A kind of processing method of copper-cobalt ore

A treatment method, copper-cobalt technology, applied in the field of hydrometallurgy, can solve the problems of large consumption of alkaline substances, etc., achieve the effects of easy transformation, simple process flow, and reduced loss of sulfuric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

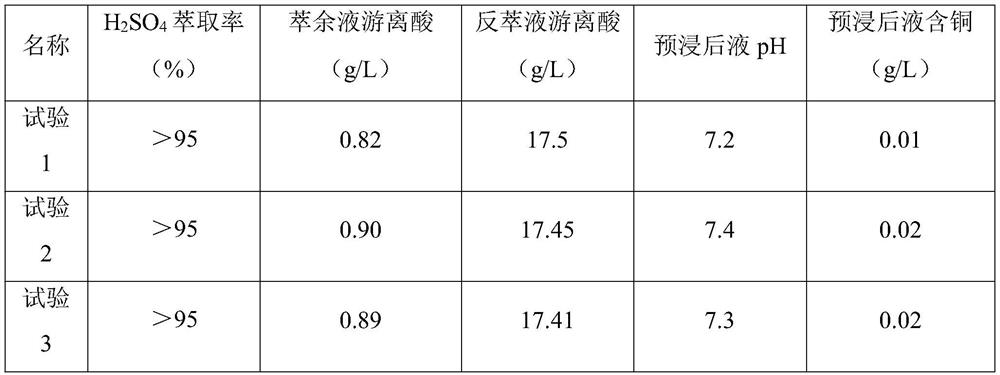

[0026] Sulfuric acid recovery and lime consumption reduction test in a copper-cobalt ore hydrometallurgy plant.

[0027] Copper-cobalt associated ore, low-copper raffinate is used as raw material of cobalt system to produce crude cobalt hydroxide, and iron removal process consumes a lot of lime. The composition of the low-copper raffinate is as shown in Table 1:

[0028] Table 1 Components of low-copper raffinate

[0029] name Cu(g / L) Co (g / L) Fe(g / L) Mn(g / L) h 2 SO 4 (g / L)

Flow (m 3 / d)

Low Copper Raffinate 0.12 4.32 3.21 2.75 18.50 8500

[0030] The iron removal process must first neutralize free sulfuric acid, which not only increases lime consumption, but also cannot recycle sulfuric acid. Lime consumption is 25kg / m 3 Low copper raffinate, in which lime used to neutralize sulfuric acid exceeds 42% of total consumption.

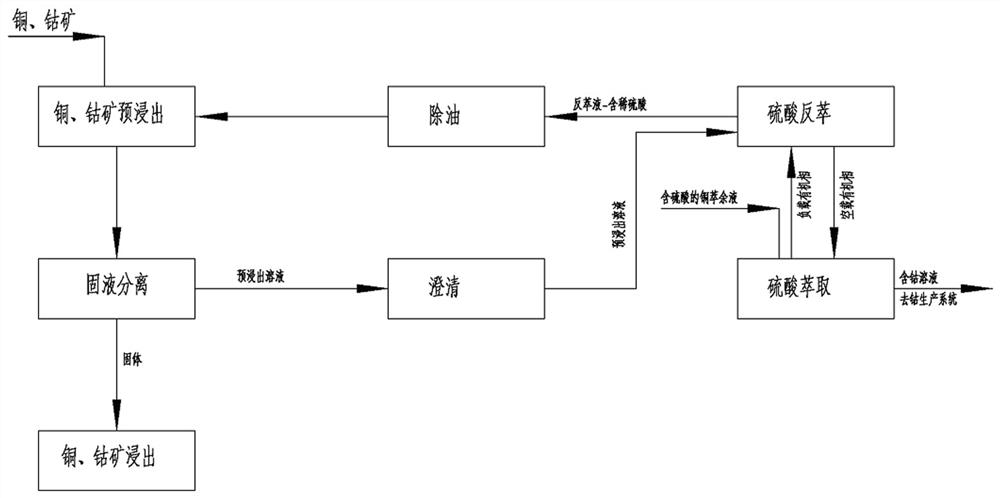

[0031] This embodiment adopts as figure 1 The process flow diagram shown.

[0032] Test plan: Most of...

Embodiment 2

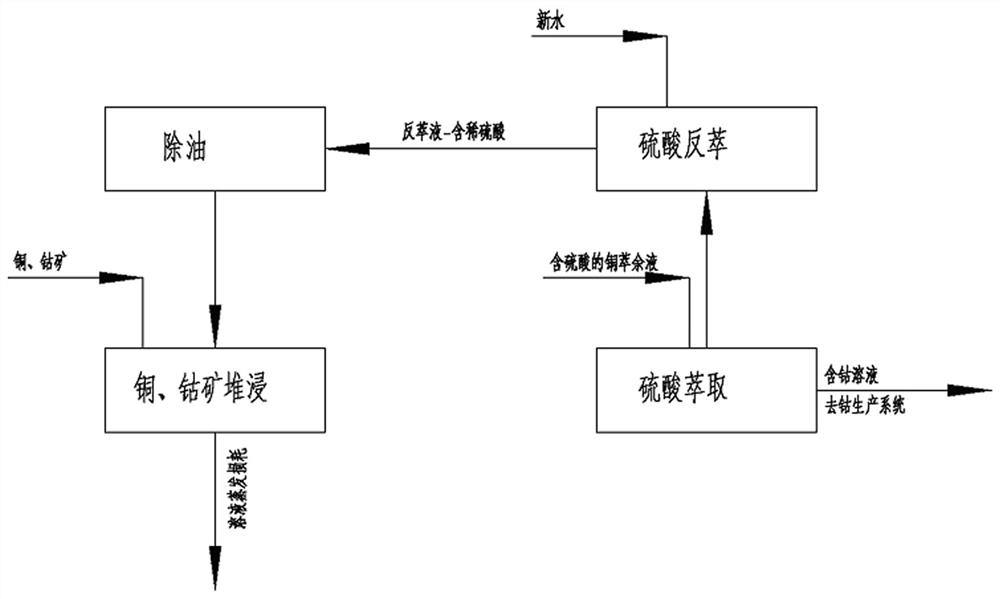

[0042] Sulfuric acid recovery, reduction of lime consumption and heap leaching test of low-grade copper ore in a copper-cobalt ore hydrometallurgy plant.

[0043] Copper-cobalt associated ore can be divided into stirring leaching and heap leaching. Stirring and leaching treatment of high-copper and low-cobalt (Cu greater than 1.5%, Co> 0.2%) ores, the products are cathode copper and crude cobalt hydroxide, and the low-copper raffinate is used as the raw material of the cobalt system to produce crude cobalt hydroxide; heap leaching treatment Low-copper and low-cobalt (Cu<1.5%, Co<0.2%) ore, the product is cathode copper, and no crude cobalt hydroxide is produced. The low-copper raffinate composition is as shown in Table 3:

[0044] Table 3 Components of low-copper raffinate

[0045] name Cu(g / L) Co (g / L) Fe(g / L) Mn(g / L) h 2 SO 4 (g / L)

[0046] The iron removal process must first neutralize free sulfuric acid, which not only increases lime consumption, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com