Blue-light-resistant protective film and preparation method thereof

An anti-blue light, protective film technology, applied in chemical instruments and methods, luminescent coatings, film/flake adhesives, etc., can solve problems such as cell death and damage to vision, achieve uncomplicated processes, reduce irritation, and protect eye effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the characteristics of the present invention, technical means and the specific purpose and function achieved, and analyze the advantages and spirit of the present invention, the technical solutions, technical features and technical effects used in the present invention are further elaborated in conjunction with specific examples, by the following The embodiments further illustrate the present invention, and the claims of the present invention are not limited to the examples of implementation.

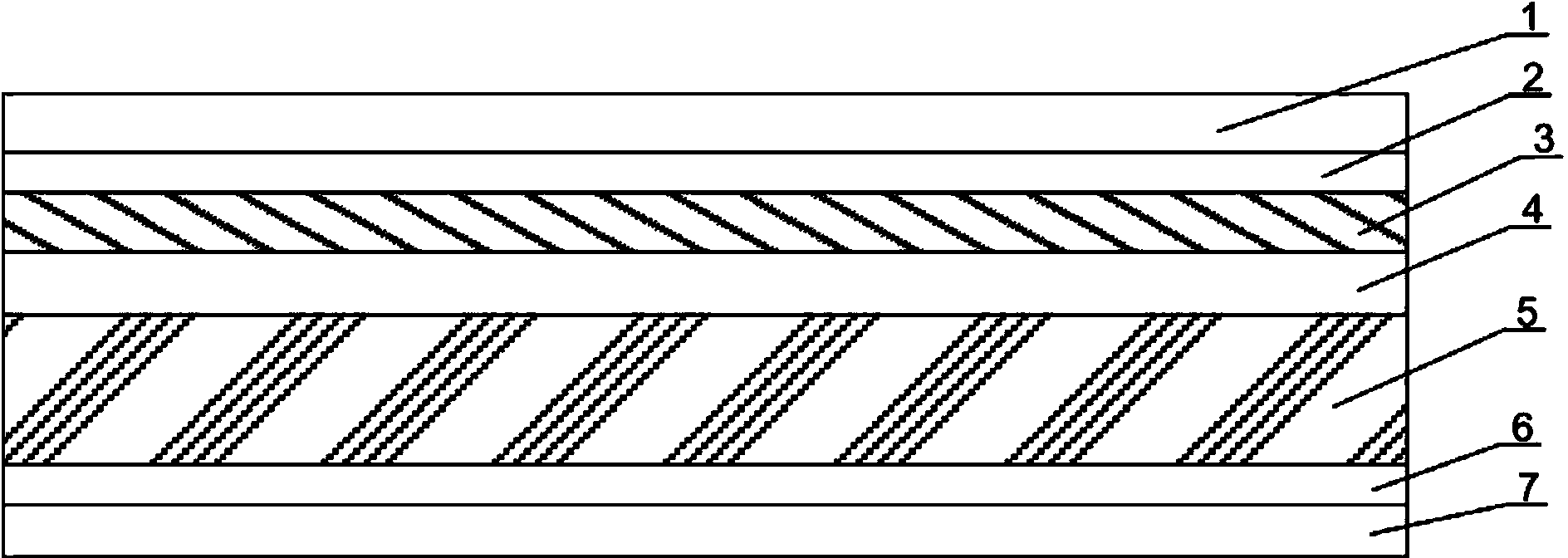

[0026] The present invention includes: a protective film layer 1 made of PET material with a thickness of 50 μm, an adhesive layer A 2 with a thickness of 10 μm, an anti-scratch layer 3 with a thickness of 3 μm, an anti-blue light layer 4 with a thickness of 4 μm, and a PET material with a thickness of 100 μm The main film layer 5, the B adhesive layer 6 with a thickness of 20 μm, and the peeling layer 7 of PET material (polyethylene terephthalate) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com