Simple fast pressing plate

A simple, platen technology, applied in the mechanical field, can solve the problems of reduced accuracy, offset of the drill bit center, insufficient pressing force, etc., and achieves the effects of high efficiency, improved production efficiency, safety and reliability, and fast pressing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

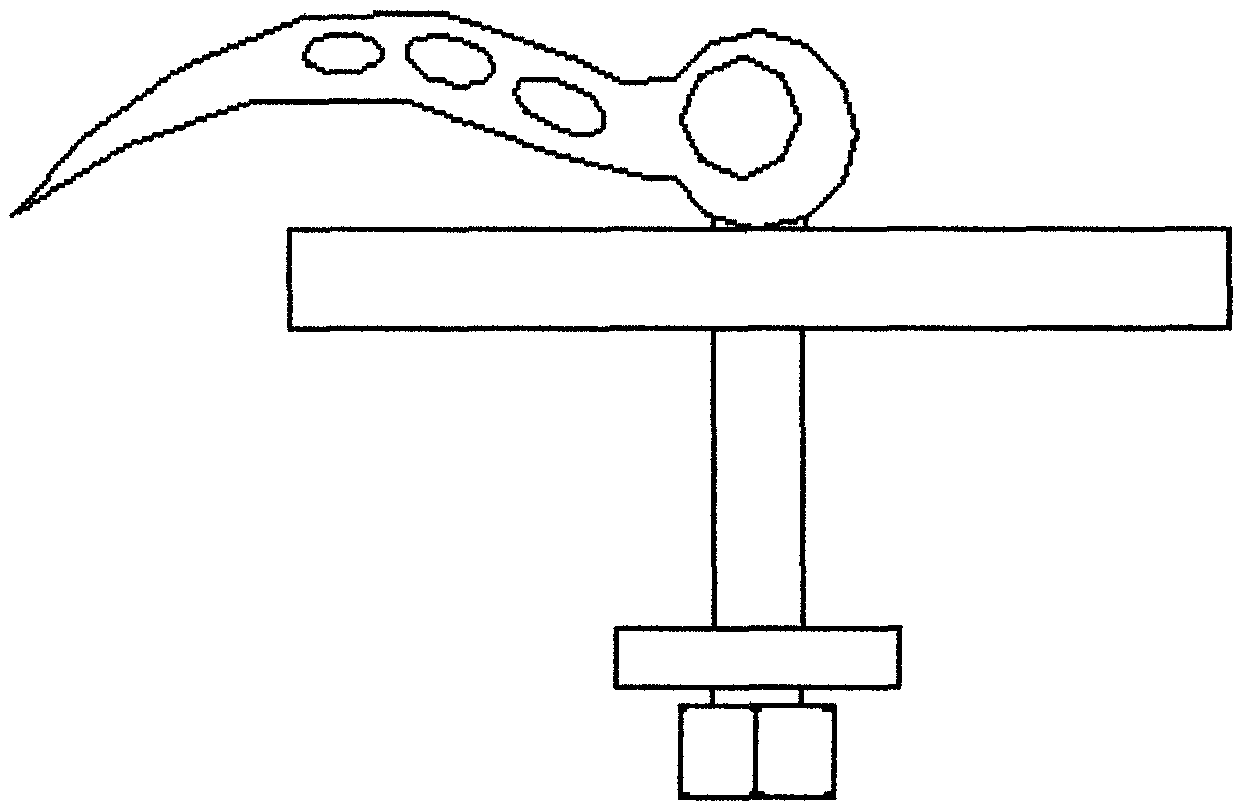

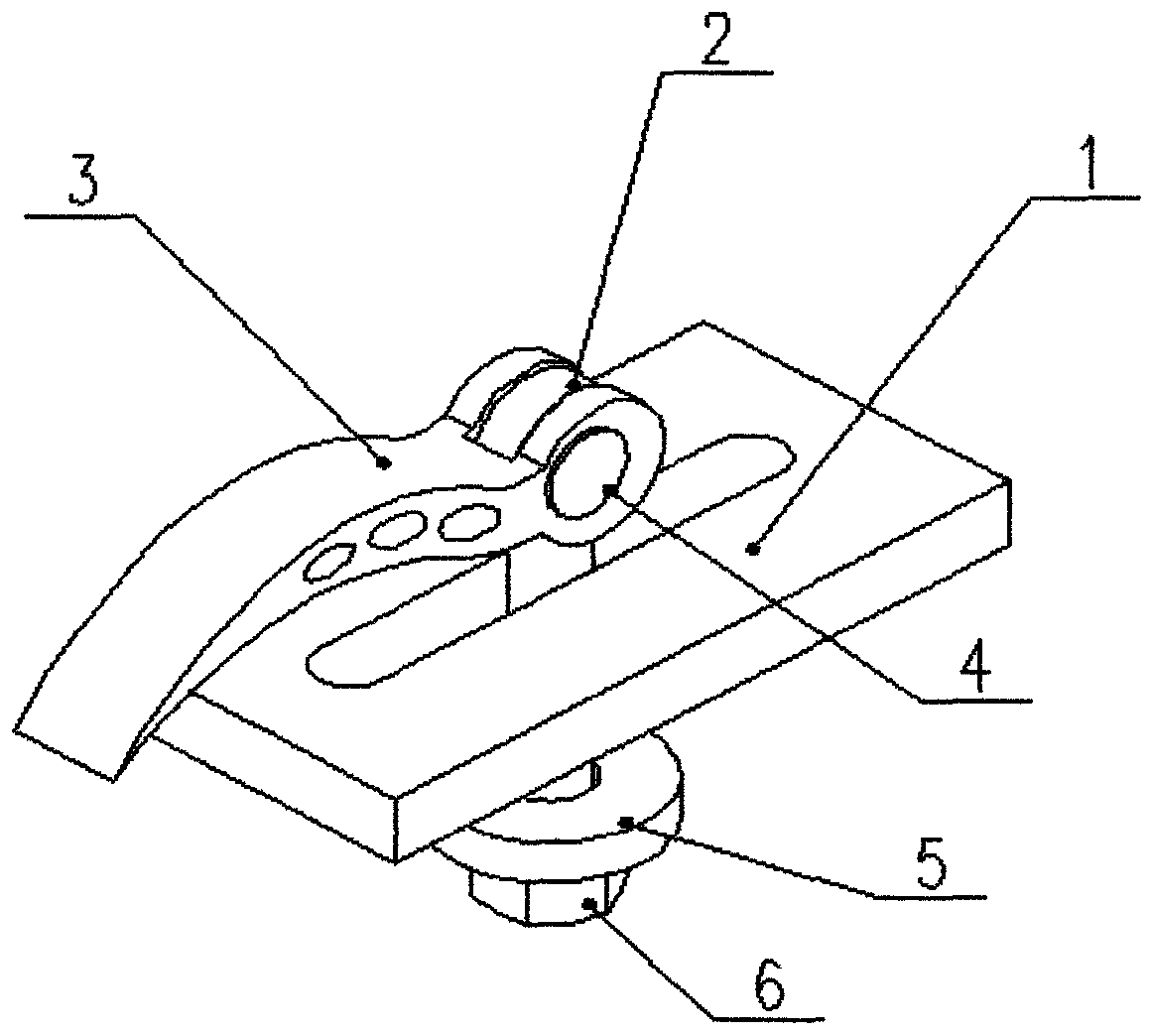

[0010] Such as figure 1 , 2 Shown, the present invention comprises pressing plate, screw rod, handle, eccentric cam, washer, nut and forms. The screw rod passes through the eccentric cam horizontally, requiring a gap, and can rotate freely. A slot is opened at one end of the handle, and the slot is connected with the screw rod. A groove is arranged in the middle of the pressing plate, and the width of the groove only needs to be greater than the width of the screw rod, and the screw rod passes through the pressing plate and is connected with the washer nut. When in use, as long as it is installed on the drilling platform of the drilling machine, it can be adjusted freely according to the height of the parts to meet the drilling requirements. During production, the material is required to be No. 45 steel and heat treatment is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com