Wind wheel locking device of megawatt-level wind driven generator

A technology for wind turbines and locking devices, which is applied to wind turbine components, wind turbines, wind power generation, etc., can solve the problems of inability to guarantee the best position of the manhole, increasing the risk factor, and low hole alignment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

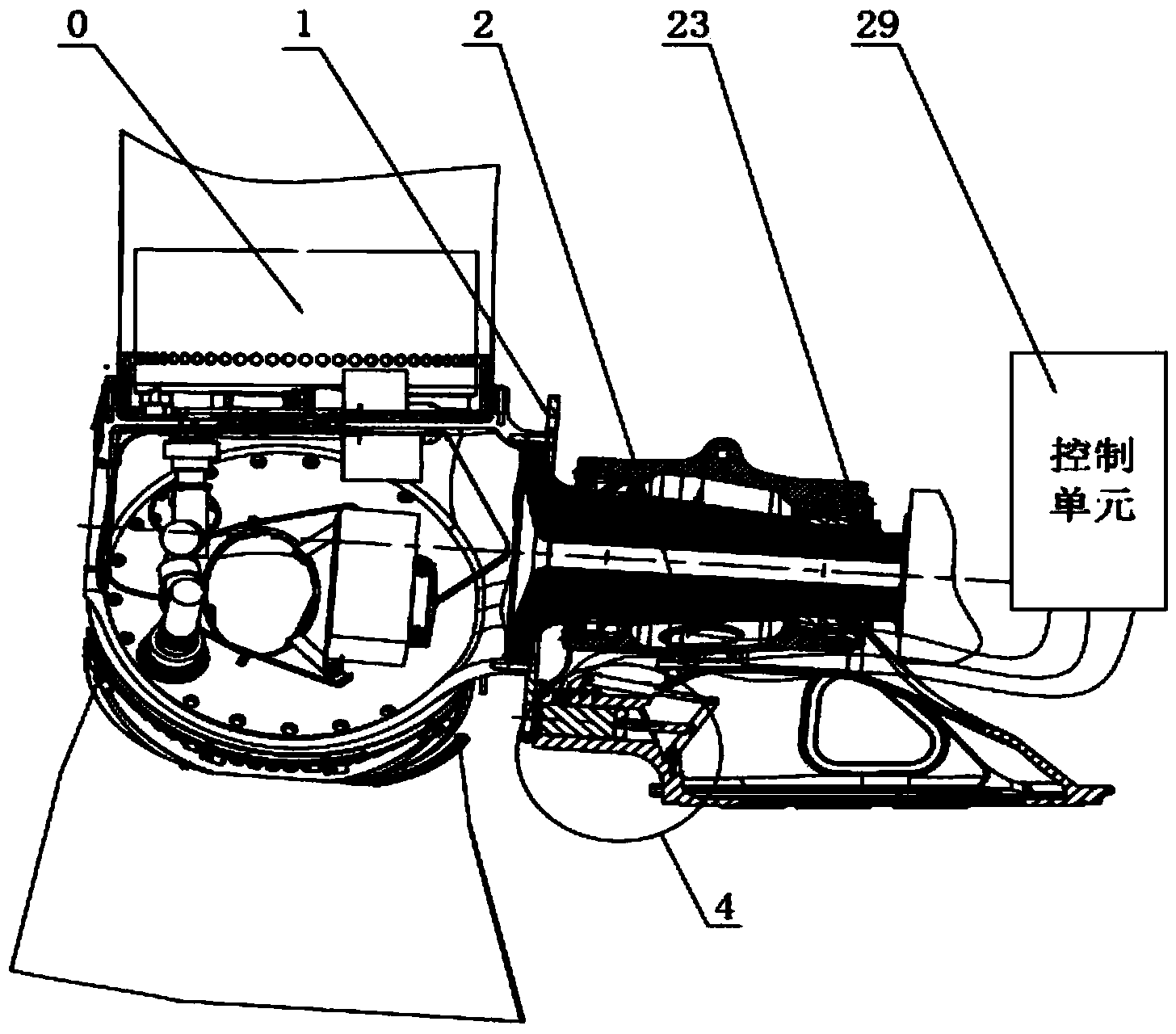

[0020] Such as figure 1 As shown, this embodiment involves: wind wheel 0, wind wheel locking disc 1, rotational speed positioning sensor 2, wind wheel locking mechanism 3, control unit 29, wherein: the wind wheel is locked 0 is the locking object, and the wind wheel locking disc 1 Rotation speed positioning sensor connected to wind wheel 0 2 Determine the position of the wind wheel through optical signals, the control unit 11 outputs a drive signal according to the optical signal, drives the wind wheel to rotate to the position that needs to be locked, and the control unit 29 sends out a wind wheel alignment signal , Drive the actuator wind wheel locking mechanism 11 to realize the purpose of locking the wind wheel.

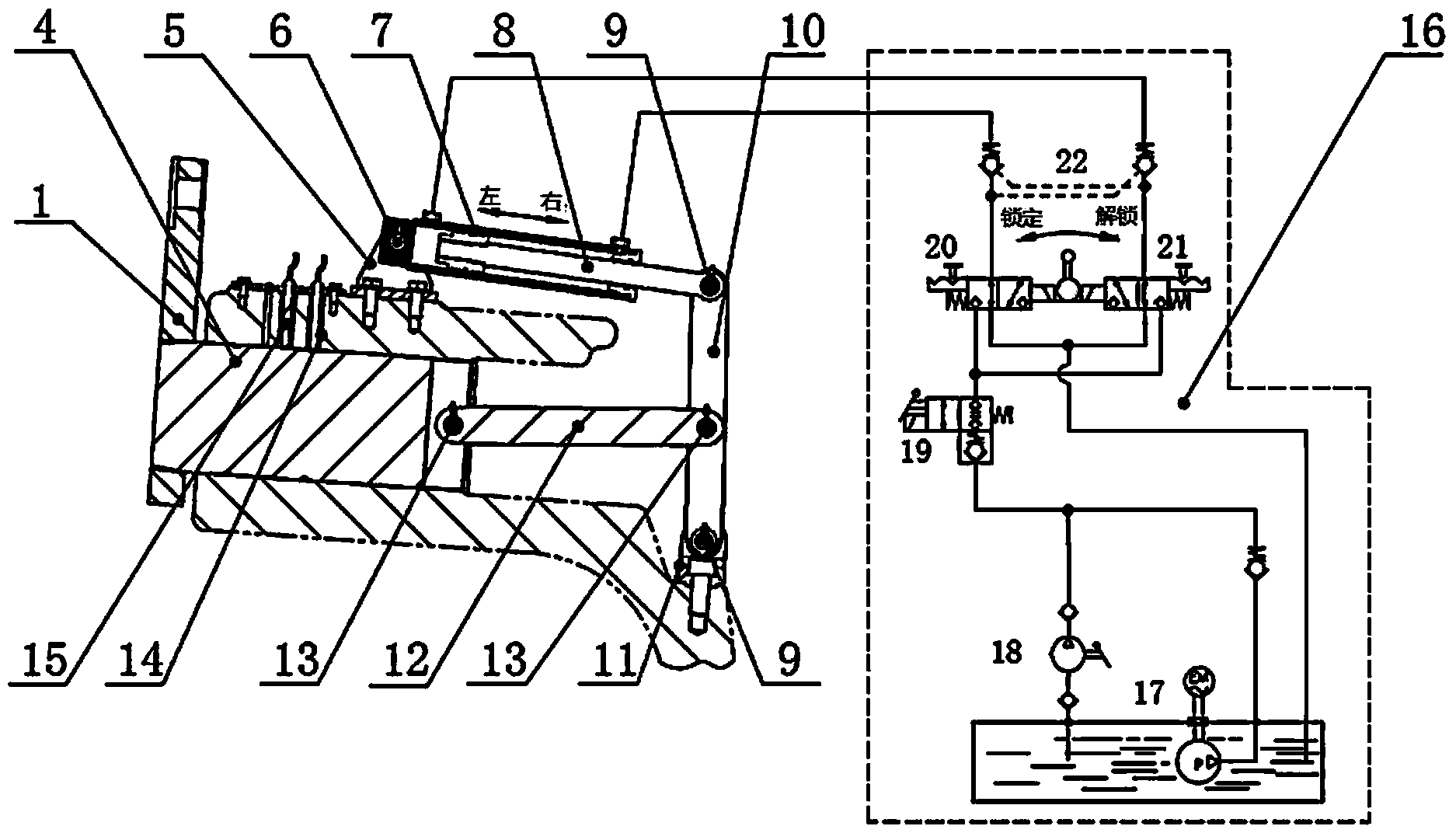

[0021] The said wind wheel locking mechanism 3 includes: wind wheel locking pin 4, hydraulic cylinder support 5, first cylindrical pin 6, hydraulic cylinder 7, cylinder connecting rod 8, second cylindrical pin 9, rotating rod 10, rotating rod support The seat 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com