The support assembly of the special universal grinding machine for nuclear power bearing ring processing

A technology for bearing rings and universal grinding machines, which is applied to the parts of grinding machine tools, grinding machines, and grinding workpiece supports, etc. It can solve the problems of difficult adjustment to the correct position, displacement, and difficult adjustment, so as to reduce adjustment The total number of times, the adjustment method is simple, and the effect of reducing the difficulty of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

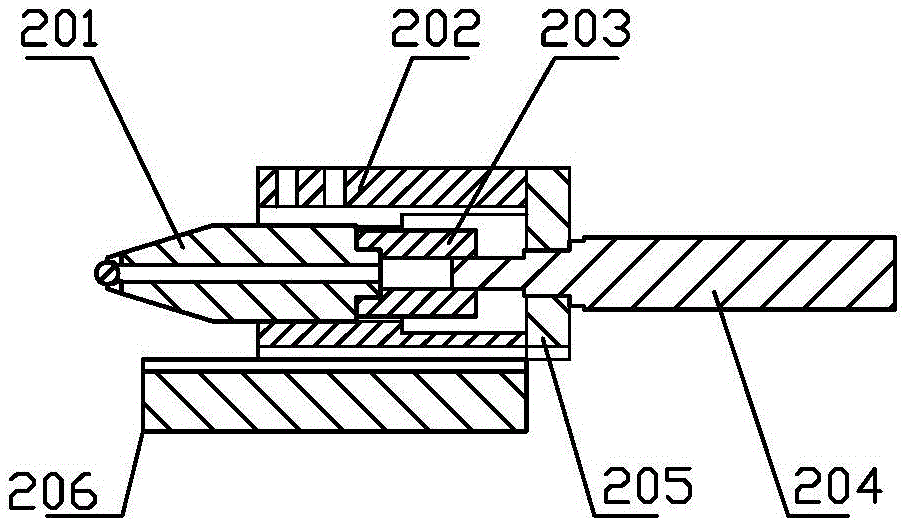

[0043] A diamond roller dresser for a universal grinding machine dedicated to processing nuclear power bearing rings, installed on the special universal grinding machine for processing nuclear power bearing rings, the support assembly 200 includes: a support head 201, a casing 202, a shaft coupling 203, an adjustable Screw propeller 204, propeller fixed plate 205, base 206, base 206 is fixed on the workpiece translation mechanism 8, support head 201 is connected with adjustable screw propeller 204 by shaft coupling 203, and the connecting part is in shell 202, and shell One end of 202 is installed with a propeller fixing plate 205 to limit the adjustable screw propeller 204; rotate the adjustable screw propeller 204 to adjust the support head 201 against the workpiece to be processed;

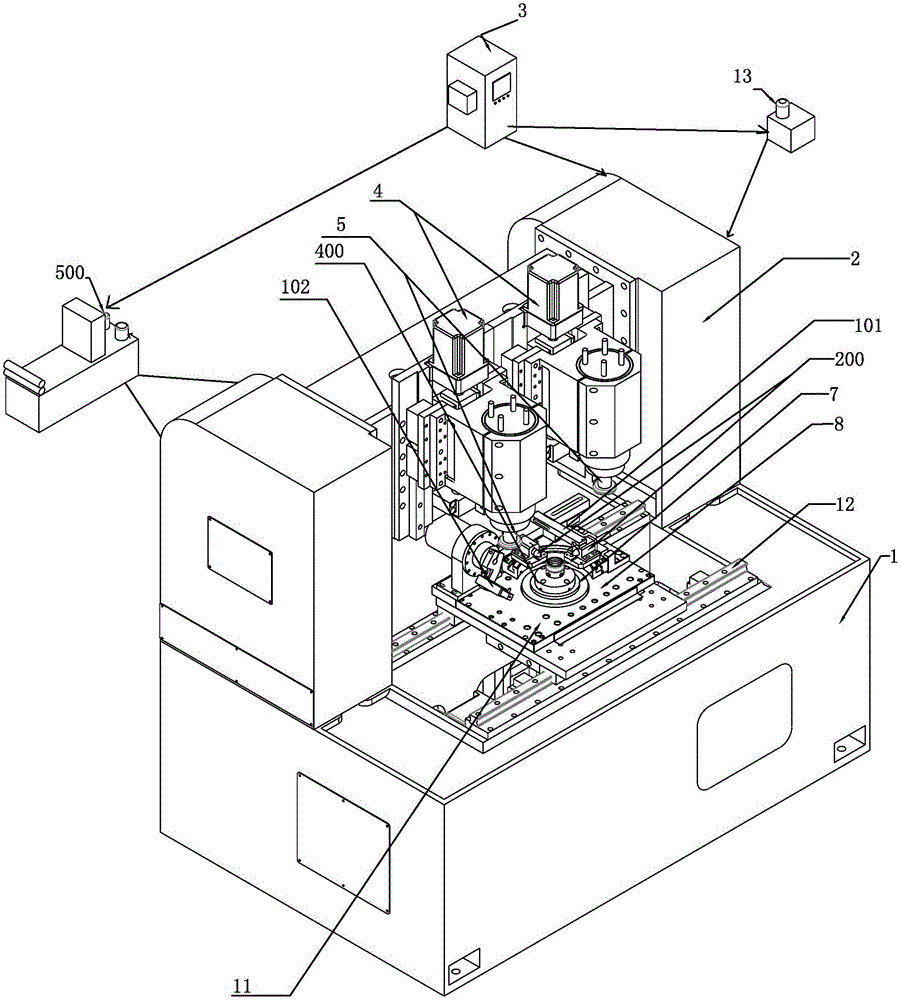

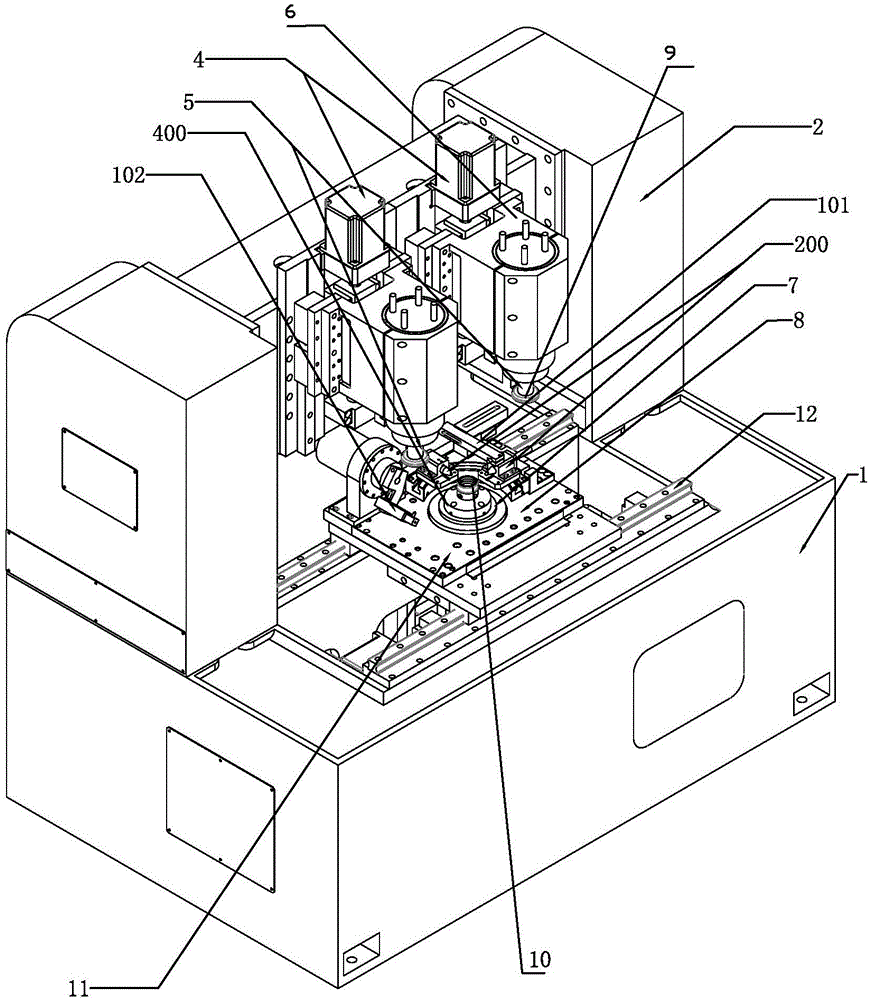

[0044] The special universal grinding machine for nuclear power bearing ring processing also includes a machine base 1, a bed 2, a hydraulic system 13, an electric control system 3, a servo syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com