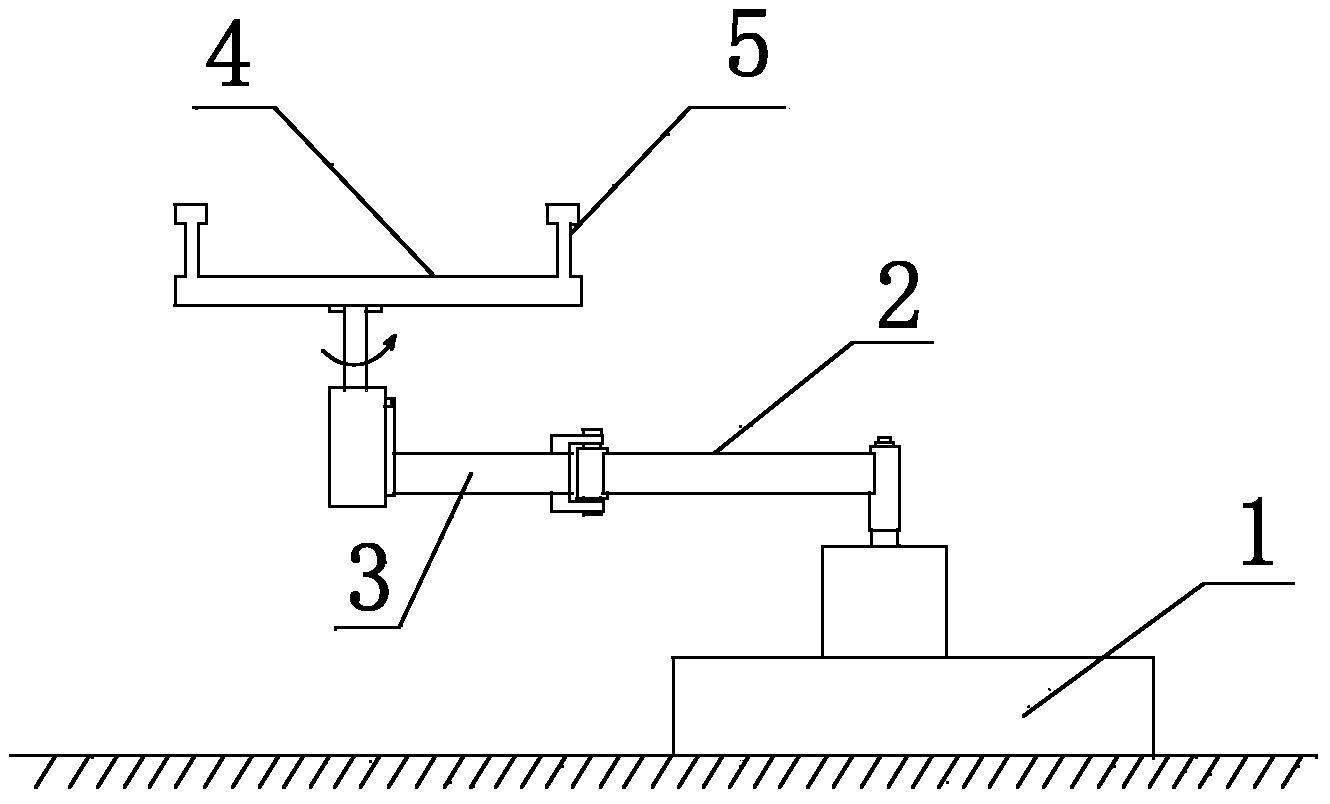

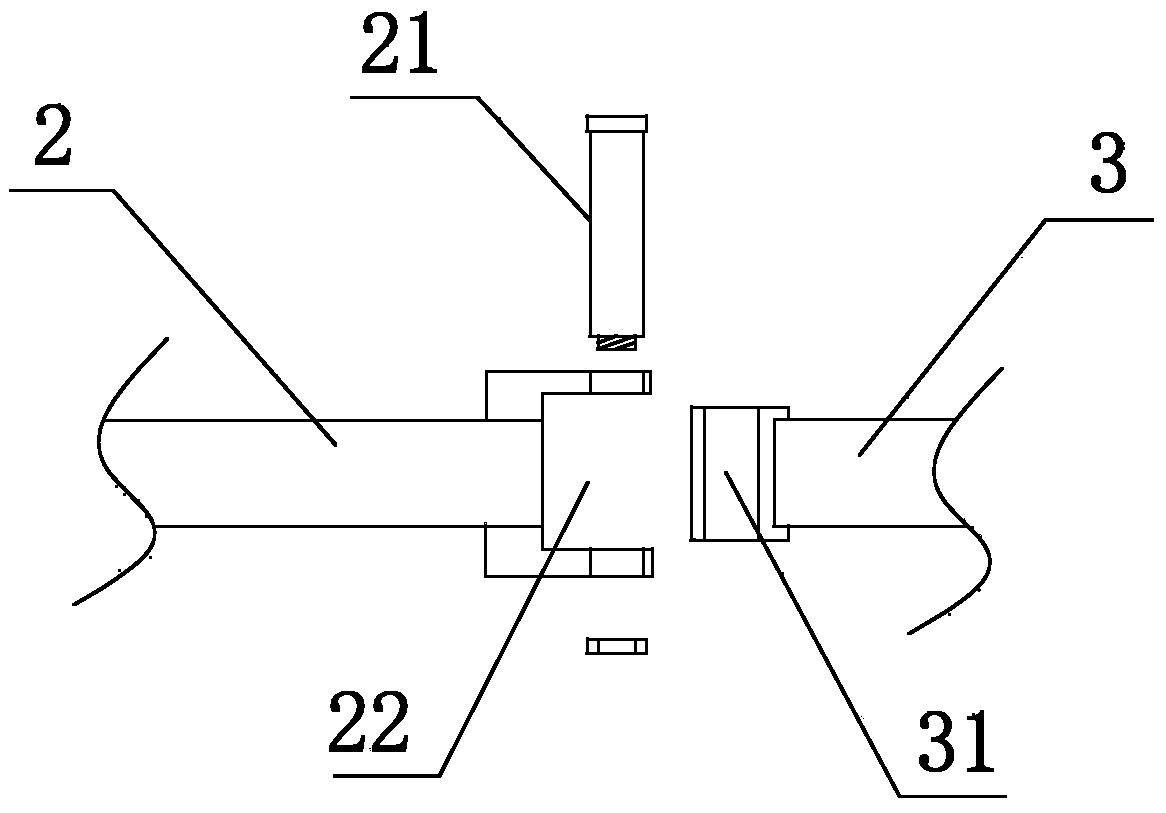

[0029] like figure 1 As shown, a manipulator for seam welding of oil slugs includes: a bracket 1 , a large arm 2 , a small arm 3 and an oil sill tray 4 .

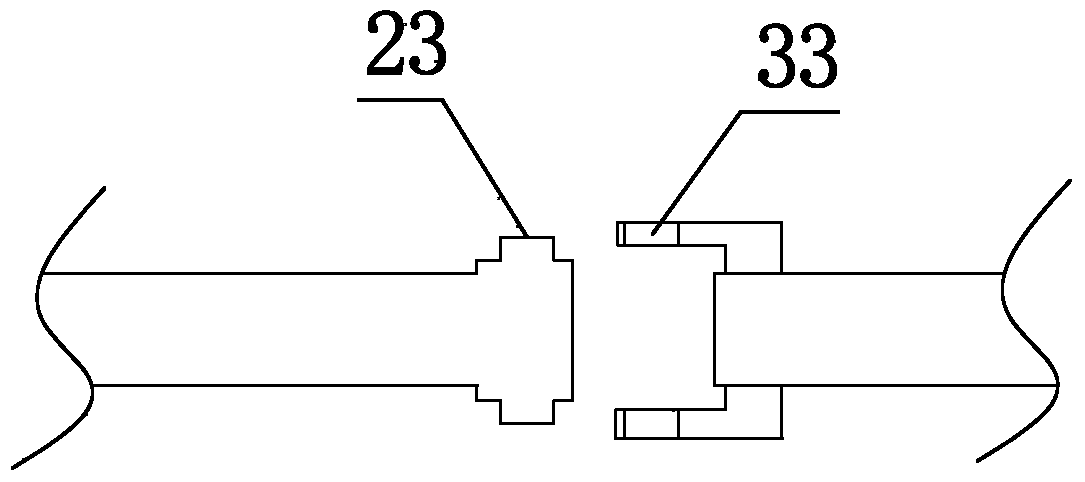

[0030] Among them, the big arm 2, the small arm 3 and the oil tray 4 are arranged horizontally, one end of the big arm 2 is rotatably connected with the bracket, and the other end of the big arm 2 is rotatably connected with one end of the small arm 3, on the other end of the small arm 3 An oil sump tray 4 is installed to be rotated by a rotating shaft.

[0031] In order to conveniently fix the oil-trap to be welded on the oil-trap 4 , an oil-trap fixing device 5 is provided on the upper surface of the oil-tray 4 . In the present embodiment, it is preferable that the oil-trap fixing device 5 is two positioning posts arranged on the upper surface of the oil-trap tray, which facilitates the placement and removal of the oil-trap, and is very convenient to operate.

[0032] In actual work, first place the oil sill on the fixi...

Embodiment 2

[0038] like Figure 5 As shown, a manipulator for seam welding of oil slugs includes: a bracket 1 , a large arm 2 , a small arm 3 and an oil sill tray 4 . Among them, the big arm 2, the small arm 3 and the oil tray 4 are arranged horizontally, one end of the big arm 2 is rotatably connected with the bracket, the other end of the big arm 2 is rotatably connected with one end of the small arm 3, on the other end of the small arm 3 An oil-trap tray 4 is rotatably installed through a rotating shaft; an oil-trap fixing device 5 is provided on the upper surface of the oil-trap tray 4 .

[0039] The present embodiment provides a manipulator for seam welding of oil sills, the structure of which is basically the same as that of the first embodiment, and the difference is:

[0040] The manipulator also includes a support plate 6, the bracket 1 is mounted on the support plate 6, an upwardly extending connecting rod 7 is fixed on the upper surface of the oil cooling tray 4, and the oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com