Sound reducing box of single-stage high-speed blower

A blower and silencer box technology, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems that the fan cannot work, the fan cannot dissipate heat in time, and the ventilation effect is poor, so as to achieve the effect of easy transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

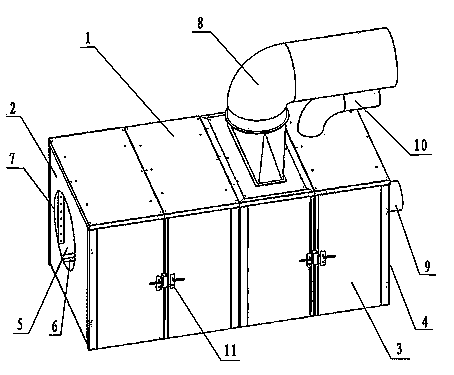

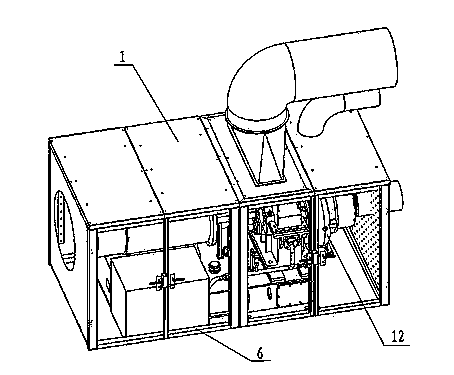

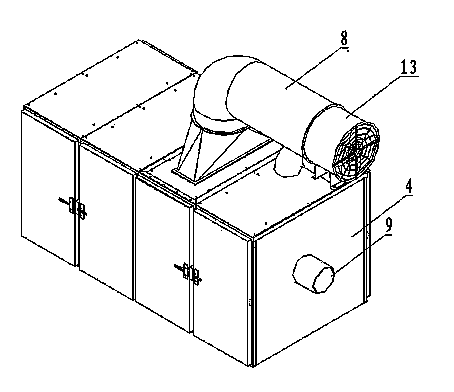

[0015] Example 1, figure 1 It is a structural schematic diagram of the present invention, figure 2 A schematic diagram showing the internal structure of the box, image 3 It is another azimuth view equipped with an axial flow fan, Figure 4 for image 3 Another azimuth view of the present embodiment is a single-stage high-speed blower silencer box, which is composed of a box body, a cooling air inlet hole 7, a cooling air outlet pipe 8, and an axial flow fan 13. The box body is composed of a top plate 1, a left side Board 2, front board 3, right side board 4, back board 5 and frame 6; top board 1 is equipped with cooling air outlet pipe 8, and there are installation holes for blower outlet pipe 10; cooling air outlet pipe 8 is installed There is an axial flow fan 13; the cooling air inlet hole 7 is opened on the left side panel 2; the front panel 3 and the back panel 5 are provided with a door leaf, the door leaf is equipped with a door bolt handle 11, and the back panel 5...

Embodiment 2

[0016] Example 2, the above-mentioned single-stage high-speed blower silencer box, the inside of the box and the door leaf are made of sound-absorbing orifice plates, and the outside is made of galvanized plates, and the space between the sound-absorbing orifice plates and the galvanized plates is filled with sound-insulating materials.

Embodiment 3

[0017] Embodiment 3, a single-stage high-speed blower silencer box described above, the box body is assembled from unit modules, the top plate 1 is divided into a plurality of unit modules, and one of the unit modules is equipped with a cooling air outlet pipe 8 , the other unit module has a blower outlet pipe 10 installation holes; the front panel 3 and the back panel 5 are door unit modules, the left panel 2 and the right panel 3 are independent opening unit modules, and the frame 6 is an independent unit Modules, select unit modules and quantities of different specifications according to the size of the fan, and assemble them on the frame 6, which is designed to be convenient for transportation and installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com