Planar clipping fixer with crease-resistant function

A fixer and plane technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of affecting the appearance of fabrics, easy movement of fabrics, troublesome processing, etc., and achieve the effect of convenient use, simple structure, and avoiding indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

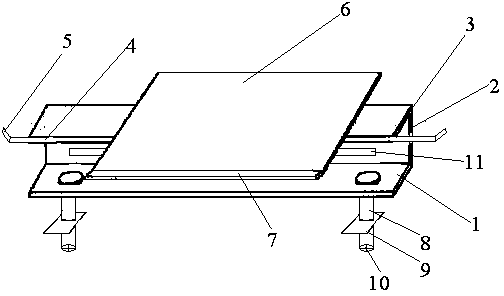

[0013] In order to further understand the planar cutting fixer with anti-wrinkle function, the description is as follows with reference to the accompanying drawings.

[0014] A plane cutting fixer with anti-wrinkle function, which includes: a base, a support plate and a fixing plate, the support plate is fixed on the base, the locking rod passes through the base and is fixed on the base, the locking rod is fixed on the end of the base and the base The upper end is on a plane, and an anti-slip layer is provided on the plane; a baffle is set on the locking rod, and the locking rod is far away from the base end to cooperate with the locking nut through threads. There is a through hole, the beam passes through the through hole of the two pillars and is placed between the pillars, the two ends of the beam are respectively connected with the handle, the crossbeam is meshed with the gear through the contact of the pillar, the fixed plate is installed on the crossbeam, and the turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com