A method for cleaning pipeline slag accumulation without disassembly in zinc hydrometallurgy

A technology for hydrometallurgical zinc smelting and pipeline slag accumulation, which is applied to the improvement of process efficiency, metal recovery, recycling technology and other directions to achieve the effects of good effect, fast slag accumulation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

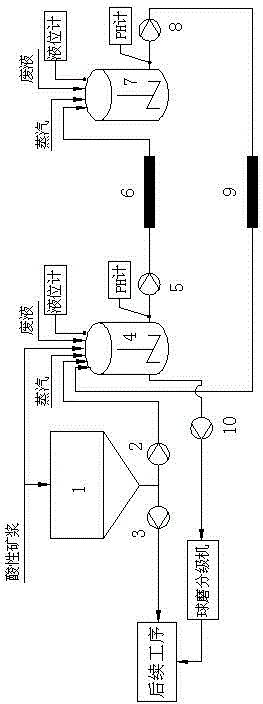

[0016] refer to figure 1 , a device for cleaning pipeline slag accumulation without disassembly in zinc hydrometallurgy, comprising an acid concentration tank 1, an underflow intermediate tank 4, an underflow circulation tank 7, a slag removal pump 5, a first slag accumulation pipeline 6, an underflow circulation pump 8, The second slagging pipeline 9, the bottom of the acid concentration tank 1 is connected with a branch pipeline, one end of the branch pipeline is connected to the underflow intermediate tank 4 through the underflow diversion pump 2, and the other end is connected to the lower process pipeline through the delivery pump 3, the said The acid concentration tank 1 and the underflow intermediate tank 4 are provided with an acid slurry delivery pipeline, the bottom of the underflow intermediate tank 4 is connected to two pipelines, one pipeline is connected to the underflow circulation tank through the slag cleaning pump 5 and the first slag accumulation pipeline 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com