Three-rotation-spherical-parallel-connection mechanism

A three-rotation, spherical technology, used in manipulators, program-controlled manipulators, metal processing mechanical parts, etc., can solve the problems of unguaranteed shape and reduced stiffness, and achieve good stiffness, small moment of inertia, and fast motion response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

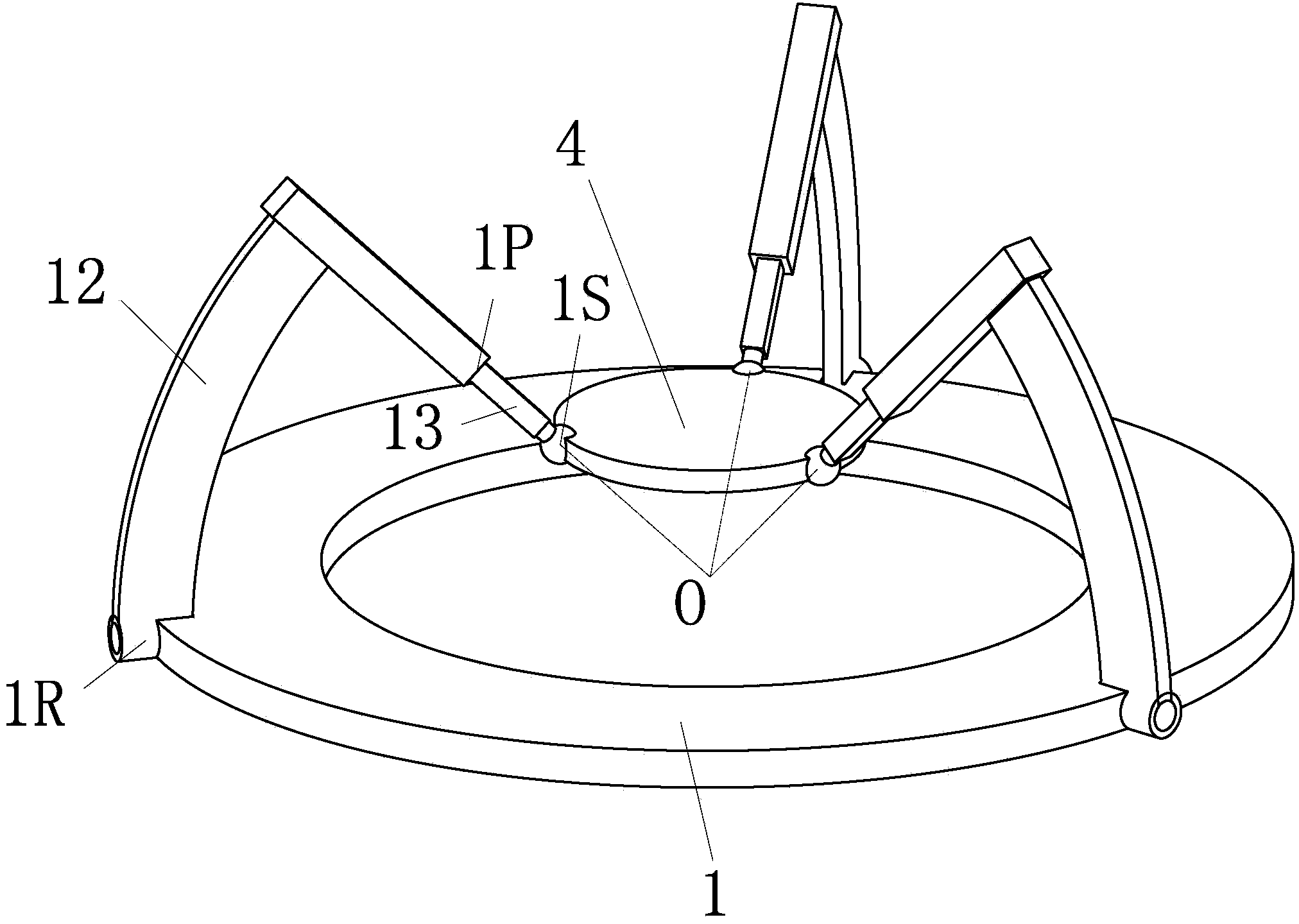

[0015] Such as figure 1 As shown, a three-rotation spherical parallel mechanism includes a frame 1 , a moving platform 4 and three branches connecting the frame 1 and the moving platform 4 .

[0016] Each of the three branches is sequentially composed of a rotating pair 1R, an arc-shaped connecting rod 12, a moving pair 1P, a guide rod 13, a spherical hinge 1S, and a circular moving platform 4 (the three branches have the same structure).

[0017] The radius of the arc-shaped connecting rod 12 in each branch is equal to the radius of the circular frame 1, the axis of the rotating pair 1R and the axis of the moving pair 1P form an angle of 45°, and the axis of the moving pair 1P passes through the spherical center of the spherical joint 1S and points to the circle The center O of the bracket (the arc lengths or distances between the centers of the two ball j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com